8

MO200

5200QDC

MECHANICAL ADJUSTMENT

NEEDLE DROP POSITION

Set the stitch pattern at " "; the standard needle drop position should be at the center of the needle

plate hole.

When the needle swings in maximum zigzag width " ", the distance between both ends of the needle

hole in the needle plate and the needle should be 0.2 mm or more. If not, adjust as follows.

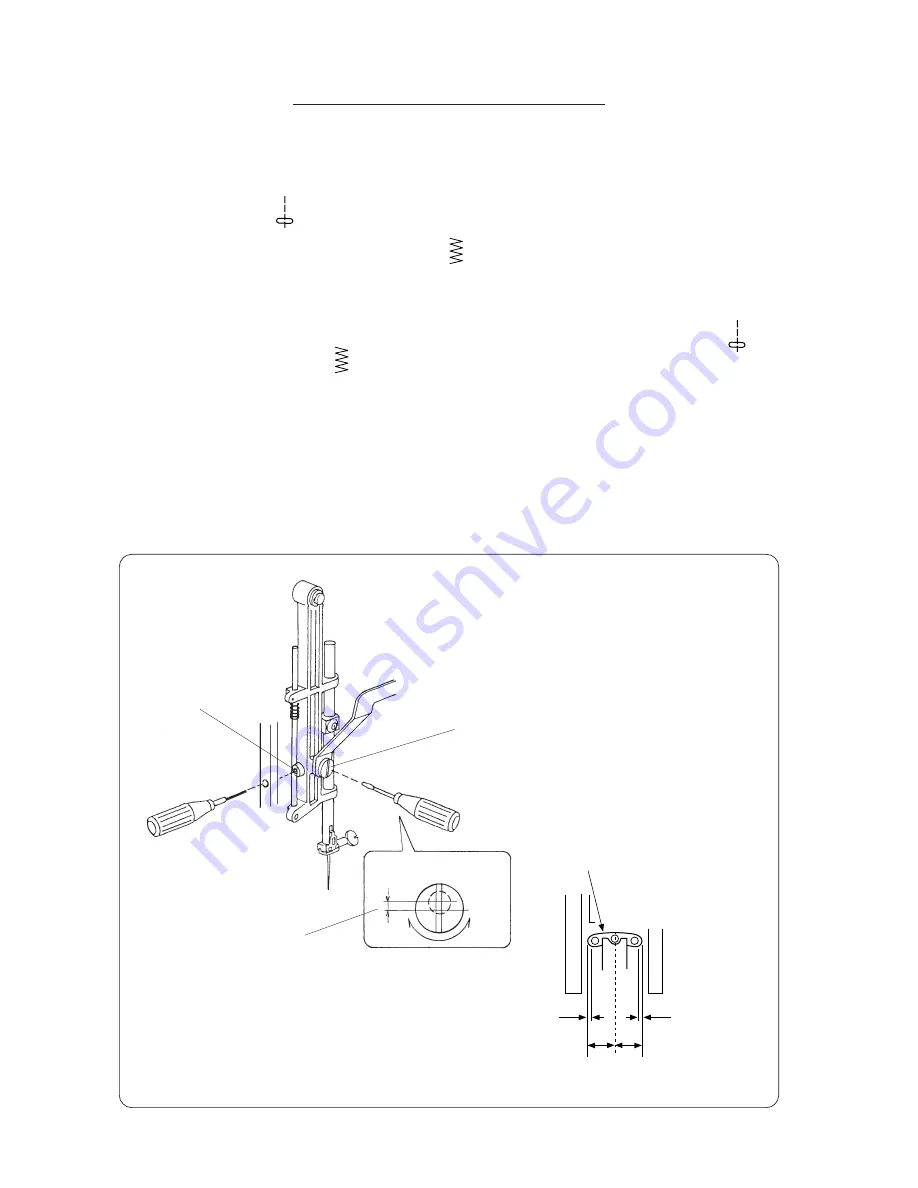

ADJUSTMENT PROCEDURE:

1. Turn on the power switch, check the needle drop position by setting the stitch pattern at straight " " and

the zigzag width at maximum " ".

2. If the needle drop position is not in the center of the needle plate hole when the straight stitch is selected,

or if the clearance between the needle and edge of the needle plate hole on both side is less than 0.2 mm

when the stitch pattern is set to maximum zigzag width, open the face cover and loosen the setscrew (A),

then adjust the needle drop position by turning the eccentric pin.

NOTE:

Make sure the eccentric pin is positioned with its off-center head facing downward.

3. When you have finished adjusting the needle drop position, tighten the setscrew.

Eccentric pin

Setscrew (A)

Needle plate hole

0.2 mm or more

0.2 mm or more

A=B

Eccentric pin position

(Off -center head)

Adjust the needle drop position by turning the

eccentric pin as shown