49

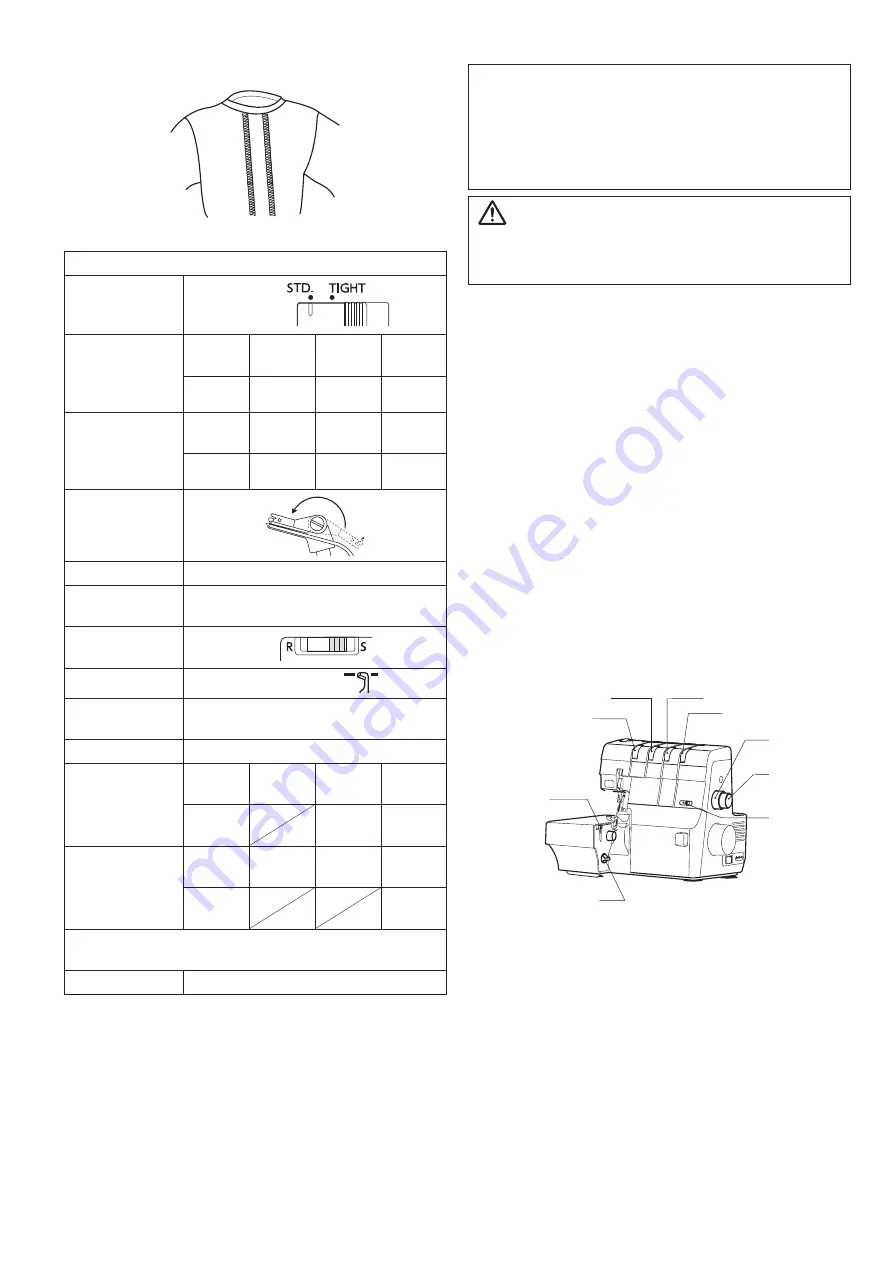

q

Left needle thread tension dial

w

Right needle thread tension dial

e

Upper looper thread tension dial

r

Lower looper thread tension dial

t

Chaining finger switch knob

y

Upper knife release knob

u

Stitch length dial

i

Differential feed dial

o

Lower looper pre-tension setting slider

* Refer to page 10 for details on how to remove the

needle.

* Refer to page 11 for details on how to adjust the

stitch length.

* Refer to page 11 for details on how to adjust the

difference ratio.

* Refer to page 12 for details on how to deactivate/

activate the upper knife.

* Refer to page 13 for details on how to adjust the

chaining finger switch knob.

* Refer to page 18 for details on how to raise and

lower the spreader.

Flatlock

CAUTION

Make sure to turn the power switch off before

changing the needle, deactivating/activating the upper

knife or setting the chaining finger switch knob.

w

q

e

r

t

y

u

i

o

Machine Setting

Lower looper

pre-tension

setting slider

STD.

Standard setting

of tension dials

(1 needle 3

threads)

Left

needle

Right

needle

Upper

looper

Lower

looper

0-2

-

0

6-7

Standard setting

of tension dials

(1 needle 2

threads)

Left

needle

Right

needle

Upper

looper

Lower

looper

0-2

-

-

7

Spreader

(1 needle 2

threads)

Stitch length dial

3-4

Differential feed

dial

1.0

Chaining finger

switch knob

S

Upper knife

Deactivated

Needle

Use the left needle:

HA-1 SP No. 14 or No. 11

Needle thread

Synthetic: No. 60 - 100

Upper looper

thread

Left

needle

Right

needle

Upper

looper

Lower

looper

Synthetic:

No.60-100

Decorative

thread

Synthetic:

No.60-100

Lower looper

thread

Left

needle

Right

needle

Upper

looper

Lower

looper

Synthetic:

No.60-100

Decorative

thread

* Use the looper threading wire or a standard thread for

threading.

Fabric

Medium weight

NOTE:

• You may need to adjust the thread tension

depending on the type of fabric and thread being

used.

• If the tension balance on the test piece is not

satisfactory, you can adjust the thread tension with

the thread tension dial.

Summary of Contents for AT2000D

Page 2: ...Instruction Book AirThread 2000D Professional...

Page 3: ......

Page 62: ...59 This page is left intentionally blank...

Page 63: ...60 Version 1 01 11 04 2018...

Page 64: ......

Page 65: ...799 800 005 EN...