22

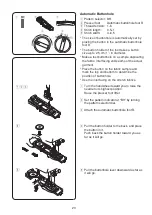

Tape the button over the placement mark.

A pin can be placed on top of the foot to from a

shank.

Before lowering the foot, test the needle swing

making sure the needle drops in each hole.

Adjust the stitch width if necessary.

Lower the foot.

Align the both holes of button with the needle

swing, lower the foot and depress the foot

control.

To strengthen the shank, cut the threads leaving

a 20 cm (8˝) tail.

Bring the needle thread down through the hole

in the button and wind it around the shank.

Draw the thread to the wrong side of fabric and

knot.

* When button sewing is finished, return the

drop feed lever.

w

q

t

r

q

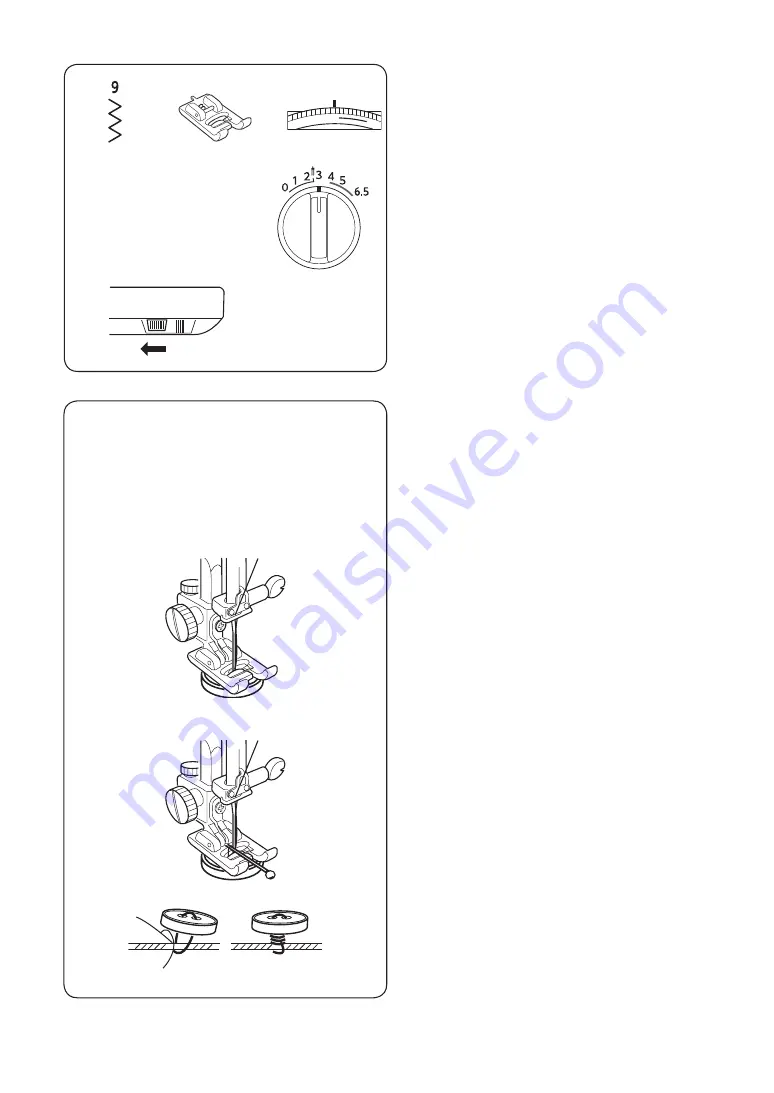

Pattern selector: 9

w

Presser foot: Transparent buttonhole foot B

e

Thread tension: 3–7

r

Stitch width: 3–3.5

t

Feed dog: Lowered

Sewing Buttons

e

4

6

5

Summary of Contents for HD1800

Page 1: ...INSTRUCTION BOOK...

Page 2: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ...753 800 472 EN...