18

MECHANICAL ADJUSTMENT

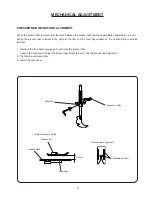

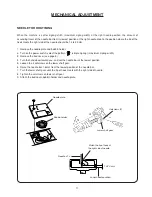

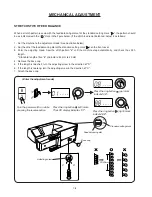

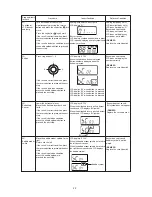

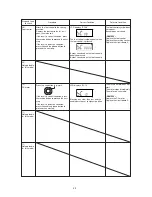

STRETCH STITCH FEED BALANCE

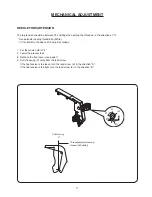

When a stretch pattern is sewn with the feed balancing dial set at the standard setting mark '' '', the pattern should

be as indicated with the '' '' mark in the figure below. (If the stitch feed is not balanced, adjust it as follows:

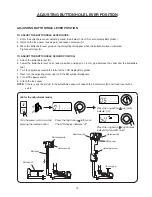

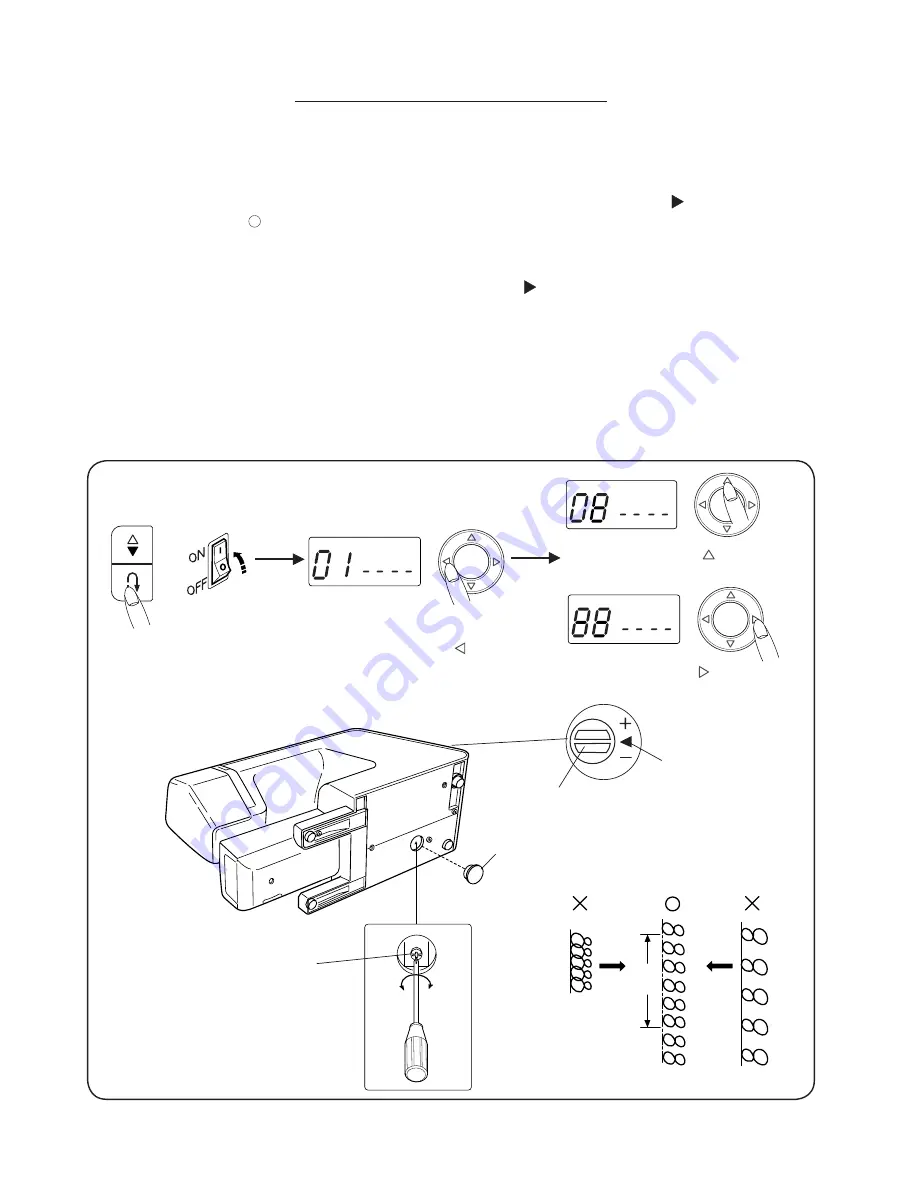

1. Set the machine to the adjustment mode (See illustration below).

2. Set the slit of the feed balancing dial at the standard setting mark '' '' on the front cover.

3. Enter the adjusting mode. Sew the stitch pattern "8" until the machine stop automatically, and check the stitch

length.

* Standard length of five "8" characters: 32 mm to 40 mm

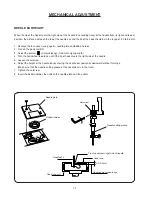

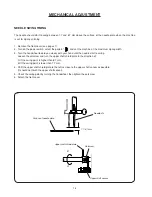

4. Remove the base cap.

5. If the length is too short, turn the adjusting screw in the direction of "D".

6. If the length is too long, turn the adjusting screw in the direction of "C".

7. Attach the base cap.

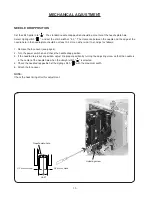

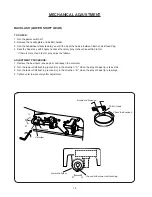

(Enter the adjustment mode)

Turn the power switch on while

pressing the reverse button.

Press the ring button (left) mark.

The LCD display indicates "01".

Press the ring button (up) mark

indicate "08".

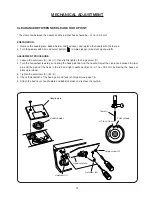

32-40mm

C

D

Adjusting screw

Feed balancing dial

Standard setting mark

Base cap

Press the ring button (right) mark

indicate "88".

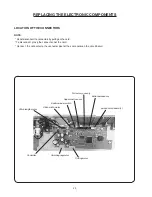

Summary of Contents for NH40

Page 1: ...SERVICE MANUAL MODEL NH40...