19

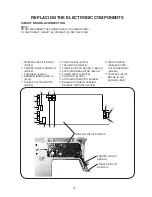

correct condition

Step and

itemS to

check

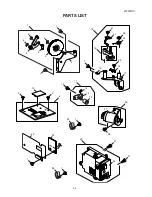

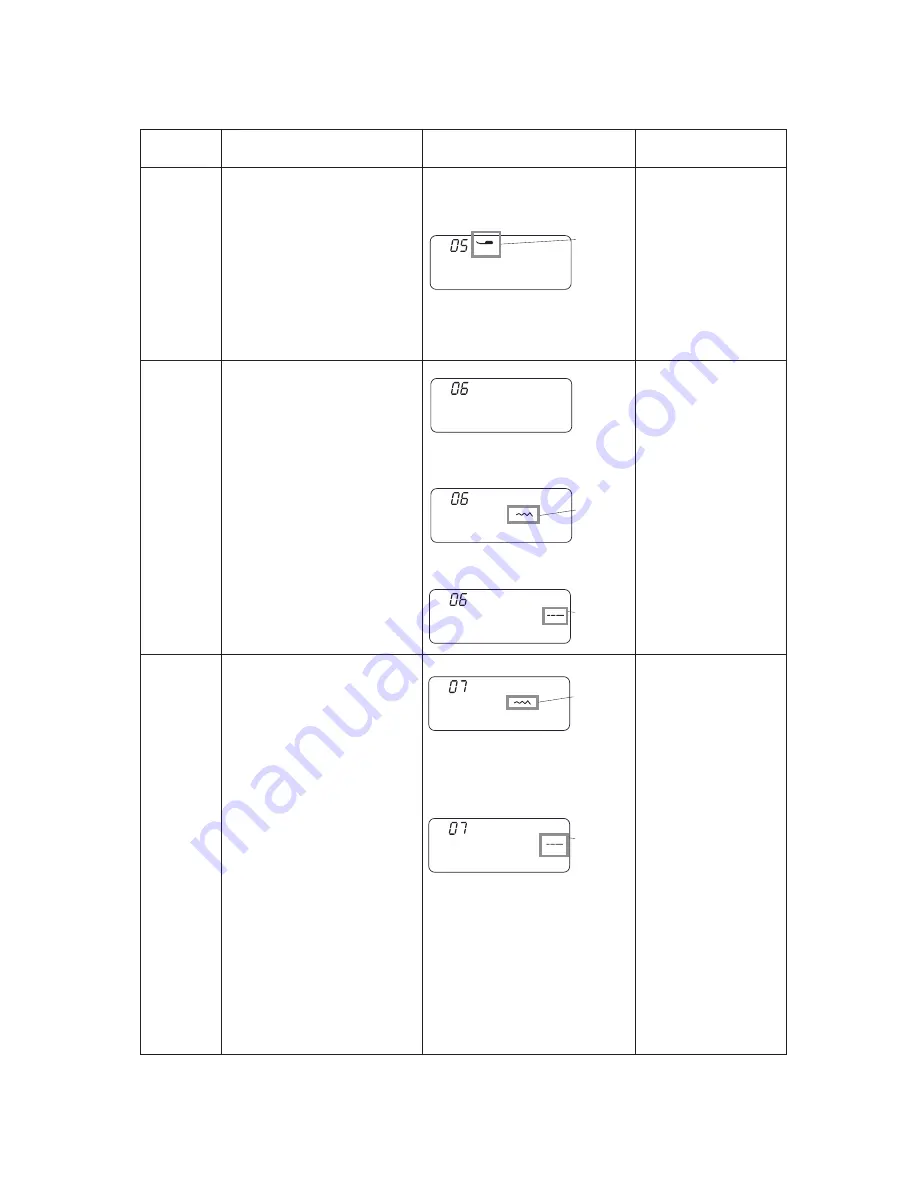

05)

preSSer

foot lifter

Switch

procedUre

defective condition

tUrn the handwheel toward

yoU.

lower the needle bar from

itS higheSt to itS loweSt

poSition.

raiSe the needle bar from

itS loweSt poSition to itS

higheSt poSition.

if the reSUlt iS correct

condition, preSS the Start/

Stop bUtton to proceed the

next Step.

if the reSUlt iS defective

condition, preSS the reverSe

Stitch bUtton to proceed the

next Step.

bUzzer doeS not SoUnd.

Stitch width or length Sym-

bol doeS not appear.

–Remedy–

replace the circUit board a.

replace the circUit board p.

zigzag motor doeS not get

defaUlt poSition.

bUzzer doeS not SoUnd.

–Remedy–

replace the zigzag motor.

replace the circUit board a.

feed motor doeS not get

defaUlt poSition.

bUzzer doeS not SoUnd.

–Remedy–

replace the feed motor.

replace the circUit board a.

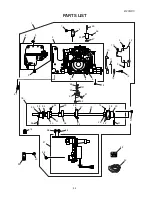

06)

Upper

Shaft

poSitioning

SenSor

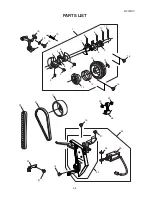

07)

zigzag

motor

(Step

motor)

and

feed

motor

tUrn the handwheel toward

yoU.

lower the needle bar itS

higheSt to poSition (zigzag

phaSe)

.

preSS the needle Up/down

bUtton.

raiSe the needle bar from

itS loweSt poSition to itS

higheSt poSition (feed phaSe).

preSS the needle Up/down

bUtton.

if the reSUlt iS correct

condition, preSS the Start/

Stop bUtton to proceed the

next Step.

if the reSUlt iS defective

condition, preSS the reverSe

Stitch bUtton to proceed the

next Step.

lcd diSplayS “06”.

tUrn the handwheel.

lcd diSplayS Stitch width Sym-

bol when the needle bar iS at

zigzag phaSe.

Stitch

width

Symbol

Stitch

length

Symbol

lcd diSplayS Stitch length Sym-

bol when the needle bar iS at

feed phaSe.

lcd diSplayS “07”.

preSS the needle Up/down bUt-

ton when lcd diSplayS Stitch

width Symbol.

the zigzag motor will be initial-

ized and get itS defaUlt poSi-

tion.

Stitch

width

Symbol

self-diagnostiC test

move the preSSer foot lifter

Up and down.

if the reSUlt iS correct condi-

tion, preSS the Start/Stop bUt-

ton to proceed the next Step.

if the reSUlt iS defective

condition, preSS the reverSe

Stitch bUtton to proceed the

next Step.

lcd diSplayS “05”.

when the preSSer foot lifer iS

lowered, bUzzer SoUndS and lcd

diSplayS preSSer foot Symbol.

when the bUttonhole lever iS

raiSed, bUzzer SoUndS and the

preSSer foot Symbol diSappearS.

presser

foot symbol

bUzzer doeS not SoUnd.

preSSer foot Symbol doeS

not appear.

–Remedy–

adjUSt the preSSer foot

lifter Switch poSition.

replace the preSSer foot

lifter Switch.

replace the circUit board a.

preSS the needle Up/down bUt-

ton when lcd diSplayS Stitch

length Symbol.

the feed motor will be initial-

ized and get itS defaUlt poSi-

tion.

Stitch

length

Symbol