NEEDLE TO HOOK TIMING

NEEDLE TO HOOK TIMING

NEEDLE TO HOOK TIMING

NEEDLE TO HOOK TIMING

NEEDLE TO HOOK TIMING

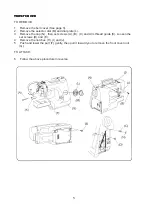

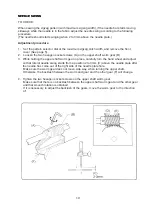

With the needle bar swung to the right at the maximum zigzag width, the amount of ascending

travel of the needle bar from its lower position to the position where the tip of the rotary hook

exactly meets the right side of the needle should be 1.4 to 2.0 mm.

Before the adjustment, be sure to check the needle bar height.

Adjustment procedure:

1.

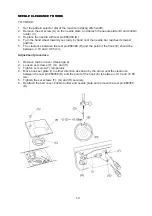

Set the pattern selector dial at maximum zigzag stitch width (stitch No. 6).

2.

Remove set screw (A) on the needle plate to remove the needle plate (B) and bobbin

holder (C).

3.

Remove the bed cover (See page 4).

4.

Loosen hexagon screws (D) on the lower shaft gear (E).

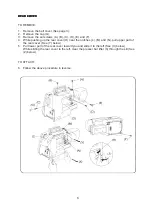

5.

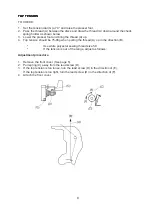

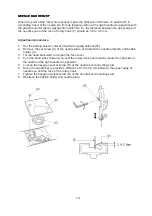

Turn the hand wheel toward you to bring the needle bar 1.4 to 2.0 mm from its lowest

position (F) with the needle swing to the right.

6.

While holding the hand wheel by hand to prevent the needle bar from moving, turn the

lower shaft gear in the direction of arrow until the tip of the rotary hook exactly meets the

right side of the needle (G).

7.

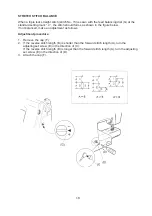

Taking care not to affect the relationship between the rotary hook tip and the needle,

tighten the hexagon screws (D) on the lower shaft gear.

8.

Attach the bed cover, bobbin holder and needle plate,

15