Page 12

Quilt Maker 15 User Manual

2022.02

Optional Accessories

Quilt from the Back Kit

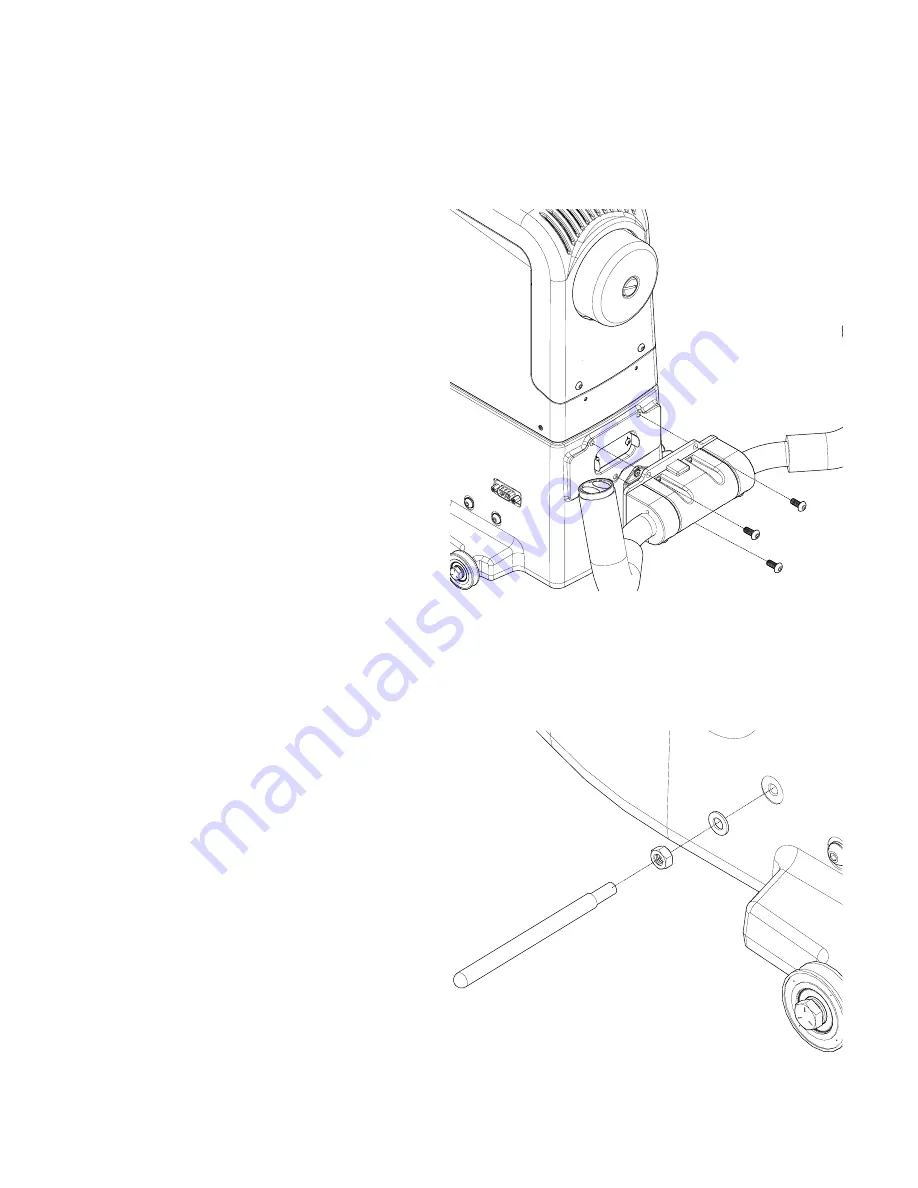

To install the Rear Handlebar

NOTE: Make sure that the machine is off

before installing the rear handlebar. The

main power switch must be in the O (off)

position.

1. Slightly loosen the two Philips screws on the

rear handlebar connection cover with a #1

Phillips screwdriver (not provided). Do NOT

remove the screws.

2. Pull off the plastic cover. It protects the

rear handlebar connection. Do NOT

remove the screws.

3. Re-tighten the two screws. They hold

the connection board to the machine.

4. You will need three M5 x 12 SKB ZN screws for

the rear handlebars (included in the Quilt from

the Back Kit) and a 3mm hex wrench.

5. Align the three holes in the handlebars with

the holes on the back of the machine.

6. Attach with the three screws. Tighten securely.

To install the Laser Pin

1. You will need the laser pin, washer and nut.

2. Screw the nut all the way onto the laser pin.

3. Slide the washer onto the laser pin threads and

screw the laser pin all the way into the side of

the machine.

4. While holding the laser pin, firmly tighten the

nut with the 8mm wrench (provided).

Summary of Contents for Quilt Maker 15

Page 1: ...15 Quilting Machine INSTRUCTION MANUAL...

Page 56: ...www janome com...