34

Condition

Cause

Reference

The needle breaks.

Skipped stitches

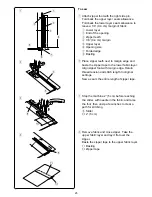

Seam puckering

The cloth is not fed

smoothly.

The needle thread

breaks.

The bobbin thread

breaks.

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is incorrectly inserted.

5. The needle thread and the bobbin thread are not drawn to

the rear and set properly under the presser foot when

starting sewing.

6. The fabric is not drawn to the rear when sewing is finished.

7. The thread is too heavy or too fine for the needle.

1. The bobbin thread is not threaded properly in the bobbin

holder.

2. Lint has collected in the bobbin holder.

3. The bobbin is damaged and does not turn smoothly.

4. The thread is wound loosely on the bobbin.

1. Needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle clamp screw is loose.

4. A proper foot is not used.

5. The fabric is not drawn to the rear when sewing is finished.

6. The needle is too fine for the fabric being sewn.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle and/or thread are not suitable for the fabric

being sewn.

4. A blue tip needle is not used for sewing stretch, very fine

fabrics and synthetics.

5. The needle thread is not threaded properly.

6. A poor quality needle is used.

1. The needle thread tension is too tight.

2. The needle thread is not threaded properly.

3. The needle is too heavy for the fabric being sewn.

4. The stitch length is too long for the fabric.

* Use a stabilizer for very fine fabrics.

1. The feed dog is packed with lint.

2. The stitches are too fine.

3. The feed dog was not raised after being lowered.

4. The foot pressure is not adjusted properly.

Page 11

Page 15

Page 7

Page 7

Page 16

Page 16

Page 7

Page 10

Page 32

Replace the bobbin

Re-wind the bobbin.

Page 7

Page 7

Page 7

Use proper foot.

Page 16

Page 7

Page 7

Page 7

Page 7

Page 7

Page 11

Replace the needle

Page15

Page 11

Page 7

Make stitch shorter

Page 32

Make stitch longer

Page 5

Page 5

The buttonhole is

not sewn well.

The machine does

not work.

Patterns are distorted.

1. The machine is not plugged in.

2. Thread is caught in the hook race.

3. The handwheel is pulled for bobbin winding.

1. The stitch is not balanced.

1. The stitch density is not suitable for the fabric being sewn.

2. Interfacing is not being used with stretch fabrics.

Page 4

Page 32

Page 9

Page 14

Page 22

Page Use interfacing

Troubleshooting

The needle thread

loops.

1. The needle thread tension is too loose.

2. The needle size is not suitable for the thread.

Page 15

Page 7

Noisy operation

1. The feed dog is packed with lint.

2. Lint has collected in the bobbin holder.

Page 32

Page 32

Summary of Contents for Magnolia 7318

Page 1: ...INSTRUCTION MANUAL...