AAASewing.com

16

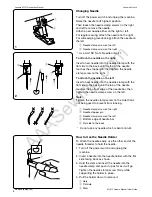

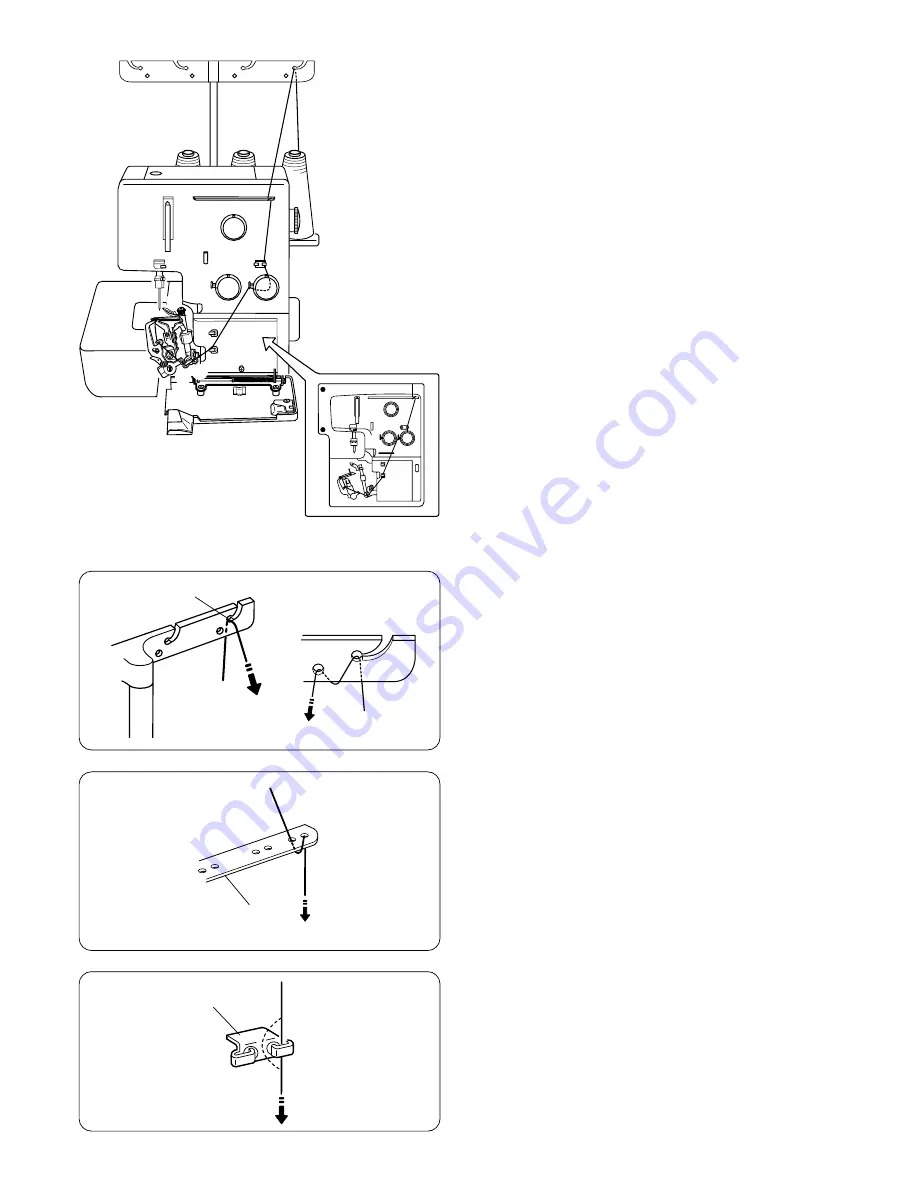

• Threading the Lower Looper

Open the looper cover and side cover.

Place the spool of thread on the right side spool pin.

*

The points to thread for lower looper are marked

in green.

*

A convenient threading chart is placed on the

machine body inside the looper cover.

1. Draw the thread through the right side thread

guide from back to front:

A

*

If the thread is coming out from the thread guide

groove, pass the thread through the thread guide

hole again as shown:

B

q

Thread guide

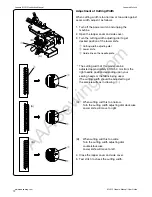

2. Pass the thread through the holes on the right side

of the thread guide plate as illustrated.

w

Thread guide plate

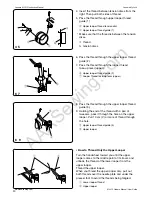

3. Pass the thread through the right side of the

looper thread guide, by sliding the thread from

left to right.

e

Looper thread guide

1

2

3

(A)

(B)

3

2

1

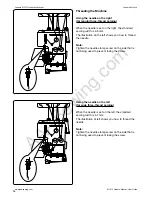

q

w

e

q

w

e

r

t

y

o

!0

u

!1

i

Janome ML213 Instruction Manual

Janome My Lock

www.aaasewing.com

ML213 Owners Manual/ User Guide