q

w

e

r

t

y

u

i

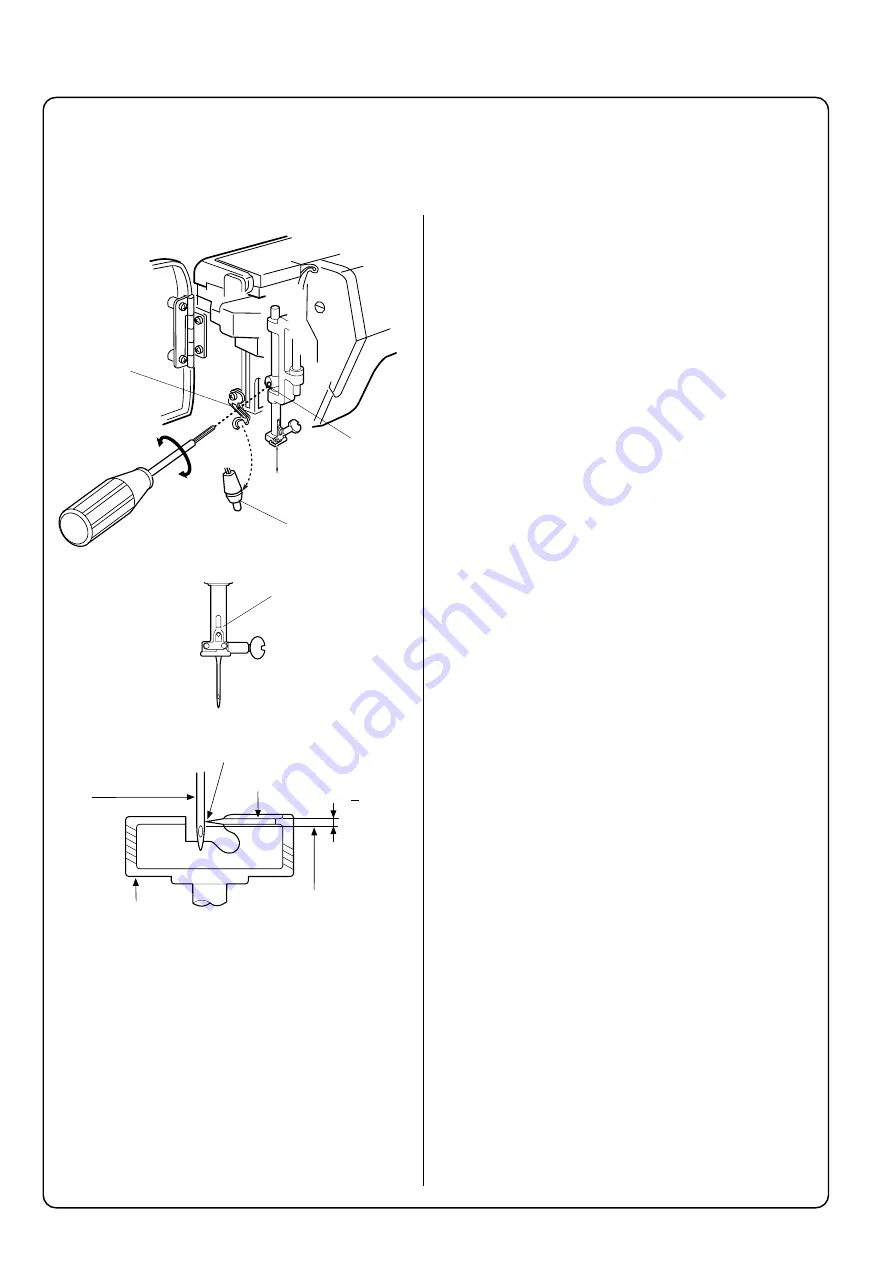

1.8 mm + 0.2

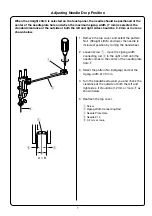

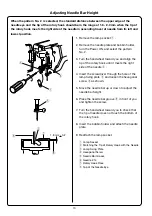

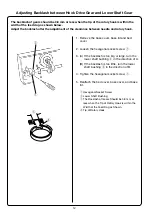

Adjusting Needle Bar Height

When the pattern No. 2 is selected, the standard distance between the upper edge of the

needle eye and the tip of the rotary hook should be in the range of 1.6 - 2.0 mm when the tip of

the rotary hook meets the right side of the needle in ascending travel of needle from its left and

lowest position.

1. Remove the lamp socket

q

.

2. Remove the needle plate and bobbin holder,

turn the Power ON, and select the pattern

No. 2.

3. Turn the handwheel toward you and align the

tip of the rotary hook until it meets the right

side of the needle

w

.

4. Insert the screwdriver through the hole of the

lamp fixing plate

e

and loosen the hexagonal

screw

r

as shown.

5. Move the needle bar up or down to adjust the

needle bar height.

6. Place the needle bar groove

t

in front of you

and tighten the screw.

7. Turn the handwheel toward you to check that

the tip of needle does not touch the bottom of

the rotary hook.

8. Insert the bobbin holder and attach the needle

plate.

9. Reattach the lamp socket.

q

Lamp Socket

w

Matching the Tip of Rotary Hook with the Needle

e

Lamp Fixing Plate

r

Hexagonal Screw

t

Needle Bar Groove

y

Needle # 14

u

Rotary Hook Race

i

Top of the Needle Eye

10

Summary of Contents for Memory Craft 10001

Page 1: ...SERVICING MANUAL...

Page 42: ...40...