13

MECHANICAL ADJUSTMENT

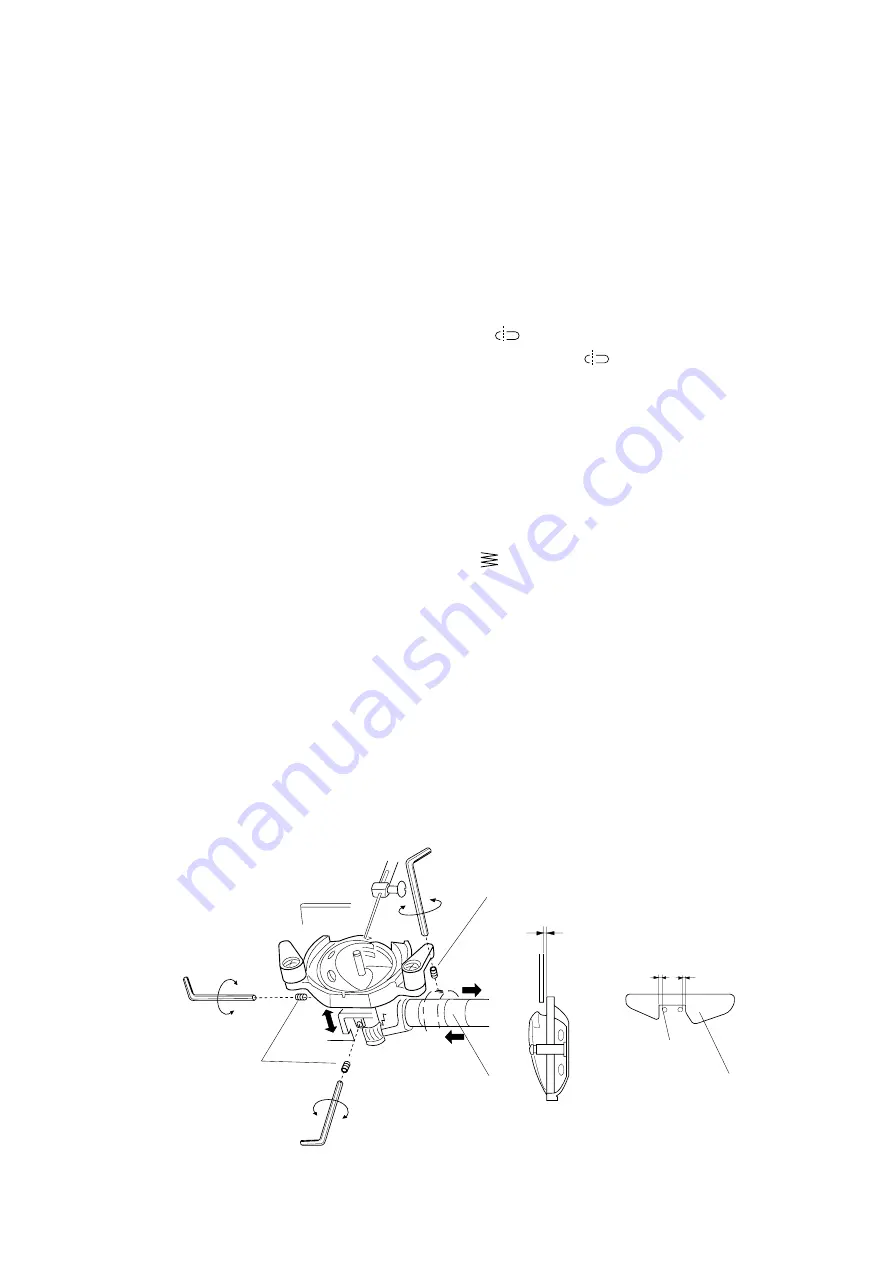

CLEARANCE BETWEEN NEEDLE AND HOOK (NO.2)

TO CHECK:

USE THIS ADJUSTMENT NO.2 WHEN ADJUSTMENT NO.1 CAN NOT BE USED.

THE CLEARANCE BETWEEN NEEDLE AND SHUTTLE RACE SHOULD BE –0.05 - +0.10mm.

ADJUSTMENT PROCEDURE:

1.

SET THE PATTERN SELECTOR DIAL AT “ ”.

MODEL 2149SX, 2149, CJ24 PATTERN SELECT DIAL " ",WIDTH SELECTOR CONTROL

AT " 0 ".

2.

REMOVE THE REAR COVER. (SEE PAGE 6.)

3.

LOOSEN THE SCREW (A) ON LOWER SHAFT BUSHING AND SLIDE THE GEAR ABOUT

0.5MM TO THE RIGHT TO MAKE A SLACK BETWEEN GEARS.

4.

LOWER THE NEEDLE AND LOOSEN THE TWO SHUTTLE RACE SET SCREWS (B).

MOVE THE SHUTTLE RACE UNIT AXIALLY EITHER FORWARD OR BACKWARD TO

ADJUST THE CLEARANCE BETWEEN THE NEEDLE AND THE SHUTTLE RACE IN THE

RANGE OF –0.05 – +0.10MM.

5.

SET THE PATTERN SELECT DIAL AT “ ”, TURN THE BALANCE WHEEL TO CHECK

IF THE CLEARANCE BETWEEN THE NEEDLE AND INNER EDGES OF THE SHUTTLE

RACE SPRING AT THE LEFT AND RIGHT NEEDLE DROPS ARE EQUAL.

IF NOT, MAKE AN ADJUSTMENT BY TURNING THE SHUTTLE RACE UNIT.

6.

TIGHTEN THE TWO SHUTTLE RACE SET SCREWS (B).

7.

LOOSEN THE SET SCREW ON LOWER SHAFT BUSHING AND SLIDE THE GEAR BACK

TO THE ORIGINAL POSITION WHILE ADJUSTING THE BACKLASH.

8.

TIGHTEN THE SCREW (A) FIRMLY.

9.

ATTACH THE REAR COVER.

NOTE: THE BACKLASH PLAY SHOULD BE LESS THAN 0.3MM AND LOWER SHAFT

TURNS SMOOTHLY.

AFTER THE ADJUSTMENT, CHECK THE HOOK TIMING.

SET SCREW A

–0.05-+0.10MM

CLEARANCE SHOULD BE EQUAL

SHUTTLE RACE

SET SCREW B (2 PCS.)

LOWER SHAFT

BUSHING (FRONT)

NEEDLE

SHUTTLE RACE SPRING