Securing Ends

To avoid raveling, you need to leave a thread chain

approximately

2˝ (5 cm) long at the beginning and at the

end of a seam. To secure the beginning and end of a

seam, choose one of the following methods.

At the beginning of the seam

A. Separate and tie the thread ends together.

B. Thread the chain through a large eyed needle, and

weave that chain through the overlock stitches on the

fabric.

C. Cut the chain at the edge of the fabric, and apply a

small amount of seam sealant

(Fray Check™ or Fray-

No-

More™) to the thread ends.

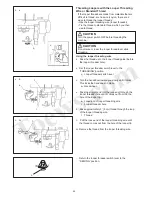

D. Securing the beginning with the machine

z

Before putting your fabric in the machine, sew a

thread chain approximately

2˝ (5 cm) long behind

the needle.

x

Put your fabric on the machine. Serge a few

stitches and stop.

c

Raise the presser foot and bring the thread chain

to the left around and under the presser foot.

v

Place the thread chain between the presser foot

and upper knife, holding it in position as you lower

the presser foot to sew.

b

After sewing approximately

1˝ (2.5 cm), move the

chain to the right and under the upper knife, cutting

the chain as you sew.

D

A

B

C

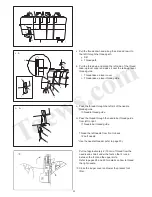

At the end of the seam

Securing the seam end with the machine

z

Serge one stitch off the end of the seam.

x

Raise the needle and presser foot, and gently pull the

threads off the chaining finger.

c

Turn the fabric over so that the under side is up.

v

Serge approximately

1˝ (2.5 cm) over the stitching and

angle off the fabric.

E

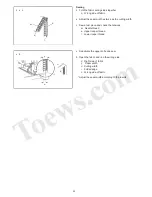

Cutting the Seams

Cut the upper looper thread with a seam ripper (not

included with the machine) to cut the seams.

q

Upper looper thread

w

Seam ripper

q

36

w

z

z

x c v b

x c

v