21

DC4030P

SELF DIAGNOSTIC TESTS

CORRECT CONDITION

STEP

06)

Buttonhole

sensor

OPERATION

DEFECTIVE CONDITION

Press needle up/down button, LED

displays "06" for one second.

1. Lower the buttonhole lever.

2. Move the buttonhole lever back and

forth.

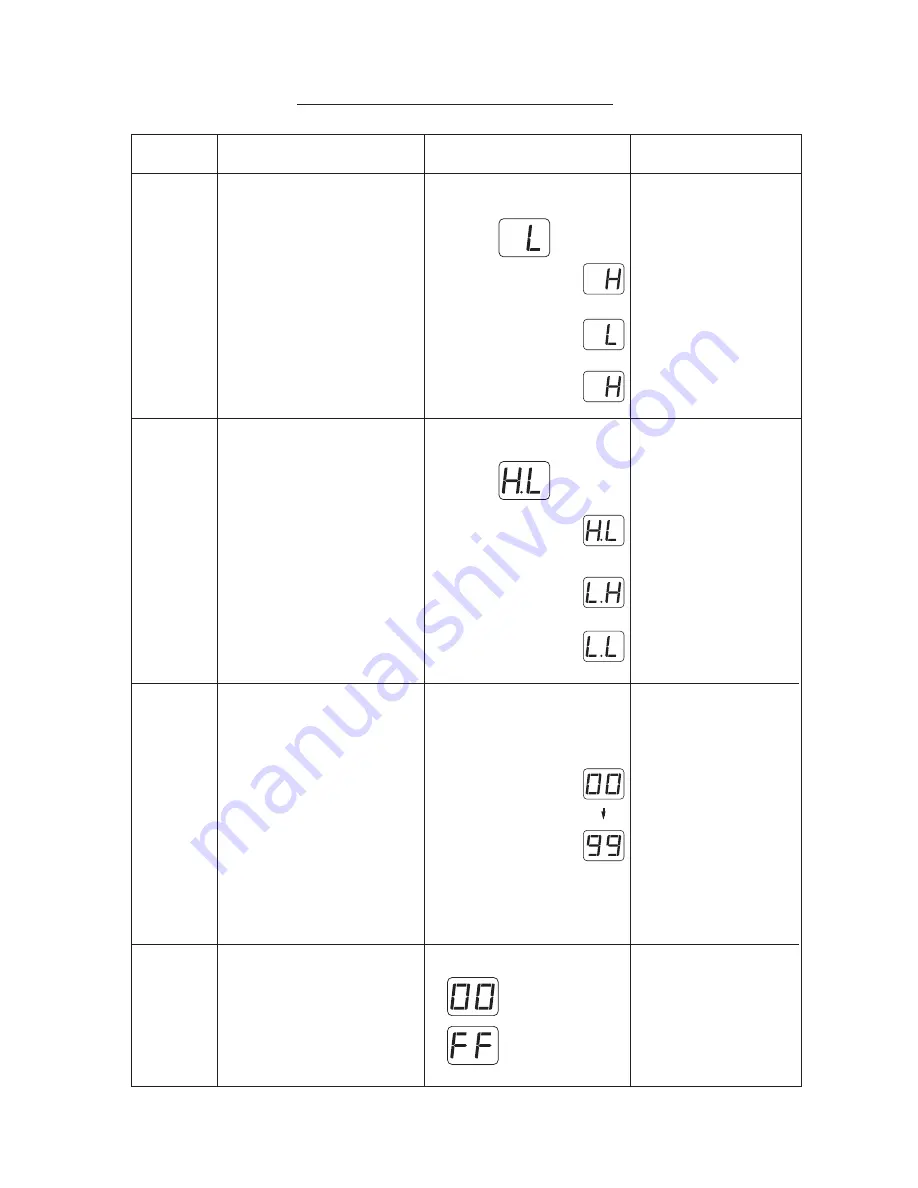

* LED indicates "L" or "H".

* When the buttonhole lever

is pulled, LED displays "H".

* When the buttonhole lever

is free (positioned in the

center), LED displays "L".

* When the buttonhole lever

is pushed, LED displays

"H".

LED display is different from

that shown to the left.

1. Adjust the buttonhole

sensor position.

2. Replace buttonhole

sensor.

3. Replace board "A".

07)

Upper shaft

sensor

Press the needle up/down button,

LED displays "07" for one second.

* Turn the handwheel toward you to

raise and lower the needle to its

highest and lowest position.

* LED indicates "H.L".

* When the needle is at

the highest position,

LED displays "HL".

* When the needle is at

the lowest position,

LED displays "LH".

* When the needle is halfway,

LED displays "LL".

* LED display is different from

that shown to the left.

1. Adjust upper shaft shield

plate.

2. Replace upper shaft sensor.

3. Replace board "A".

08)

Sewing

speed

sensor

* Press the needle up/down button.

LED displays "08" for one second.

* Turn the handwheel clockwise by

hand and check the counter value

displayed.

* LED displays "00" first and the indi-

cates value increases as you turn the

handwheel.

(When the value

reaches 100, it will

return to "00" and one

mode LED lights up.

For example, 2 mode

LEDs and "78" means

"278".)

The maximum value

should be 370 to 390.

* LED displays different from

that shown to the left.

1. Replace motor.

2. Replace board "A".

LED

LED

09)

Slide

volume

* Press the needle up/down button.

LED displays "09" for one second.

* Slide the speed control lever from the

left to the right, then return it to the

left.

* LED indicates "00".

(At left position)

(At right position)

* LED display is different from

that shown to the left.

1. Replace slide volume.

2. Replace board "A".