Light

weight

Medium

weight

Heavy

weight

Fabrics

-----

- ----------

Crepe de Chine, Voile,

Lawn, Organdy,

Georgette,

Tricot

- --------------

Linens1 Cotton, Pique,

Serge, Double Knits,

Percale

Denim, Tweed,

Gabardine,

Coating, Drapery and

Upholstery

Fabric

Thread

Fine Silk

Fine Cotton

Fine Synthetic

Fine Cotton

Covered

Polyester

50

silk

50

to

BO

Cotton

50

to

60

Synthetic

Cotton Covered

Polyester

50

silk

40

to

50

Cotton

40

to

50

Synthetic

Cotton Covered

Polyester

Size

9

o r

11

11

or

14

14

16

5

Changing Needle

Raise the needle by turning the handwheel

toward you and lower the presser foot.

Loosen the needle clamp screw by turning it

counterclockwise.

Remove the needle from the clamp.

Insert the new needle into the clamp with the flat

side away from you.

When inserting the needle into the clamp, push

it up as far as it will go and tighten the clamp

screw firmly with the screwdriver.

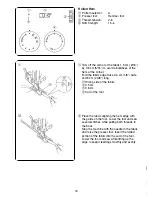

*

Check your needles frequently for barbed or

blunted points. Snags and runs in knits, fine

silks and silk-like fabrics are permanent and

are almost always caused by a damaged

needle.

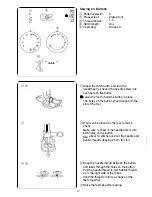

To check the Needle

Place the flat side of the needle on something flat

(needle plate, glass etc.). The clearance between

the needle and flat surface should be consistent.

Never use a bent or blunt needle.

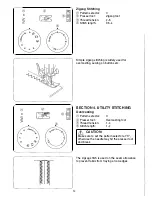

Thread and Needle Chart

* In general, fine threads and needles are used

for sewing thin fabrics, and thicker threads

and needles are used for sewing heavy

fabrics. Always test thread and needle size

on a small piece of fabric which will be used for

actual sewing.

•

Use the same thread for needle and bobbin.

•

When sewing stretch, very fine fabrics and

synthetics, use a BLUE TIPPED needle.

The blue tipped needle effectively prevents

skipped stitches.

•

When sewing very fine fabrics, sew over a piece

of paper to prevent seam puckering.