14

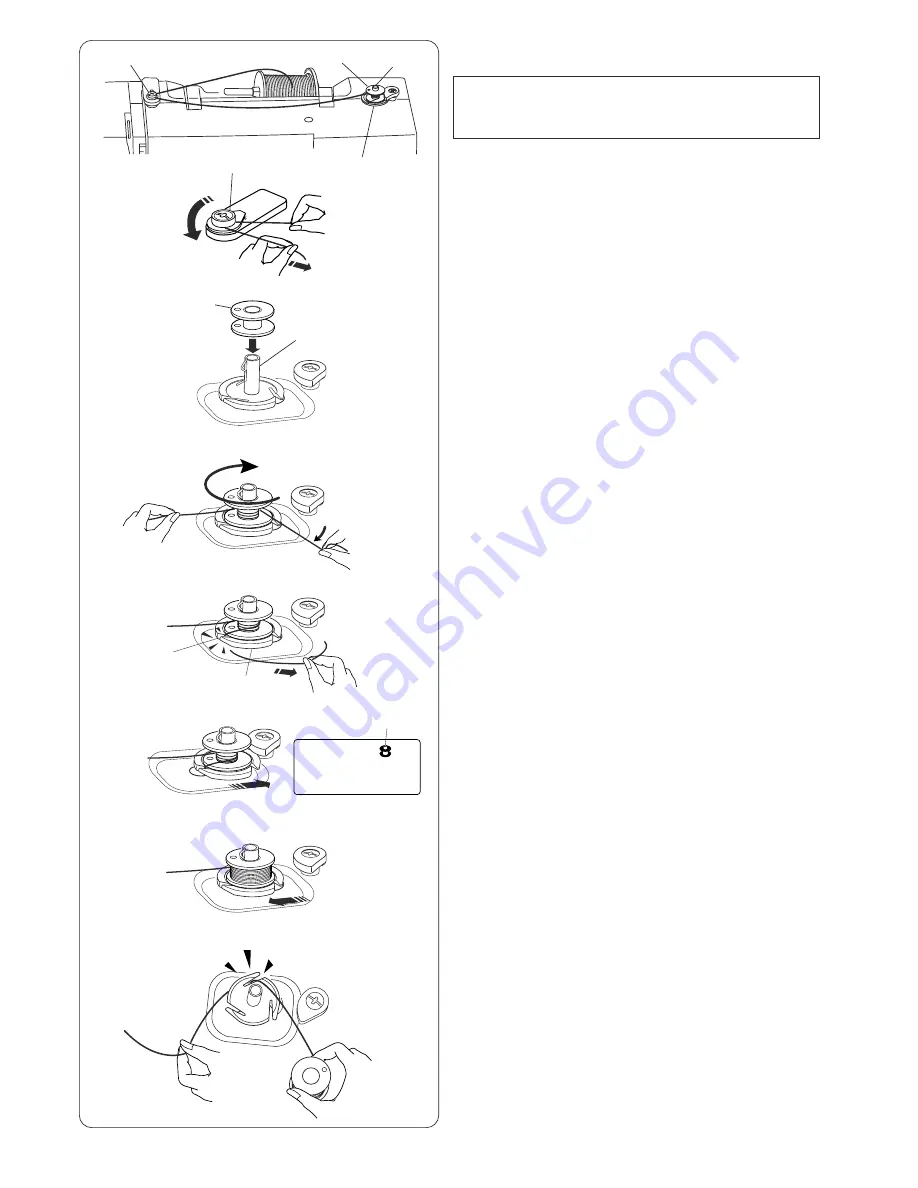

Winding the bobbin

NOTE:

Set the speed control slider at its fastest position for

bobbin winding.

z

Draw the thread from the spool and pass the thread

around the bobbin winding tension disk.

q

Bobbin winding tension disk

x

Put the bobbin on the bobbin winder spindle.

w

Bobbin

e

Bobbin winder spindle

c

Hold the thread with both hands and wind it around

the bobbin clockwise several times.

v

Insert the thread into one of the 3 slits of the flange

plate and pull the thread to cut.

r

Flange plate

t

Slit

b

Push the bobbin to the right. The bobbin icon appears

on the LCD display.

y

Bobbin icon

n

Start the machine. When the bobbin is fully wound, it

will stop spinning automatically.

Stop the machine and return the bobbin winder to its

original position by moving the spindle to the left.

m

Remove the bobbin. Insert the thread into the slit and

pull it to cut as shown.

q

w

e

r

t

y

q

w

e

r

z

x

c

v

b

n

m