29

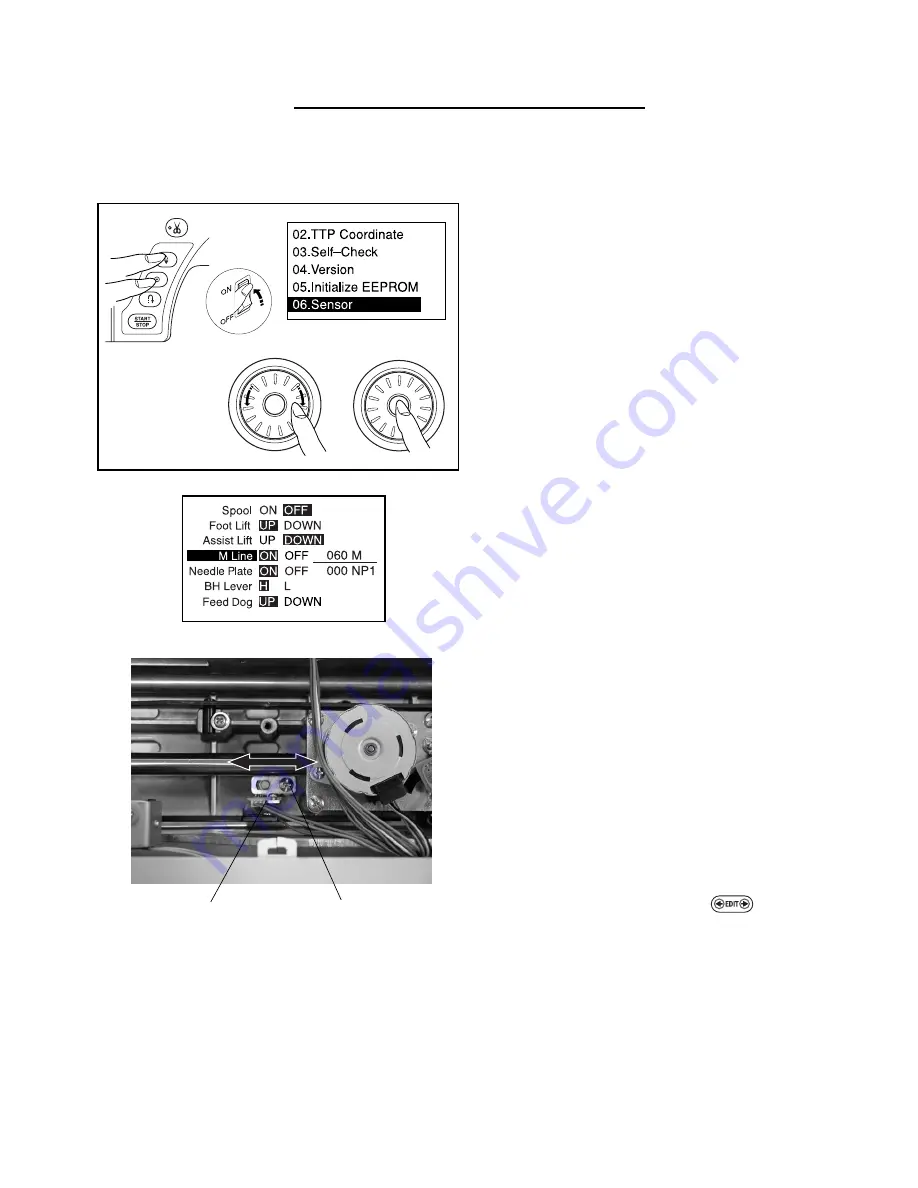

[TO CHECK]

1. WHILE PRESSING THE NEEDLE UP/DOWN AND

LOCK STITCH BUTTONS, TURN THE POWER

SWITCH ON. THE LCD SCREEN WILL DISPLAY

“FACTORY ADJUST”.

2. TURN THE JOG DIAL TO SELECT “06. Sensor”.

PRESS THE CONFIRM BUTTON.

3. TURN THE JOG DIAL TO SELECT “M Line”.

PRESS THE CONFIRM BUTTON.

THE NEEDLE POSITION WILL BE INITIALIZED.

4. THE NEEDLE BAR IS AT CENTER NEEDLE

POSITION (060).

BE SURE THAT “M Line” SIGNAL SHOULD BE “ON”

(FIG.1).

IF NOT, ADJUST THE CENTER NEEDLE POSITION

SENSOR AS FOLLOWS.

[ADJUSTMENT]

5. OPEN THE FACE PLATE.

REMOVE THE TOP COVER (SEE PAGE 1).

6. BE SURE THAT THE NEEDLE BAR IS AT

“060” POSITION (CENTER NEEDLE POSITION).

LOOSEN THE SETSCREW.

ADJUST THE SENSOR POSITION BY MOVING THE

SENSOR PLATE IN THE DIRECTION OF ARROWS

SO THAT THE “M Line” SENSOR SHOULD BE “ON”

WHEN THE NEEDLE BAR IS AT “060” POSITION.

TIGHTEN THE SETSCREW.

* BE CAREFUL NOT TO TOUCH THE SENSOR

BOARD WITH A SCREWDRIVER WHILE THIS

ADJUSTMENT.

WHEN THE NEEDLE BAR SUPPORTER IS PUSHED

RIGHT AND LEFT VERY LIGHTLY WITHIN THE

RANGE OF PLAY. BE SURE THAT THE “M Line”

SENSOR WILL NOT BE TURNED “OFF”.

7. PRESS THE RIGHT ARROW OF BUTTON.

BE SURE THAT THE “M Line” SENSOR IS “OFF”

WHEN THE NEEDLE BAR IS AT “044” (LEFT) AND

“076” (RIGHT) POSITION. IF NOT, LOOSEN THE

SETSCREW AND ADJUST THE SENSOR POSITION

AGAIN.

8. ATTACH THE TOP COVER.

TURN OFF THE POWER SWITCH.

9. CLOSE THE FACE PLATE.

MECHANICAL ADJUSTMENT

FIG.1

SETSCREW

SENSOR

BOARD

CENTER NEEDLE POSITION SENSOR ADJUSTMENT

THE CENTER NEEDLE POSITION SENSOR WILL BE “ON” WHEN THE NEEDLE BAR IS AT CENTERED POSITION

(INITIALIZED).