AAASewing.com

37

PATCHWORK AND QUILTING (Mode 2)

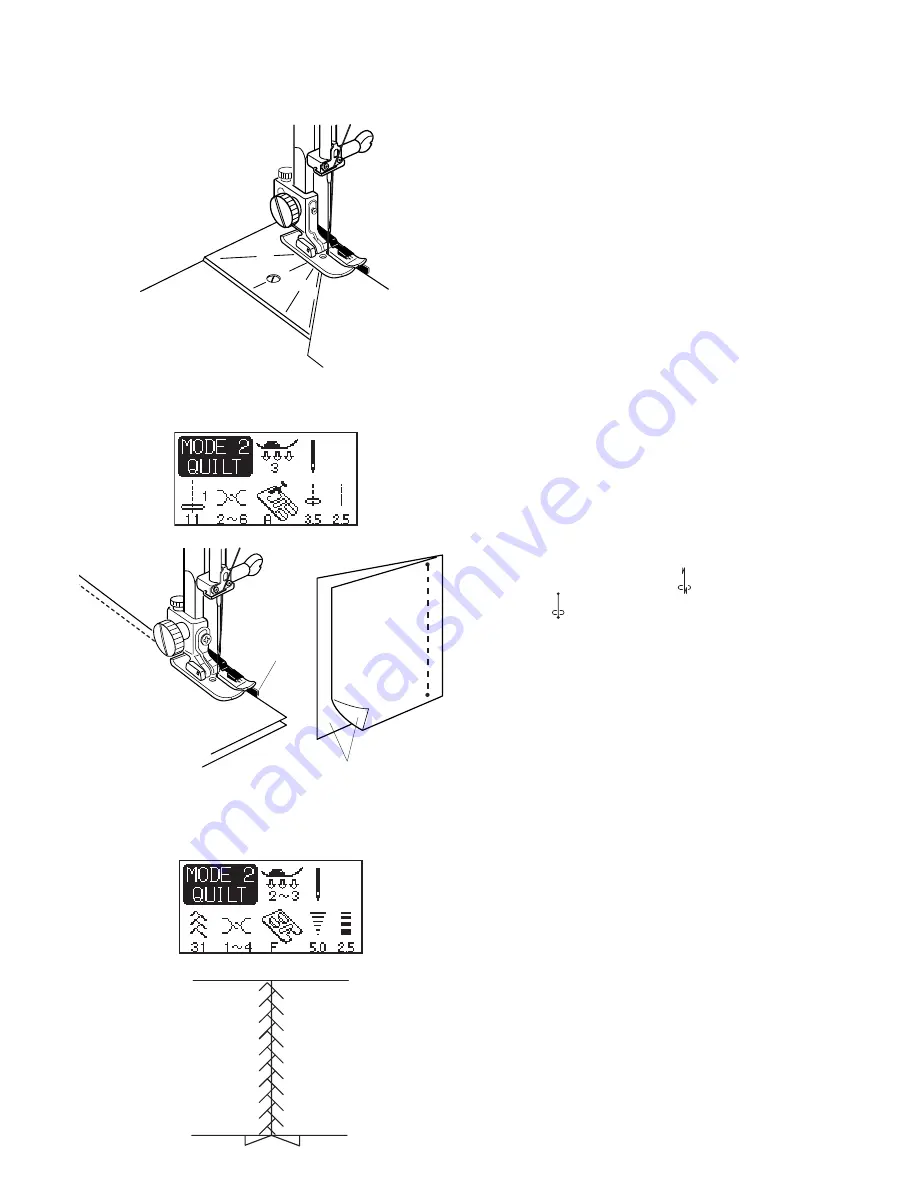

Patchwork

Angle scale on the needle plate

You can easily seam patchwork pieces at the desired

angles without marking, by using the unique angle scales

on the needle plate.

The angle scales are marked at 45, 60, 90 and 120

degrees.

Seaming patchwork pieces

Machine Setting

Pattern:

11 (Mode 2)

Thread tension:2-6

Presser foot:

1/4” Seam foot O

Foot pressure: 3

Lock-a-Matic stitch (pattern 03) and auto lock stitch

(pattern 04) in the Mode 1 are ideal for seaming

patchwork pieces together.

Place the patchwork pieces right sides together. Sew while

guiding the edge of the fabric along the guide on the foot

to keep a precise 1/4” seam allowance.

1

Guide

2

Right Sides of the Fabric

Patchwork stitches

Machine Setting

Pattern:

See below.

Thread tension:1-4

Presser foot:

Satin stitch foot F

Foot pressure: 2-3

The patterns 28-32, 38-42 and 61-68 in the Mode 2 can be

used as patchwork stitches.

Open seam flat with the right side up and sew patchwork

stitch along the seam line.

90

60

45

120

1

2

Janome Memory Craft 6500 Instruction Manual

Janome Sewing Machine

www.aaasewing.com

MC6500P Owners Manual/ User Guide