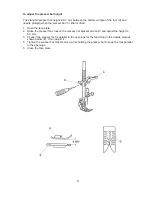

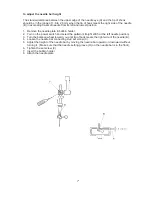

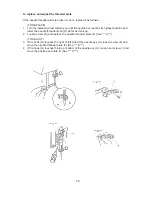

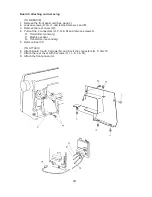

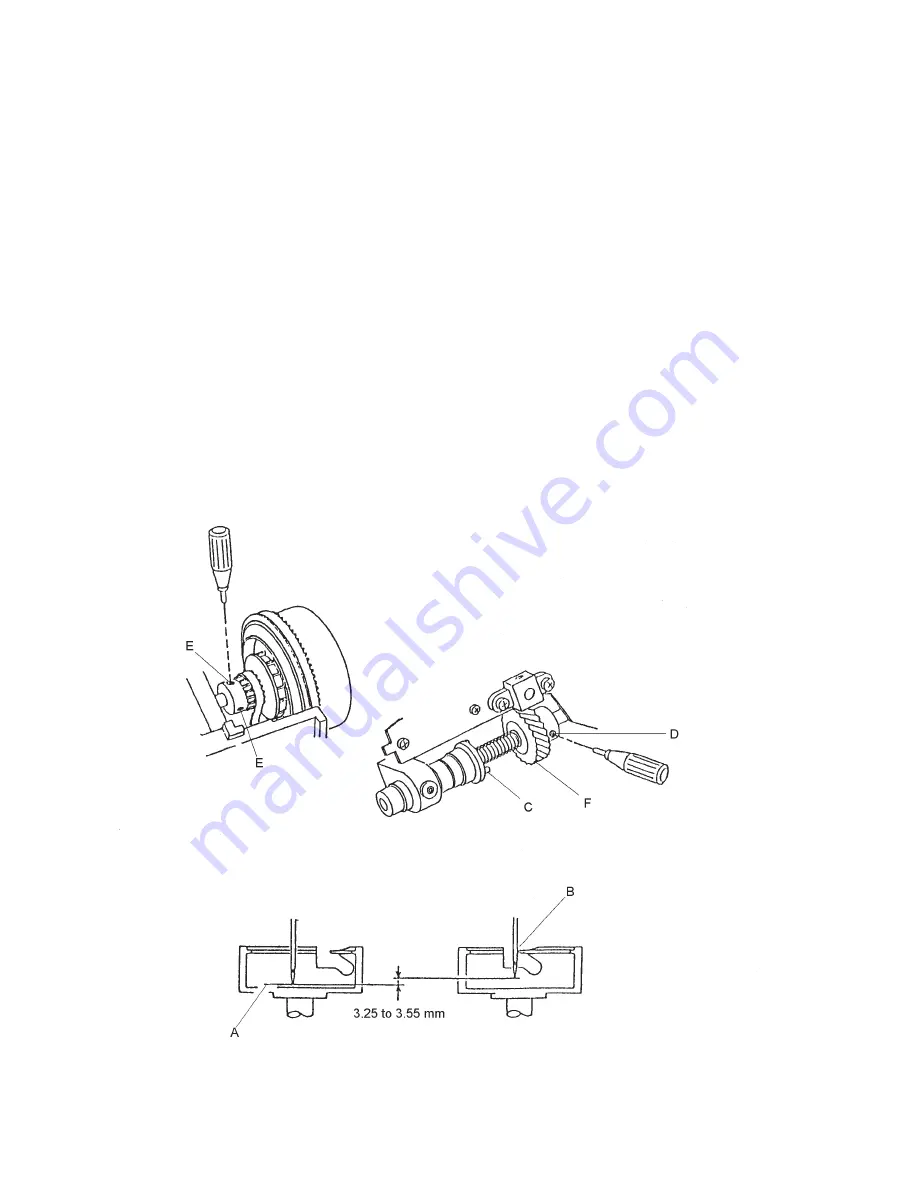

To adjust the hook timing

When the straight stitch at left needle position is selected, the amount of ascending travel of

the needle bar from its lowest position (A) to the position where the tip of the rotary hook ex-

actly meets the right side of the needle (B) should be 3.25 to 3.55 mm.

1. Remove the needle plate and bobbin holder.

2. Turn on the power switch and select the straight stitch at left needle position.

3. Remove the top cover, belt cover and bed cover (See pages 1, 2 and 3).

4. Turn the balance wheel toward you, and set the needle bar to the lowest position (A).

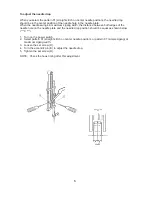

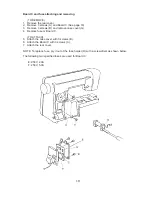

5. In this condition

*

If the projection of feed lifting cam (C) is in the lowest position, loosen the set screws

(D) of lower shaft timing wheel.

*

If not, loosen the set screws (E) of upper shaft toothed wheel.

6. Raise the needle bar further 3.25 to 3.55 mm from the lowest position.

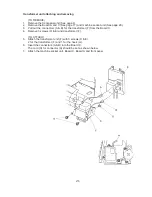

7. Turn the lower shaft gear (F) until the tip of hook meets with the right side of needle (B).

8. Tighten the set screws (D) of lower shaft timing wheel or the ones (E) of the upper shaft

toothed wheel.

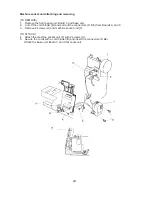

9. Attach the bed cover, belt cover, top cover, bobbin holder and the needle plate.

8

Summary of Contents for Memory Craft 3000

Page 1: ...SERVICE MANUAL...