37

MS5027PR

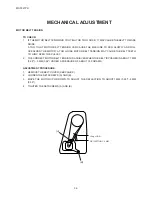

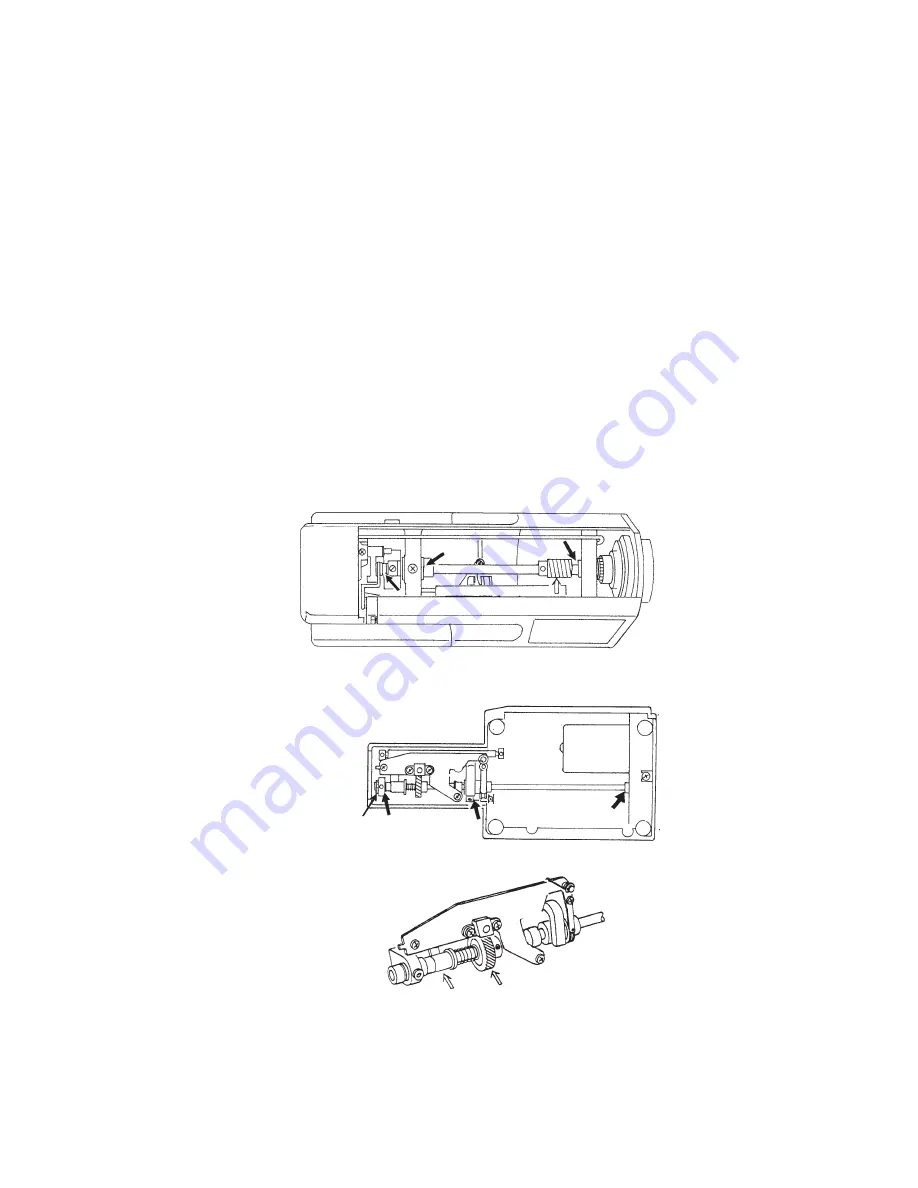

OILING

FACTORY LUBRICATED PARTS WILL PROVIDE YEARS OF HOUSEHOLD SEWING WITHOUT ROUTINE

OILING, BUT YOU SHOULD STILL CHECK FOR POSSIBLE LUBRICATION NEEDS WHENEVER SERVICING

THE MACHINES.

OIL:

USE GOOD QUALITY SEWING MACHINE OIL AT THE POINTS (A, B, C, D, E, F & G) INDICATED BY

THE BLACK ARROWS.

GREASE:

USE WHITE GREASE SUCH AS MOLYCOTE EM-40M AT THE POINTS (H, I, & J) INDICATED BY THE

WHITE ARROWS.

A

B

C

D

E

F

G

H

I

J