28

Zipper Sewing

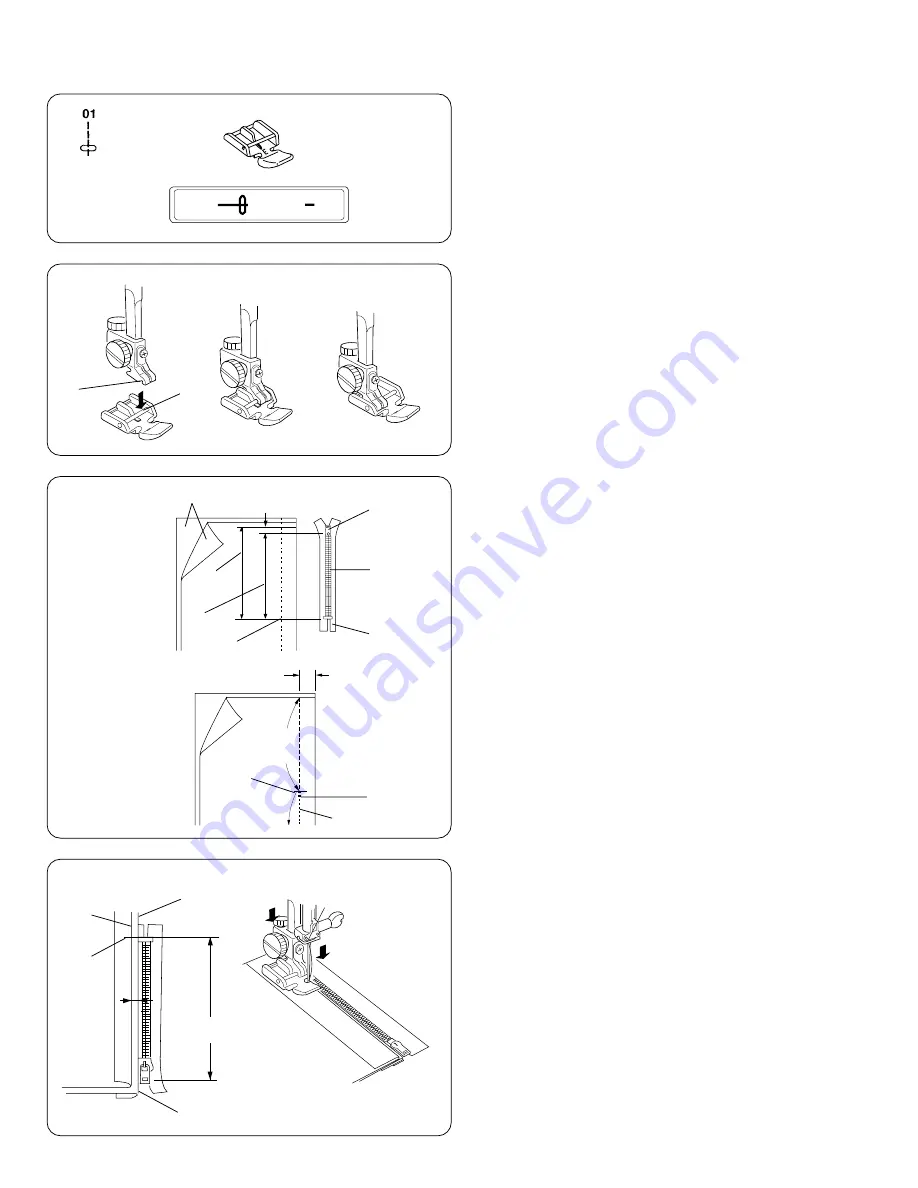

Choose Stitch Pattern 01 and attach Foot E.

q

Selected stitch

w

E: Zipper foot

• To Snap On the Zipper Foot

Fit the pin on the zipper foot into the groove on the foot

holder.

*

To sew the left side of the zipper, attach the zipper

foot on the right-hand side.

*

To sew the right side of the zipper, attach the

zipper foot on the left-hand side.

q

Groove

w

Pin

e

When the left side is sewn.

r

When the right side is sewn.

• Fabric Preparation

Add 1 cm (1/2

"

) to the zipper size. This is the overall

opening size.

q

Right side of fabric

w

Opening size

e

Zipper size

r

1 cm(1/2

"

)

t

End of opening

y

Slider

u

Zipper teeth

i

Zipper tape

Place right sides of fabric together and sew to the end of

the zipper opening. Reverse stitch to lock the stitches.

Manually increase the stitch length to 4.5 and sew the

zipper opening.

o

4.5(stitch length)

!0

End of opening

!1

Reverse stitch

!2

Straight stitch

!3

2 cm (3/4

"

)

• To Sew

z

Fold back the left seam allowance. Turn under the

right seam allowance to form a 0.2 to 0.3 cm (1/8")

fold. Place the zipper teeth next to this fold and pin in

place.

Attach the zipper foot with the pin on the right

-

hand

side.

Lower the zipper foot on the top side at the bottom of

the zipper so that the needle pierces the fabric next to

the fold and the zipper tape.

q

Fold

w

0.3 cm (1/8

"

)

e

Stitch line

r

End of opening

t

Opening size

y

Lower fabric

u

Wrong side of fabric

w

q

w

e

r

q

w

e

r

t

y

u

i

o

!0

!1

!2

!3

q

w

r

e

t

y

u

z

q

01

A 2 6

Summary of Contents for memory craft 2400

Page 1: ...2400 INSTRUCTION BOOK...