49

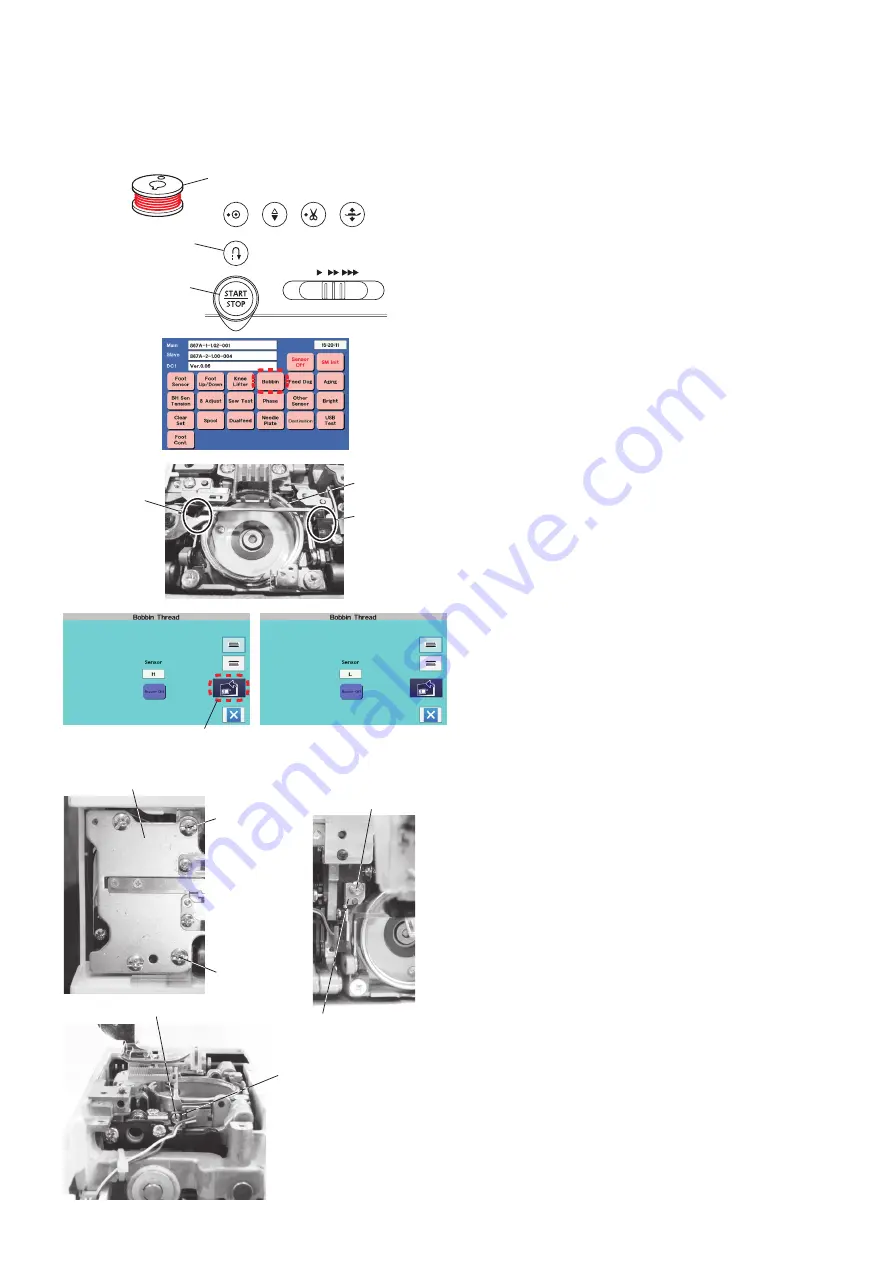

Optical bottom thread sensor adjustment

To check:

1. Prepare the wound bobbin.

2. Turn the power switch ON while pressing the start/

stop button and the reverse stitch button to enter the

factory setting mode.

Press the “Bobbin” key to select the bobbin thread

sensor adjusting mode.

3. Be sure that “Sensor” indicates “H” when the wound

bobbin is inserted.

When the bobbin is not inserted, turn the handwheel

and be sure that “Sensor” indicates “L” when the light

passes from A to B.

Be sure that “Sensor” indicates “H” when the light is

blocked by the hook and does not pass from A to B.

If not, follow the adjustment procedure below.

Reverse button

Wound bobbin

Start/stop button

Needle plate

release key

Setscrew A

Thread cutter unit

Setscrew B

Light emitting

device plate

Setscrew A

Setscrew C

To adjust:

1. Press the needle plate release key and remove the

needle plate.

2. Remove the thread cutter cover. (Refer to page 3)

3. Remove the setscrews A (2 pcs.) and thread cutter

unit.

4. Loosen the setscrews B.

Move the light emitting device plate forward and

backward to adjust the position of the plate.

5. Loosen the setscrews C.

Move the light emitting device holder up and down to

adjust the position of the holder.

After this adjustment, check if the “Sensor” indicates

correct sign at the step 3 at “To check” on this page.

Light enittibg

device holder

(A)

(B)

Hook race