9

z

c

x

z

x

c

v

b

v

b

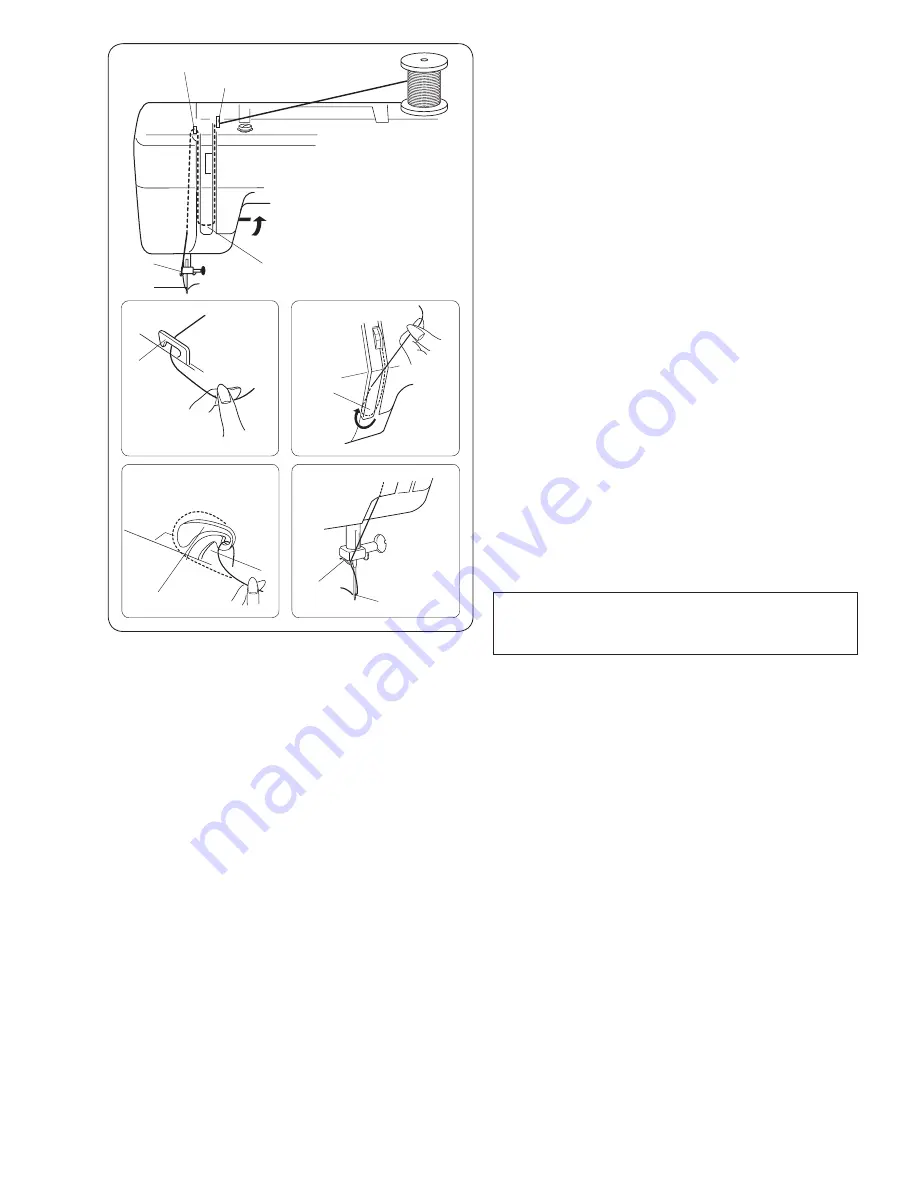

Threading the Machine

Raise the take-up lever to its highest position by

turning the handwheel toward you.

Raise the presser foot.

Place a spool on the spool pin as shown, with

thread coming from back of the spool.

z

Draw the thread into thread guide using both

hands.

x

While holding the thread near spool, draw

thread down into the tension area and then

around the check spring holder.

c

Firmly draw the thread up and through the

take–up lever from right to left.

v

Then draw the thread down and slip it into

needle bar thread guide on the left.

b

Thread the needle eye from front to back.

NOTE: You may want to cut the thread end with

sharp scissors for easier needle

threading.