13

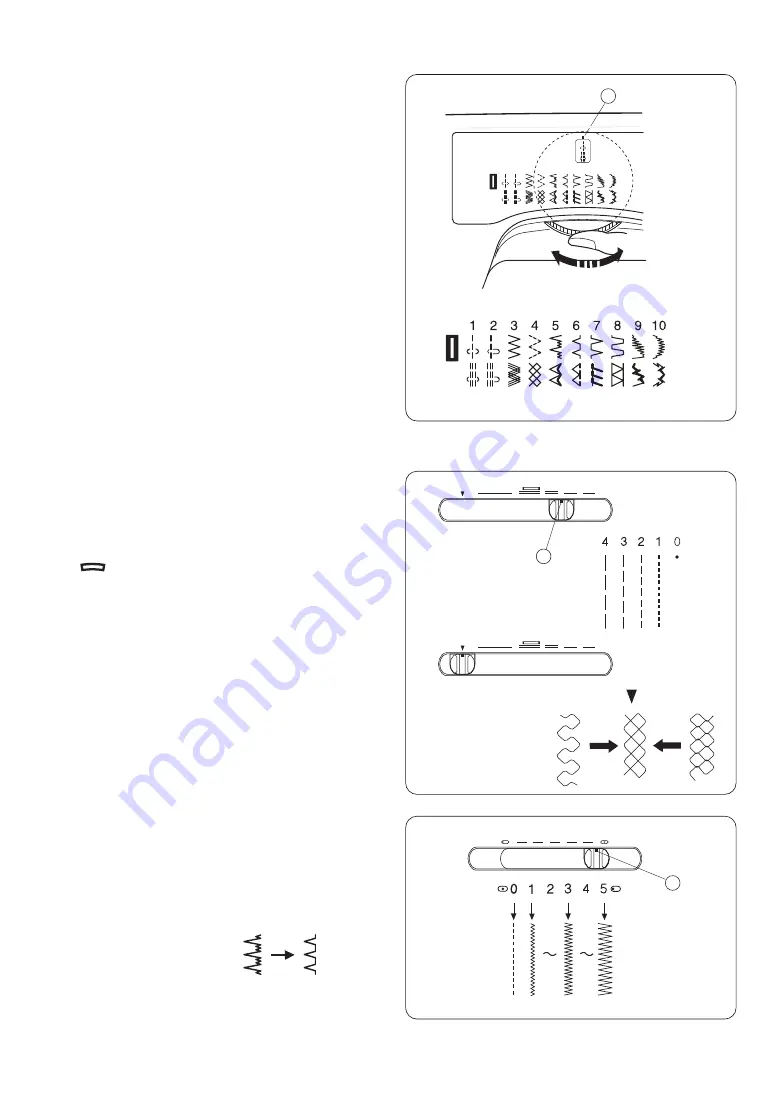

When the stitch width is narrow, the right side of the pattern is

cut off.

(Example: Pattern 5)

Stitch Width Control

Turn the stitch width control to set the setting mark at the

desired stitch width.

The higher the number, the wider the stitch width.

q

Setting mark

1

1

Pattern Selector Dial

Raise the needle and presser foot. Turn the pattern selector

dial to set the setting mark at the symbol corresponding to the

desired pattern.

q

Setting mark

Turn the stitch length control to set the setting mark at the desired

stitch length.

The higher the number, the longer the stitch length.

q

Setting mark

• “ ” is the recommended setting for buttonhole stitching.

• Adjust the stitch length control in the 0.5–4 range when you

sew the zigzag stitch.

• Set the stitch length control at “S.S.” to sew the stretch stitch

pattern sewing.

• If the stretch stitch pattern is uneven, slide the stitch

length control in the direction of “S” to compress it, or “L” to

expand it.

Stitch Length Control

Note :

Raise the needle above the fabric, when you turn the stitch

width control.

BH

BH 1 2 3 4 5 6 7 8 9 10

0

5

1

2

3

4

4

3

2

1

0

STRETCH

L

S

4

3

2

1

0

STRETCH

L

S

L

S

1

Width [5]

Width [3]