11

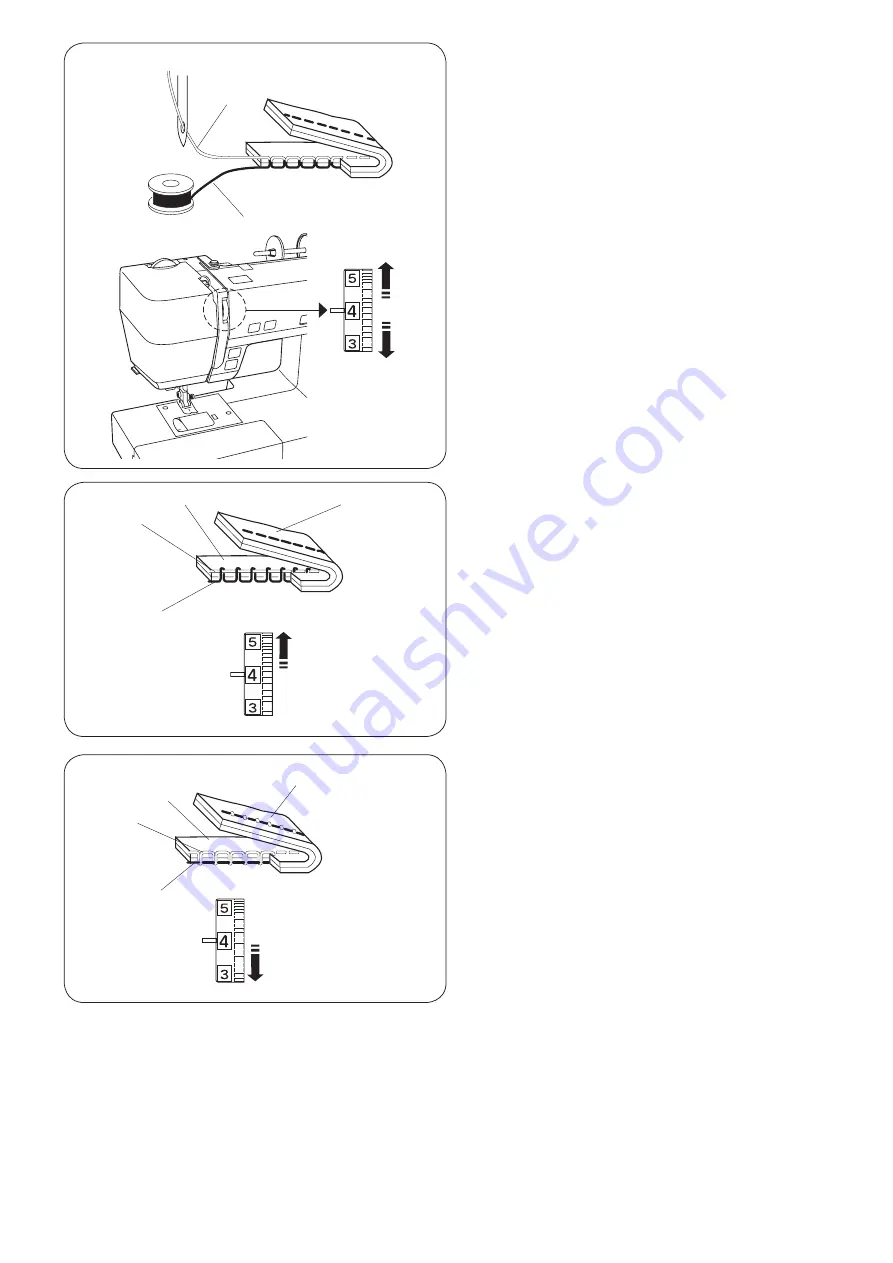

Adjusting the Needle Thread Tension

Straight stitch

balanced tension

The ideal straight stitch has threads locked between two

layers of fabric, as illustrated (magnified to show detail).

If you look at the top and bottom of the seam, notice that

the stitches are evenly balanced.

q

Needle thread (top thread)

w

Bobbin thread (bottom thread)

e

To loosen

r

To tighten

When adjusting the needle thread tension, the higher the

number, the tighter the top thread tension.

Results depend on:

- stiffness and thickness of the fabric

- number of fabric layers

- type of stitch

q

w

e

r

r

q

w

t

e

Tension is too loose

The needle thread shows through on the wrong side of

the fabric, and the stitch feels bumpy. Turn the dial to a

higher number to tighten the needle thread tension.

q

Needle thread (top thread)

w

Bobbin thread (bottom thread)

e

To tighten tension

r

Right side (top side) of fabric

t

Wrong side (bottom side) of fabric

r

q

w

t

e

Tension is too tight

The bobbin thread shows through on the right side of the

fabric, and the stitch feels bumpy. Turn the dial to a lower

number to loosen the needle thread tension.

q

Needle thread (top thread)

w

Bobbin thread (bottom thread)

e

To loosen tension

r

Right side (top side) of fabric

t

Wrong side (bottom side) of fabric

Summary of Contents for MXL50

Page 1: ...Instruction Book...

Page 2: ......

Page 56: ...54 Stitch Chart...

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ...812 800 054 EN...