6

1

2

3

3

2

6

1

2

3

3

2

1

2

4

1

2

3

3

Ïîäúåì è îïóñêàíèå ïðèæèìíîé ëàïêè

Ðû÷àã ïîäúåìà ïðèæèìíîé ëàïêè ïîäíèìàåò è

îïóñêàåò ïðèæèìíóþ ëàïêó.

Âû ìîæåòå ïîäíÿòü ëàïêó íà 0,6 ñì âûøå

îáû÷íîãî ïîëîæåíèÿ äëÿ áûñòðîé ñìåíû

ïðèæèìíîé ëàïêè èëè äëÿ áåñïðåïÿòñòâåííîãî

ðàçìåùåíèè îáúåìíûõ ìàòåðèàëîâ ïîä ëàïêîé.

1 Îïóùåííîå ïîëîæåíèå

2 Îáû÷íîå ïîäíÿòîå ïîëîæåíèå

3 Íàèâûñøåå ïîëîæåíèå

Ñìåíà ïðèæèìíîé ëàïêè

ÂÍÈÌÀÍÈÅ!

Ïåðåä ñìåíîé ïðèæèìíîé ëàïêè îòêëþ÷èòå

ïèòàíèå.

Âñåãäà èñïîëüçóéòå òîëüêî ïîäõîäÿùóþ ëàïêó

äëÿ âûáðàííîãî îáðàçöà. Èç-çà íåïðàâèëüíîé

ëàïêè ìîæåò ñëîìàòüñÿ èãëà.

Êàê ñíÿòü ïðèæèìíóþ ëàïêó

Ïîâåðíèòå ìàõîâîå êîëåñî ïðîòèâ ÷àñîâîé

ñòðåëêè è ïîäíèìèòå èãëó â âåðõíåå ïîëîæåíèå.

Ïîäíèìèòå ïðèæèìíóþ ëàïêó è íàæìèòå íà

ðû÷àã ïîçàäè äåðæàòåëÿ ëàïêè.

1 Ðû÷àã

Êàê ïðèñòåãíóòü ïðèæèìíóþ ëàïêó

Ðàñïîëîæèòå âûáðàííóþ ïðèæèìíóþ ëàïêó òàê,

÷òîáû ñòåðæåíü íàõîäèëñÿ ïðÿìî ïîä âûåìêîé

äåðæàòåëÿ.

Îïóñòèòå äåðæàòåëü ëàïêè è ïðèñòåãíèòå ëàïêó.

2 Âûåìêà äåðæàòåëÿ

3 Ñòåðæåíü ëàïêè

Êàê ñíÿòü è óñòàíîâèòü äåðæàòåëü ëàïêè

ÂÍÈÌÀÍÈÅ!

Ïåðåä ñìåíîé äåðæàòåëÿ ïðèæèìíîé ëàïêè

îòêëþ÷èòå ïèòàíèå.

×òîáû ñíÿòü:

Ïåðåâåäèòå èãëó â âåðõíþþ ïîçèöèþ.

Ïîâåðíèòå îòâåðòêîé âèíò ïðîòèâ ÷àñîâîé

ñòðåëêè è ñíèìèòå åãî.

×òîáû óñòàíîâèòü:

Ñîïîñòàâüòå îòâåðñòèÿ â äåðæàòåëå ëàïêè ñ

îòâåðñòèåì íà ïðèæèìíîì ñòåðæíå . Âñòàâüòå

âèíò â îòâåðñòèå. Îòâåðòêîé çàòÿíèòå âèíò ïî

÷àñîâîé ñòðåëêå.

1 Óñòàíîâî÷íûé âèíò

2 Äåðæàòåëü ëàïêè

3 Îòâåðñòèÿ â äåðæàòåëå ëàïêè

4 Îòâåðñòèå â ïðèæèìíîì ñòåðæíå

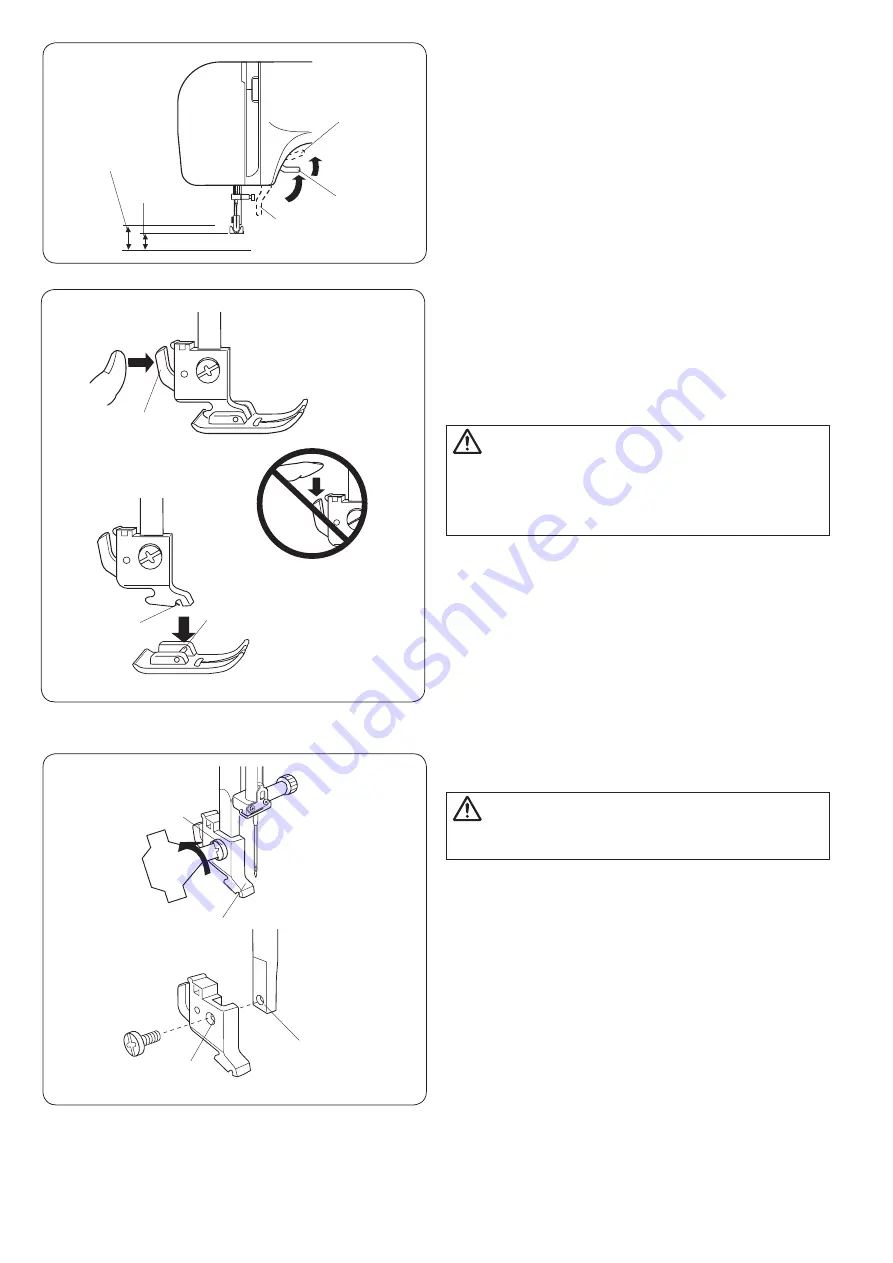

Raising and Lowering the Presser Foot

The presser foot lifter raises and lowers the presser foot.

You can raise the foot about 1/4˝ (0.6 cm) higher than the

normal up position for easy removal of the presser foot,

or to help you place heavy fabric under the foot.

q

Lowered position

w

Normal up position

e

Extra up position

Changing the Presser Foot

To remove:

Raise the needle to its highest position by turning the

handwheel counterclockwise. Raise the presser foot, and

press the lever on the back of the foot holder.

q

Lever

CAUTION:

Turn OFF the power switch before changing the foot.

Always use the proper foot for the selected pattern. The

wrong foot can cause the needle to break. Do not push

the lever down to prevent it from being broken.

To attach:

Place the desired presser foot, so that the pin on the foot

lies just under the groove on the foot holder. Lower the

presser foot lifter to lock the foot in place.

w

Groove

e

Pin

Removing and Attaching the Foot Holder

WARNING:

Turn OFF the power switch before detaching or

attaching the foot holder.

To remove:

Remove the setscrew by turning it counterclockwise with

a screwdriver and remove the foot holder.

To attach:

Match the hole in the foot holder with the threaded hole

in the presser bar. Fit the setscrew into the hole. Tighten

the screw by turning it clockwise with a screwdriver.

q

Setscrew

w

Foot holder

e

Hole

r

Threaded hole

q

w

w

e

e

w

e

q

w

e

r

q