16

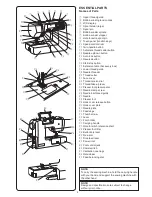

Changing the Needle

CAUTION:

Turn OFF the power switch before changing the

needle.

Raise the needle to its highest position by turning the

handwheel counterclockwise, and lower the presser

foot.

A loose needle or a loose screw may cause machine

malfunction or needle to break.

Loosen the needle clamp screw by turning it

counterclockwise. Remove the needle from the needle

clamp.

Insert a new needle into the needle clamp with the flat

side to the rear. When inserting the needle into the

needle clamp, push it up as far as it will go.

Tighten the needle clamp screw firmly by turning it

clockwise.

q

Needle clamp screw

w

Flat side

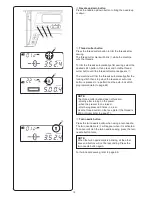

To see if the needle is in good condition, place the flat

side of the needle onto something flat (needle plate, glass

etc.). The gap between the needle and the flat surface

should be consistent. Never use a bent or blunt needle.

A damaged needle can cause permanent snags or runs

in knits, fine silks and silk like fabrics.

q

w

Summary of Contents for 4300QDC

Page 1: ...Instruction Book 4300QDC...

Page 79: ...77 Stitch Chart...

Page 80: ...78 Stitch Chart...

Page 82: ...80 Version 1 00 12 6 2018...

Page 83: ......

Page 84: ...809 850 956 EN...