34

Beginning and End of the seam

At the beginning of the seam, use a piece of scrap fabric

to achieve the best results.

At the end of the seam, you can choose either to end

sewing with the thread chain or without thread chain (A

thread chain is a chain of threads knit without fabric).

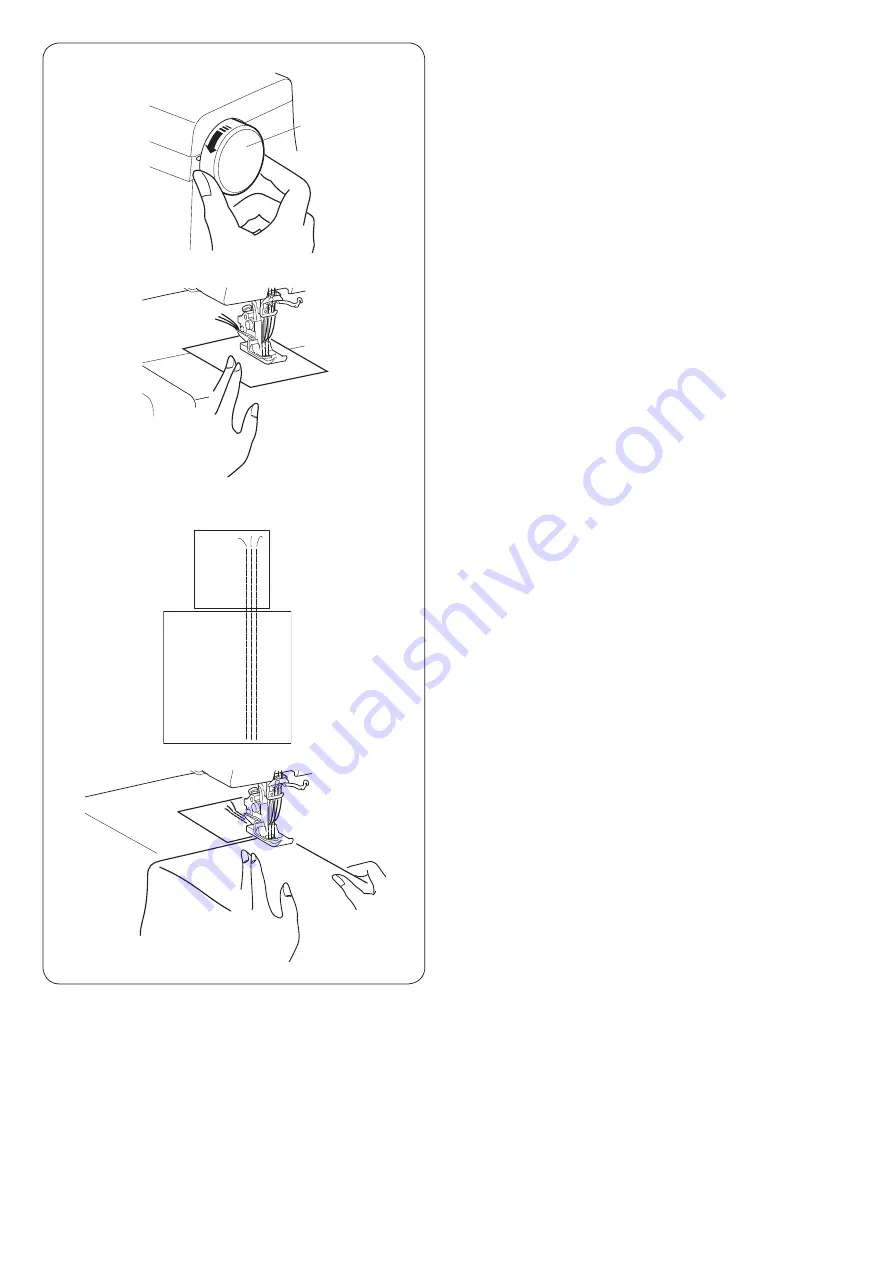

Beginning of the seam

z

Turn the handwheel toward you to bring the needle to

its highest position.

Raise the presser foot lifter and insert a piece of scrap

fabric under the foot.

Lower the presser foot lifter.

Depress the foot control to start sewing slowly.

q

Handwheel

x

Stop sewing at the end of the scrap fabric.

Insert the work fabric after the scrap as shown, then

start sewing on the work fabric.

w

Scrap fabric

e

Work fabric

w

e

z

x

q

Summary of Contents for CoverPro 3000

Page 2: ...Instruction Book...

Page 25: ...22 Threading the Top Cover Stitch Guides and Spreader...

Page 48: ......

Page 49: ...778 800 055 EN...