19

MECHANICAL ADJUSTMENT

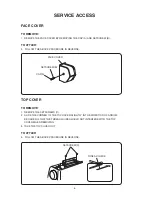

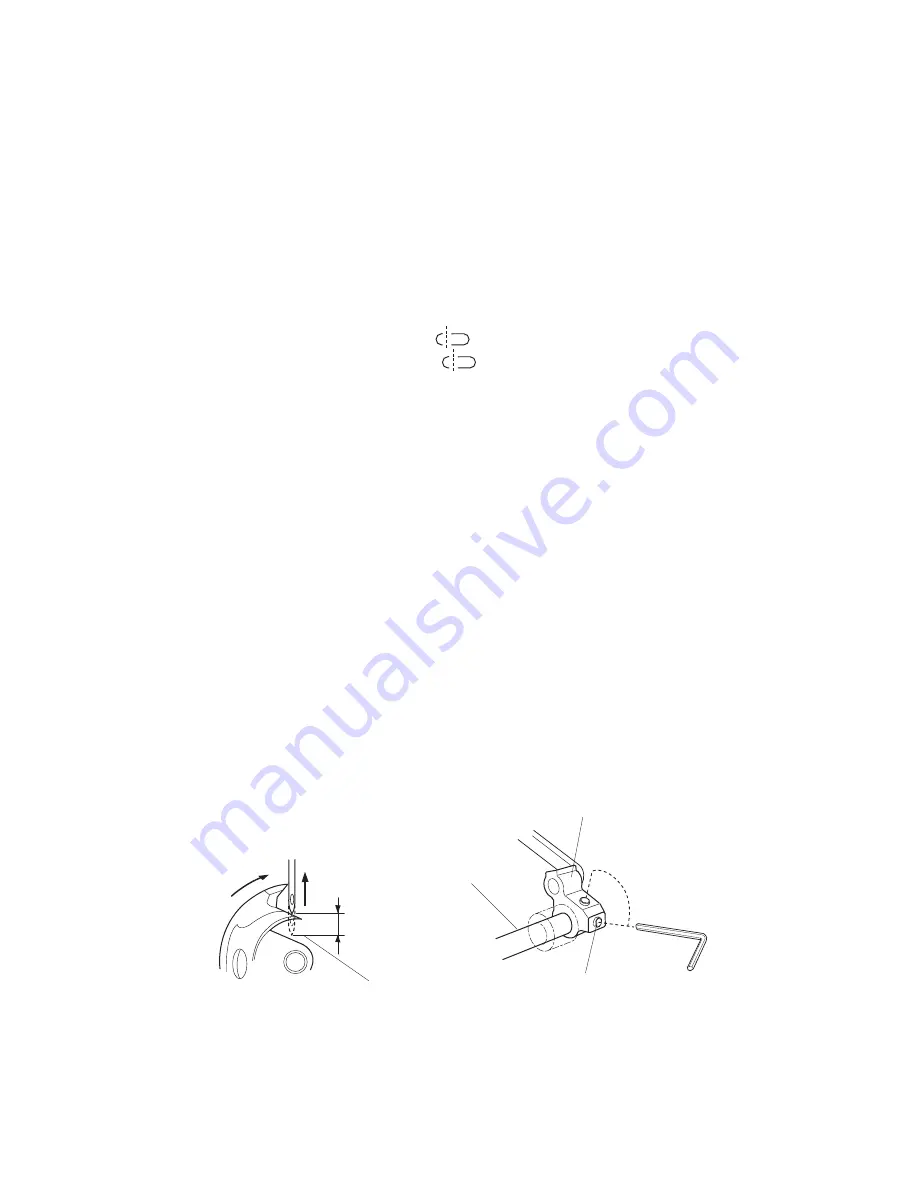

NEEDLE TIMING TO SHUTTLE

TO CHECk:

thE hEight of thE nEEdlE point from itS lowESt point of travEl Should BE

in thE rangE of 1.45-1.95 mm whEn thE tip of thE ShuttlE hook juSt mEEtS thE

lEft SidE of thE nEEdlE at thE lEft nEEdlE poSition.

ADJUSTMENT PROCEDURE:

1. SEt thE pattErn SElEctor dial at " ".

for modEl nExt 40, SElEct dial at " ", width SElEctor dial at " 0 ".

2. rEmovE thE BaSE (SEE pagE 7).

3. opEn thE ShuttlE covEr.

4. rEmovE thE ShuttlE racE ring.

5. turn thE handwhEEl toward You until thE tip of thE ShuttlE hook mEEtS

thE lEft SidE of thE nEEdlE.

6. looSEn thE lowEr Shaft crank arm ScrEwS (a).

7. whilE holding thE ShuttlE hook So it doESn't turn, turn thE handwhEEl

toward You until thE nEEdlE comES to itS lowESt poSition.

thEn, furthEr turn thE handwhEEl to raiSE thE nEEdlE aBout 1.7 mm from

itS lowESt poSition.

8. tightEn thE ScrEwS (a).

9. turn thE handwhEEl toward You to chEck if thE hEight iS in thE rangE of

1.45-1.95 mm.

if it iS not in thiS rangE, rEpEat thE aBovE procEdurE.

10. attach thE ShuttlE racE ring.

11. attach thE BaSE.

lowEr Shaft crank arm

ScrEwS (a) (2)

1.45–1.95 mm

lowESt poSition

lowEr Shaft

Summary of Contents for NH15

Page 1: ...1 SERVICE MANUAL MODEL NH15 PARTS LIST...

Page 23: ...23 WIRING 1 WIRING FOR MACHINE SOCKET UNIT L M M MOTOR L LAMP M L 120V 240V...

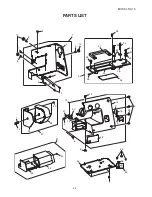

Page 34: ...34 MODEL NH15 PARTS LIST 1 2 3 4 4 5 6 7 8 9 10 11 12 13 14 8 4 15 16 17 8 8 18 19...

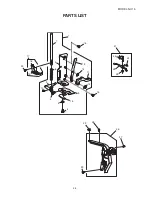

Page 38: ...38 MODEL NH15 PARTS LIST 1 2 3 9 5 8 6 7 4...

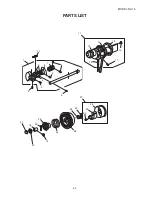

Page 40: ...40 MODEL NH15 PARTS LIST 2 8 1 4 5 7 6 3 9 10 11...