18

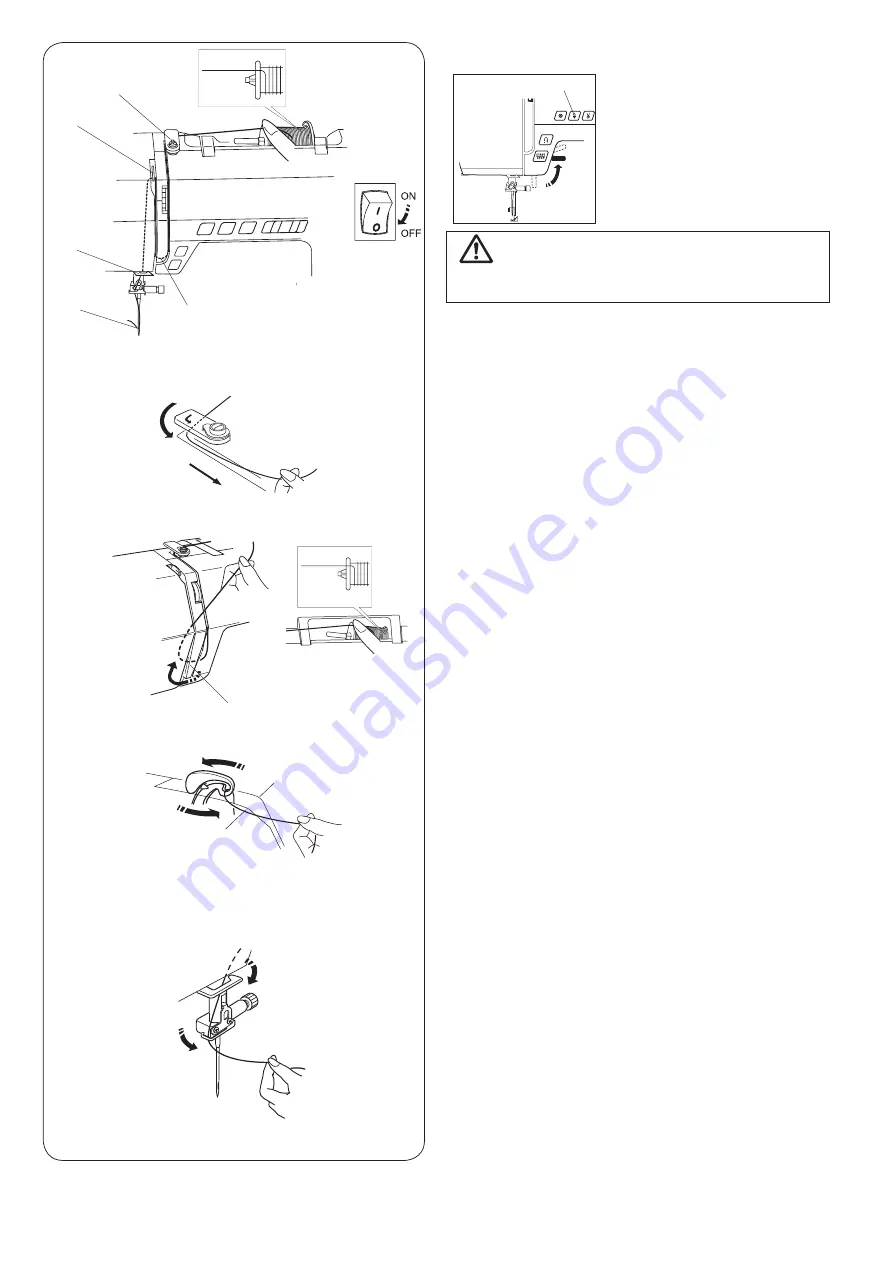

CAUTION:

Turn OFF the power switch before threading the

machine.

z

x

c

v b

w

z

c

v

b

x

z

Turn the power switch off.

Draw the end of the thread around the upper thread

guide.

Threading the Machine

x

While holding the thread near the spool

w

, draw

the end of the thread down around the check spring

holder

e

.

w

Spool

e

Check spring holder

c

Firmly draw the thread up from right to left over the

take-up lever, and down into the take-up lever eye.

v

Pass the thread through the lower thread guide. Slide

the thread behind the needle bar thread guide on the

left.

b

Use the needle threader to thread the needle (see

page 19).

w

Raise the presser foot. Press the

needle up/down button

q

to raise

the thread take-up lever to its

highest position.

q

Needle up/down button

q

e

Summary of Contents for DC6100

Page 1: ...Instruction Book...

Page 2: ......

Page 58: ...56 Stitch Chart...

Page 59: ......

Page 60: ...812 800 032 EN...