www.toews.com

12

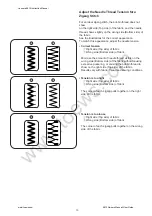

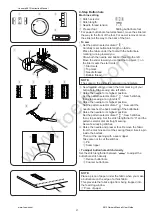

Adjust the Needle Thread Tension for a Straight

Stitch

• Correct tension

q

Needle thread (Top thread)

w

Bobbin thread (Bottom thread)

e

To loosen

r

To tighten

The ideal straight stitch has threads locked between two

layers of fabric, as illustrated (magnified to show detail).

If you look at the top and bottom of a seam, look to see

that the stitches are evenly balanced.

When adjusting the needle thread tension, the higher the

number, the tighter the top thread tension.

Results depend on:

- stiffness and thickness of the fabric

- number of fabric layers

- type of stitch

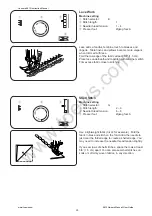

• Tension is too tight

q

Needle thread (Top thread)

w

Bobbin thread (Bottom thread)

e

To loosen tension

r

Right side (Top side) of fabric

t

Wrong side (Bottom side) of fabric

The bobbin thread shows through on the wrong side of

the fabric, and the stitch feels bumpy. Turn the dial to a

lower tension setting number to loosen the needle thread

tension.

• Tension is too loose

q

Needle thread (Top thread)

w

Bobbin thread (Bottom thread)

e

To tighten tension

r

Right side (Top side) of fabric

t

Wrong side (Bottom side) of fabric

The needle thread shows through on the wrong side

of the fabric, and the stitch feels bumpy. Turn the dial to a

higher tension setting number to tighten the needle thread

tension.

5

4

3

1

4

3

2

5

4

3

1

5

4

3

2

5

4

3

1

5

4

3

2

Janome 5812 Instruction Manual

www.toews.com

5812 Owners Manual/ User Guide