24

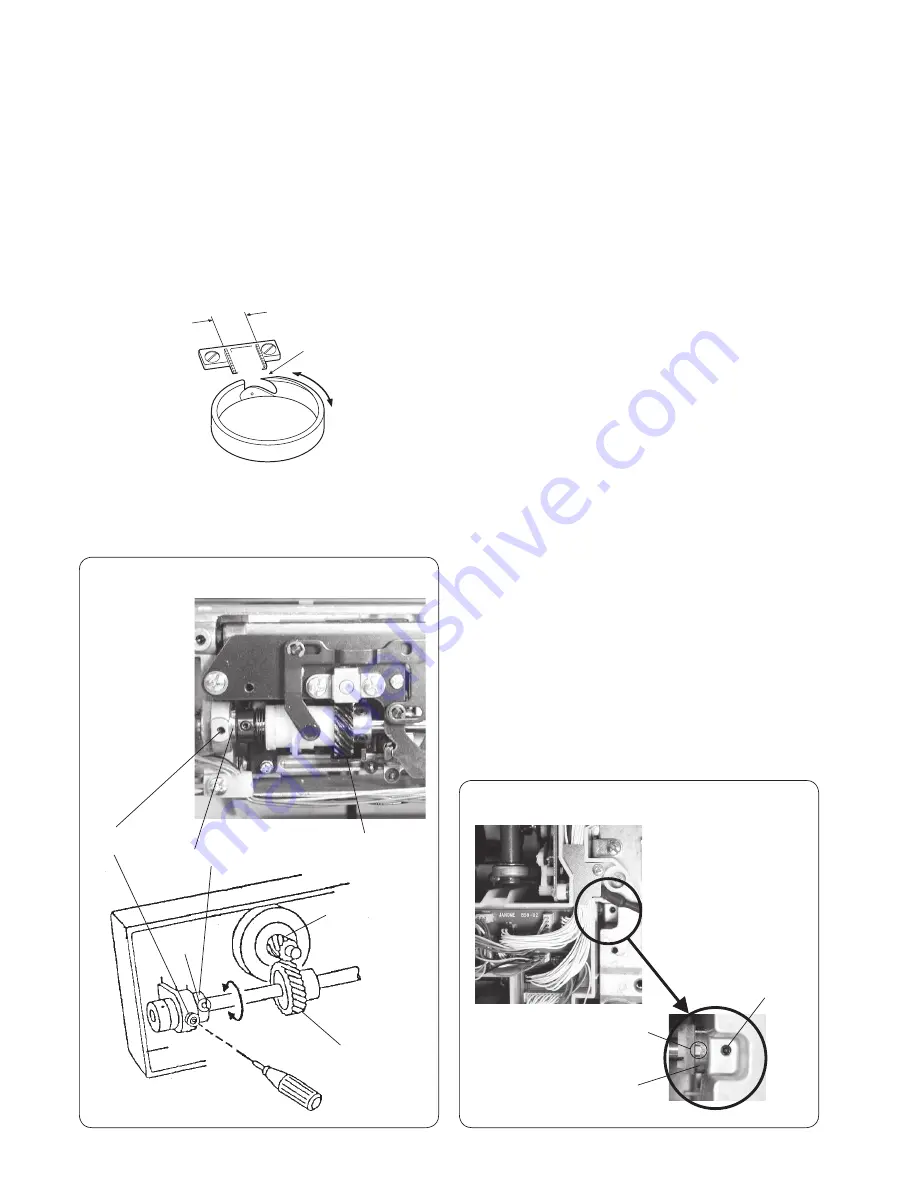

A

B

Lower shaft bushing

Hexagonal socket

screw (C)

Lower shaft gear

Hook driving gear

Lower shaft gear

Lower bushing of the front side

Lower bushing of the belt cover

Lower shaft bushing

Hexago-

nal socket

screw (D)

Mechanical adjustment

Backlash between hook drive gear and lower shaft gear

The rotary play of the hook should be 0.8 mm or less when the tip of rotary hook is within the width of feed dog.

Tip of rotary hook

1. Remove the base cover and bed cover (see page 2 and 3).

2. Remove the presser foot, the needle plate and the bobbin

holder. (see page 4)

* Cover the needle plate with the fabric to prevent

damaging the needle plate when removing.

3. Turn the handwheel toward you so the the tip of the rotary

hook is within the width of feed dog as shown in figure 1.

Check the rotary play of the hook.

4. If the backlash is too much or too little, loosen the hexagonal

socket screw (C) and (D) and following the adjustment

procedure.

If the backlash is too great (more than 0.8 mm), turn the

lower shaft bushings in direction A. If the engagement of

gear is too tight, and the machine does not turn smoothly, )

turn the lower shaft bushings in direction B.

Adjust the grooves of the lower shaft bushing as well.

5. Tighten the hexagonal socket screws.

Width of feed dog

groove

groove