26

LCD displays “04”.

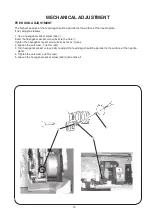

When the bobbin winder spindle is

moved to the right, buzzer sounds and

LCD displays the bobbin symbol.

When the bobbin winder spindle is

moved to the left, buzzer sounds and

LCD displays “04”.

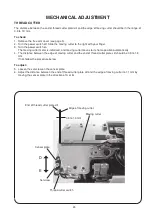

CORRECT CONDITION

Sewing lamp and LCD backlight lit.

LCD displays “----”.

01)

FUNCTION OF

LCD, BUZZER

AND LAMP

PROCEDURE

Turn on the power switch while

simultaneously pressing the

needle up/down button and thread

cutter button.

Press the needle up/down button

within the 1.5 seconds to enter the

self-diagnostic mode.

Press the “1” key.

If the result is correct condition, press

the start/stop button to proceed the

next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

DEFECTIVE CONDITION

Sewing lamp does not lit.

LCD backlight does not lit.

LCD does not display.

Buzzer does not sound.

LCD does not turned on.

LCD does not display any

symbols or not in order.

–REMEDY–

Replace the printed circuit

board A.

Replace the machine lamp.

Replace the touch panel.

Replace the printed circuit

board F.

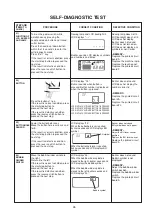

Buzzer sounds. LCD displays symbols

and numbers and blinks.

LCD displays “02”.

Buzzer sounds when button is

pressed. Button number is displayed

when the button is pressed.

LCD DISPLAYS “S1” WHEN BUTTON 1 IS PRESSED.

LCD DISPLAYS “S2” WHEN BUTTON 2 IS PRESSED.

LCD DISPLAYS “S3” WHEN BUTTON 3 IS PRESSED.

LCD DISPLAYS “F3” WHEN BUTTON 4 IS PRESSED.

LCD displays “03”.

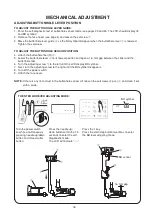

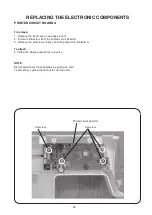

When the buttonhole lever is pulled,

buzzer sounds and LCD displays BH

symbol.

BH symbol

Bobbin symbol

Press the buttons 1 to 4.

If the result is correct condition, press

the start/stop button to

proceed the next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

Lower the buttonhole lever.

Move the buttonhole lever back and

forth.

If the result is correct condition, press

the start/stop button to proceed the

next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

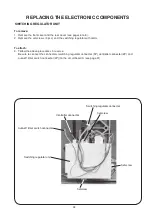

Move the bobbin winder spindle to

the right.

Return it to the left.

If the result is correct condition, press

the start/stop button to

proceed the next step.

If the result is defective condition,

press the reverse stitch button to

proceed the next step.

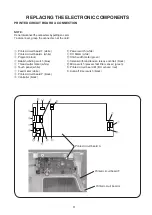

1

4

3

2

02)

BUTTON

03)

BUTTONHOLE

SENSOR

SELF-DIAGNOSTIC TEST

STEP AND

ITEMS T

O

CHECK[

04)

BOBBIN

WINDER

SWITCH

When the buttonhole lever is pushed,

buzzer sounds and LCD displays BH

symbol.

Buzzer does not sound.

LCD does not display the

number correctly.

–REMEDY–

Replace the printed circuit

board A.

Replace the printed circuit

board F2.

Buzzer does not sound.

BH symbol does not appear.

–REMEDY–

Adjust the BH lever sensor

position.

Replace the BH lever sensor.

Replace the printed circuit

board A.

Buzzer does not sound.

Bobbin symbol is not

displayed.

–REMEDY–

Adjust the bobbin winder

switch position.

Replace the bobbin winder

switch.

Replace the printed circuit

board A.

Summary of Contents for 5270QDC

Page 1: ...First Edition 06 March 2020 SERVICE MANUAL PARTS LIST MODEL 5270QDC For Europe only...

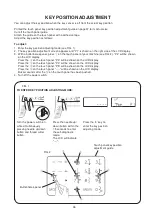

Page 39: ...37 TOUCH PANEL KEY POSITION ADJUSTMENT GUIDE Print this illustration guide to its actual size...

Page 52: ...50 MODEL 5270QDC PARTS LIST 1 2 3 4 6 5 7 8 9 10 11 12 13 14 17 15 18 19 20 9 21 21 22 23 16...