16

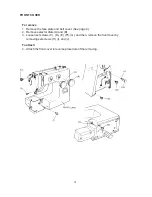

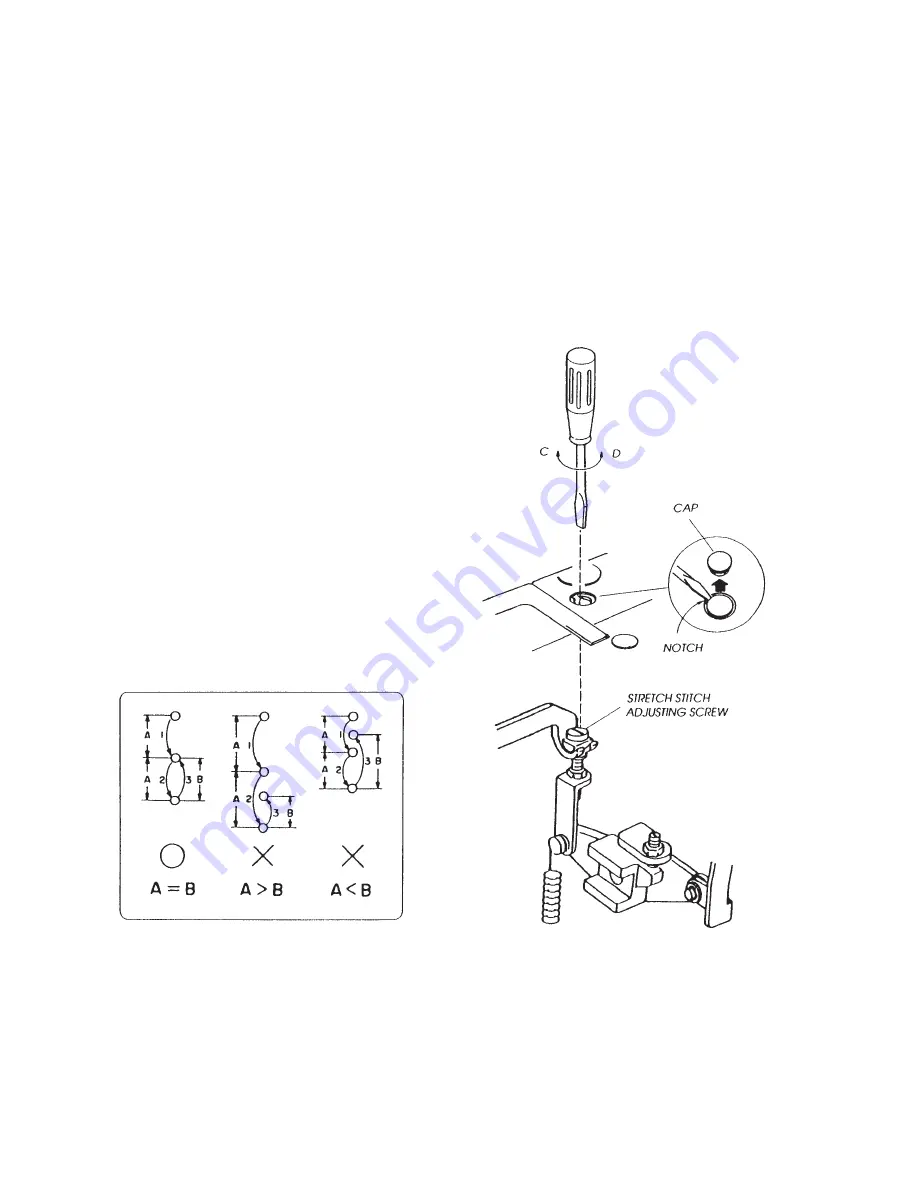

FEED BALANCE ON STRETCH STITCH

Correct setting

If the stretch stitches are distorted, adjust it as follows:

To adjust

1.

Remove the cap.

2.

Set the pattern selector dial at” A “, and the stitch length dial at “SS”.

3.

Turn the stretch stitch adjusting screw in the direction of “C” when A> B, or in the

direction of “D” when A < B.

4.

Attach the cap.

Summary of Contents for JF1018S

Page 1: ...SERVICING MANUAL Model JF1018S...

Page 24: ...22 WIRING...