7

Replacing mechanical parts

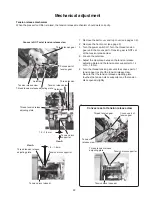

Needle threader hook

To remove:

1. Push down the threader lever as far as it will go and

hold it in place. Loosen and remove setscrew.

2. Release the threader lever slowly while holding the

threader unit to disengage it from the threader shaft.

3. Disassemble the threader unit and replace the threader

hook. Refer the following part number when ordering

service parts.

862627005: Hook holder (unit)

To attach:

1. Assemble the threader unit and attach them to the

threader shaft by inserting the shaft into the holes.

2. Make sure the pin is engaged in the slot.

Secure the threader unit to the threader shaft by

tightening setscrew.

Adjust the needle threader hook position

(see page 23).

Setscrew

Threader lever

Threader unit

Hook holder (unit) (862627005)

Setscrew

Pin is engaged in the slot