MECHANICAL ADJUSTMENT

NEEDLE SWING

CORRECT SETTING

IF THE TIMING OF NEEDLE SWING IS NOT CORRECTLY ADJUSTED, THE NEEDLE WILL MOVE

SIDEWISE WHILE IT IS IN THE FABRIC.

IDEALLY THE NEEDLE SHOULD START SWING FROM A POSITION 2 MM - 3 MM ABOVE THE

NEEDLE PLATE IN ITS RIGHT OUTFLOW. (WITH MAXIMUM ZIGZAG WIDTH.)

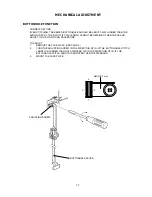

TO ADJUST

1.

SET THE PATTERN SELECTOR DIAL WITH MAXIMUM ZIGZAG WIDTH, AND REMOVE THE

FRONT COVER. (SEE PAGE 5.)

2.

LOOSEN TWO SET SCREWS.

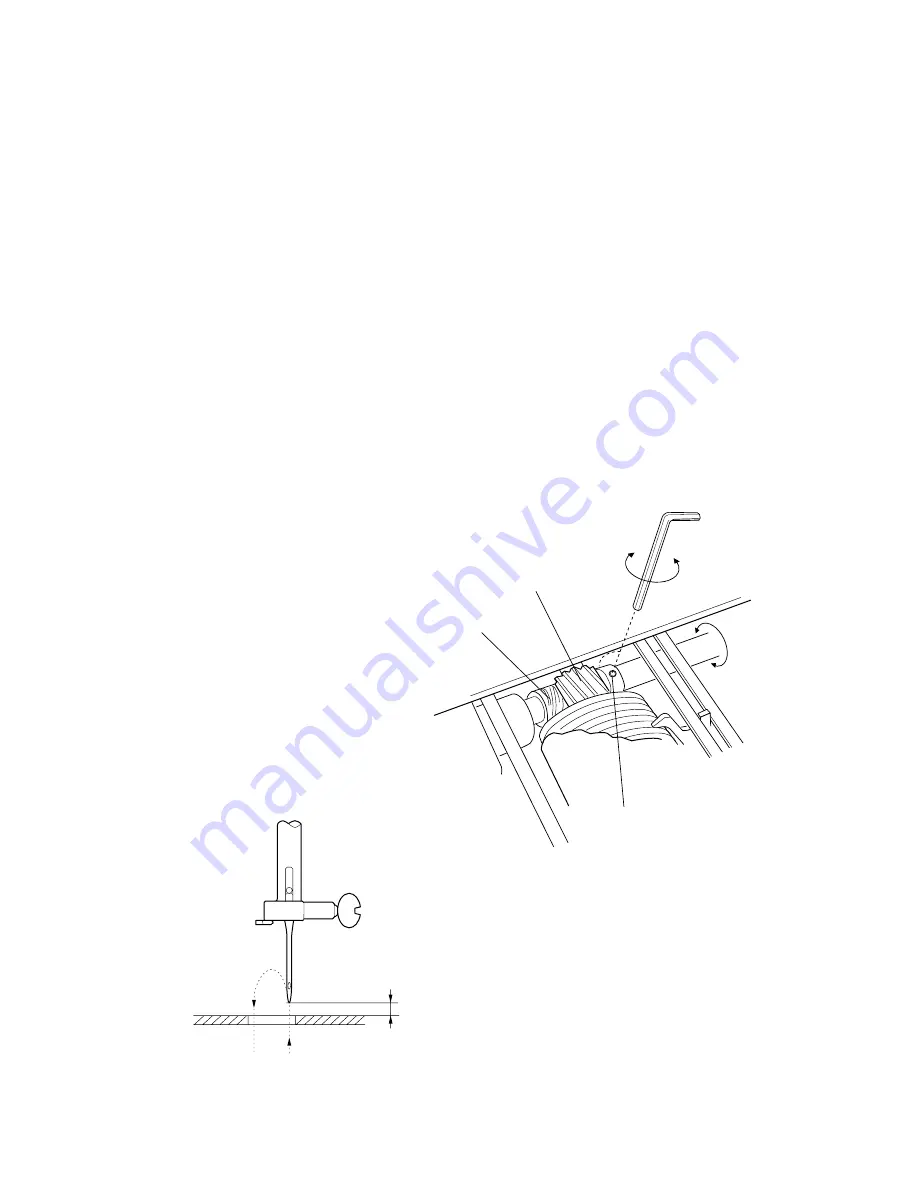

3.

ADJUST THE NEEDLE SWING BY TURNING THE BALANCE WHEEL, WHILE PRESSING THE

WORM SO AS NOT TO ROTATE IT, UNTIL THE NEEDLE SWING STARTS AT 2 MM - 3 MM ON

THE NEEDLE PLATE AFTER THE NEEDLE HAS COME OUT OF THE RIGHT SIDE OF THE

NEEDLE HOLE.

4.

TIGHTEN TWO SET SCREWS.

5.

MOUNT THE FRONT COVER.

NOTE:

AFTER ADJUSTING THE NEEDLE SWING, CHECK THAT THE UPPER SHAFT WORM AND

GEAR ROTATE SMOOTHLY ANY BACKLASH BETWEEN THEM.

SET SCREW (2 PCS.)

GEAR

UPPER SHAFT WORM

2 - 3 mm

10