AAASewing.com

25

W: 00

W: 01

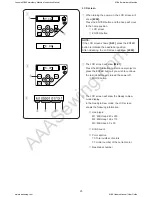

LCD screen

z

When turning the power on, the LCD screen will

show [W:00].

Press the ENTER button and the hoop will move

to the home position.

q

LCD screen

w

ENTER button

NOTE:

If the LCD screen shows [E:03], press the ENTER

button to initialize the needle bar position.

After initializing, the LCD screen will show [W:00].

x

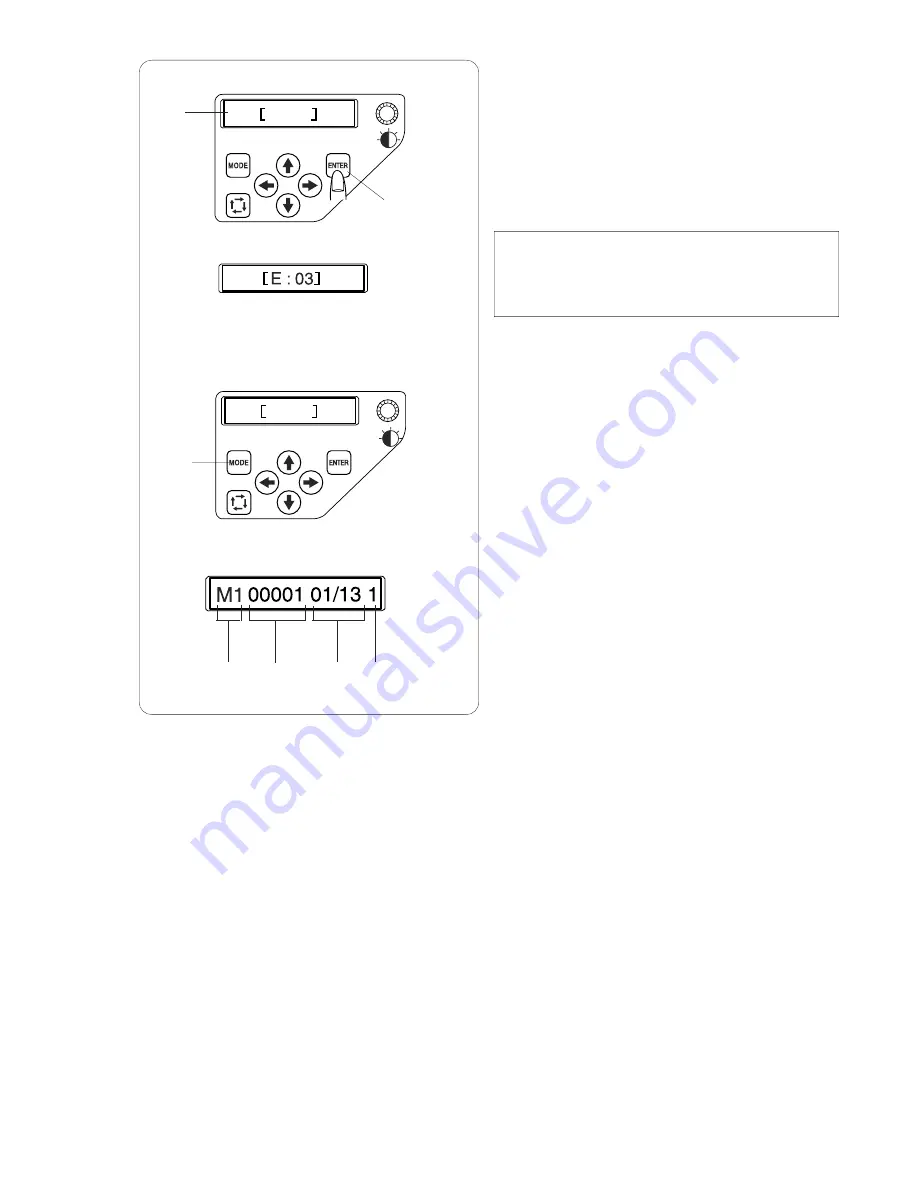

The LCD screen will show [W:01].

Press the MODE button to start a new project or

press the ENTER button if you wish to continue

the last job before you turned the power off.

e

MODE button

c

The LCD screen will show the Ready to Sew

mode display.

In the Ready to Sew mode, the LCD screen

shows the following information.

r

Hoop type

M1: MB Hoop 240 x 200

M2: MB Hoop 126 x 110

M3: MB Hoop 50 x 50

t

Stitch count

y

Color section

13: Total number of colors

01: Order number of the current color

u

Needle bar number

y

u

q

w

e

r

t

z

x

c

Janome MB4 Embroidery Machine Instruction Manual

MB-4 Embroidery Machine

www.aaasewing.com

MB4 Owners Manual/ User Guide