3

q

w

e

r

t

y

u

i

o

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

@0

@1

@2

@3

@4

@5

@6

@7

@8

@9

#0

#1

#2

#3

#4

#5

#6

#7

#8

#9

$0

$1

$2

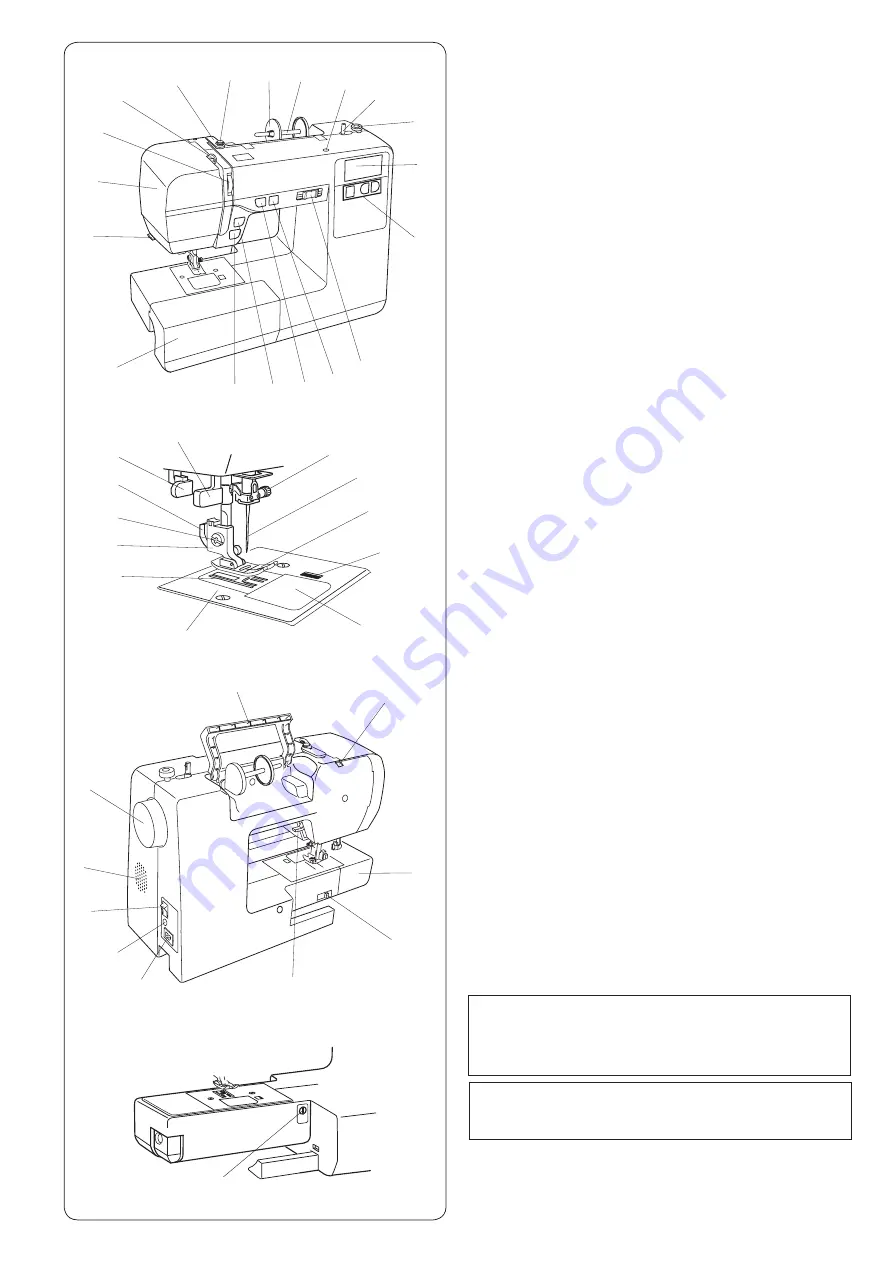

NAMES OF PARTS

Names of Parts

$2

NOTE:

Design and specifications are subject to change

without prior notice.

Upper thread guide

Bobbin winding tension disk

Spool holder (large)

Spool pin

Hole for extra spool pin

Bobbin winder spindle

Bobbin winder stopper

LCD display

Function keys

Speed control slider

Needle up/down button

Auto-lock button

Reverse button

Start/stop button

Extension table (Accessory box)

Thread cutter

Face cover

Thread tension dial

Thread take-up lever

Needle clamp screw

Needle

Presser foot

Hook cover release button

Hook cover plate

Needle plate

Feed dogs

Foot holder

Setscrew

Lever

Buttonhole lever

Needle threader

Carrying handle

Hole for stitch chart

Free-arm

Drop feed lever

Presser foot lifter

Power inlet

Foot control jack

Power switch

Ventilation openings

Handwheel

Feed balancing dial

q

w

e

r

t

y

u

i

o

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

@0

@1

@2

@3

@5

@6

@7

@8

@9

#2

#4

#5

#6

#7

#8

#9

$0

$1

NOTE:

To carry the sewing machine, hold the carrying handle

with your hand, and support the sewing machine with

the other hand.

@4

#0

#1

#3

Summary of Contents for JW8100

Page 1: ...Instruction Book...

Page 2: ......

Page 56: ...54 Stitch Chart...

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ...811 800 202 ENG...