3

Sew Mini

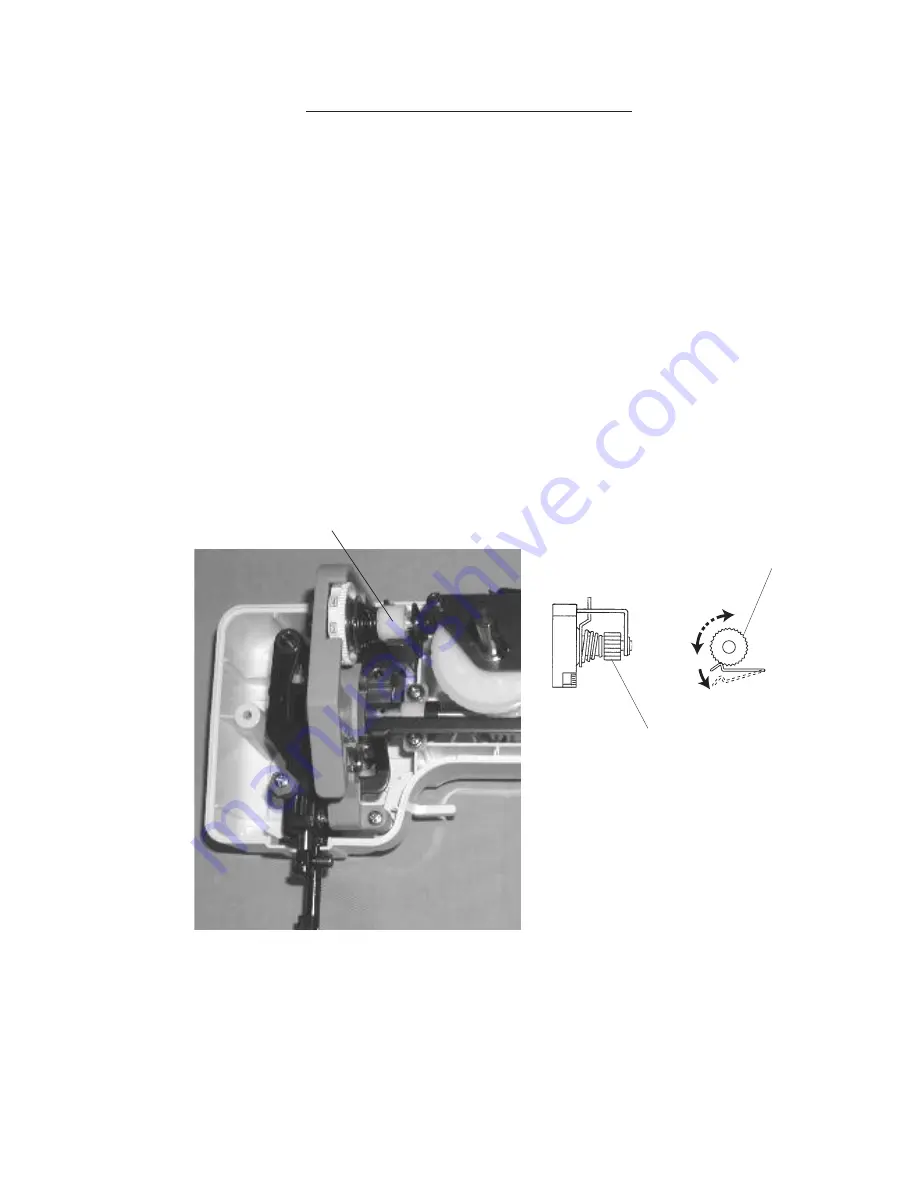

ADJUSTING THREAD TENSION

TO ADJUST

1. Remove the face cover and the front cover.

2. Turn the adjusting screw (C) in the direction of (A) when the upper thread tension is too

tight.

Turn the adjusting screw (C) in the direction of (B) when the upper thread tension is too

loose.

3. Attach the front cover and the face cover.

(C)

(C)

(B)

(A)

(C)

TO CHECK

The standard upper thread tension should be 75 - 90g when pulling the thread (polyester

thread #50) with setting the tension dial at “4”.

(Make sure the foot should be lowered.)

If the tension is out of the standard range, adjust it as follows: