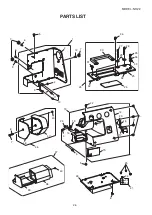

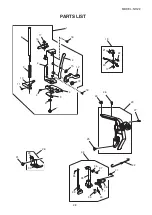

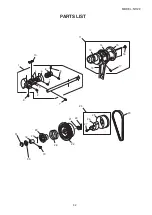

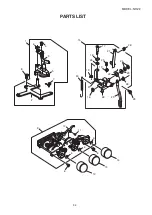

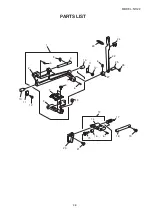

KEY PARTS

NO. NO.

DESCRIPTION

29

PARTS LIST

MODEL: NH22

308611106

308060001

735222009

000101404

735025000

000070506

000138307

303017101

735027002

735028003

000111500

735029004

000001609

735030008

000013903

740051001

000002105

000081005

739605002

739017001

739018002

739019003

310504700

310066004

000101703

000115205

000024505

310621003

301801009

301505002

660106001

740617001

753629109

000023009

740047004

000160102

000113306

740048005

753027008

740049006

000103808

740052002

Presser bar base plate (unit)

Presser bar base plate

Needle drop adjusting plate

Setscrew 4x6

Needle bar supporter stopper

Washer

Bolt 4x8

Presser bar

Presser bar spring

Presser bar bracket

Hexagonal socket screw 4x8

Presser foot lifter

Snap ring E-5

Tension release lever

Snap ring CS-5

BH regulating lever

Snap ring E-3

Setscrew 4x8

Tension release arm (unit)

Tension release arm base

Tension release arm

Tension release spring

Tension regulator (unit)

Thread guide

Setscrew 4x12

Setscrew TP4x6

Spring pin 1.6x18 (K)

Presser foot (unit)

Presser foot holder

Zigzag foot

Thumb screw

BH lever (unit)

BH lever (unit)

Spring pin 1.6x4

BH lever supporter

Adjustable lock nut 4

Socket screw 4x10

BH lever base plate

Friction spring

BH lever spring

Setscrew 3x5

BH shifting rod

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42