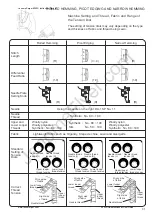

JanomeFlyer.com

18

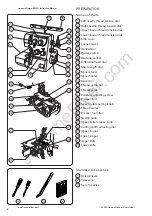

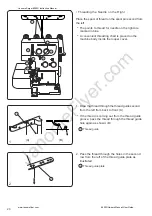

(A)

(B)

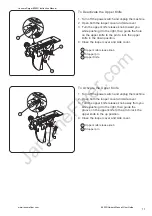

• Threading the Upper Looper

Place a spool of thread on the spool pin second

from the right.

*

The points to thread for upper looper are marked

in red.

*

A convenient threading chart is placed on the

machine body inside the looper cover.

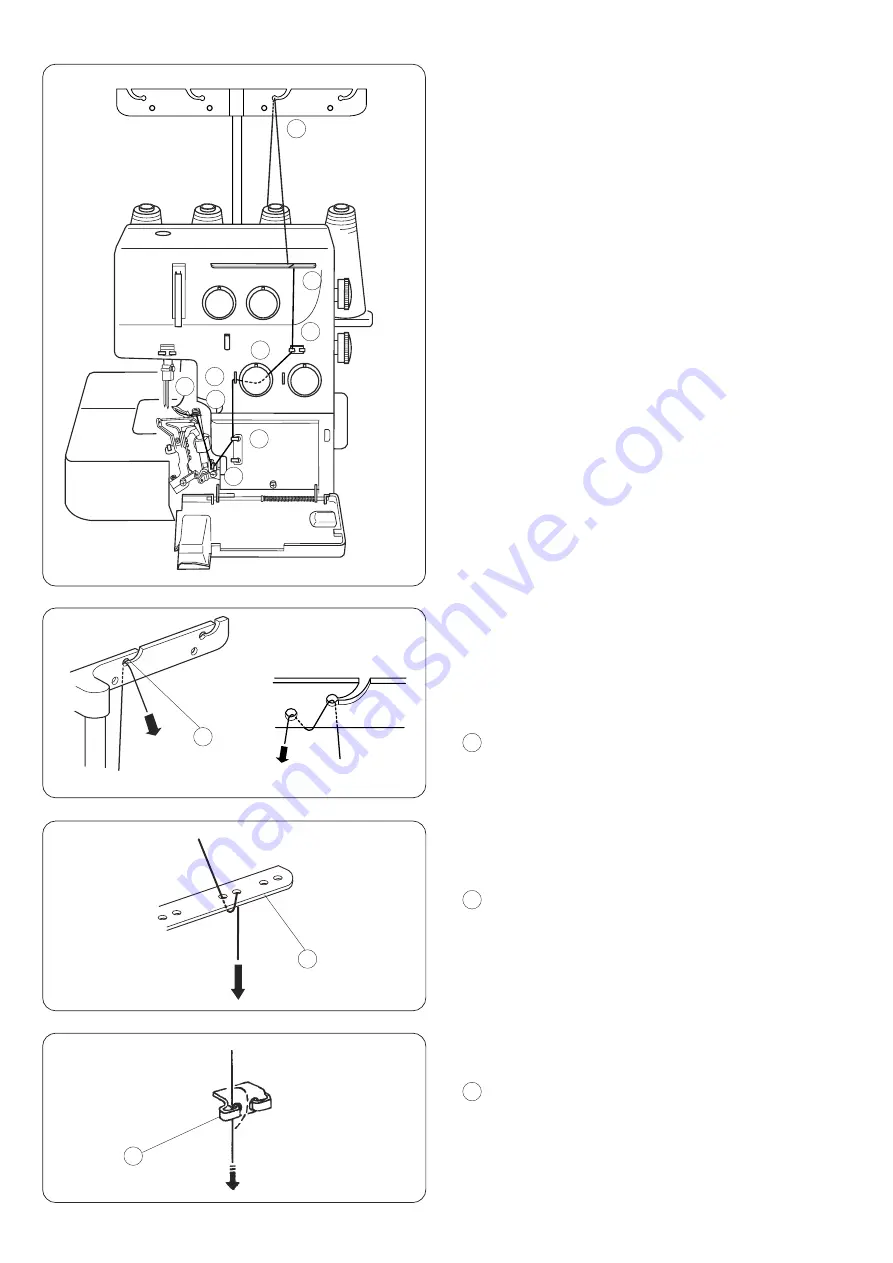

1. Draw the thread through the thread guide second

from the right from back to front: (A)

1

Thread guide

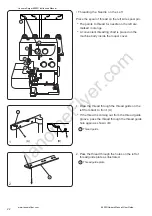

2. Pass the thread through the holes in the second

row from the right of thread guide plate as

illustrated.

2

Thread guide plate

3. Pass the thread through the left side of looper

thread guide sliding the thread from right to left.

3

Looper thread guide

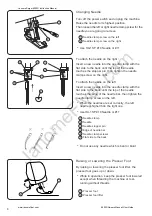

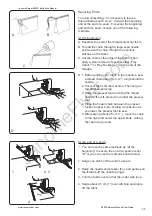

1

2

3

4

5

6

9

1

2

3

1

2

3

*

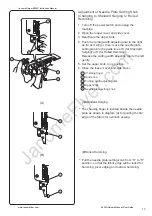

If the thread is coming out from the thread guide

groove, pass the thread through the thread guide

hole again as shown: (B)

8

7

Janome Serger 8002D Instruction Manual

www.janomeflyer.com

8002D Owners Manual/ User Guide