AAASewing.com

4

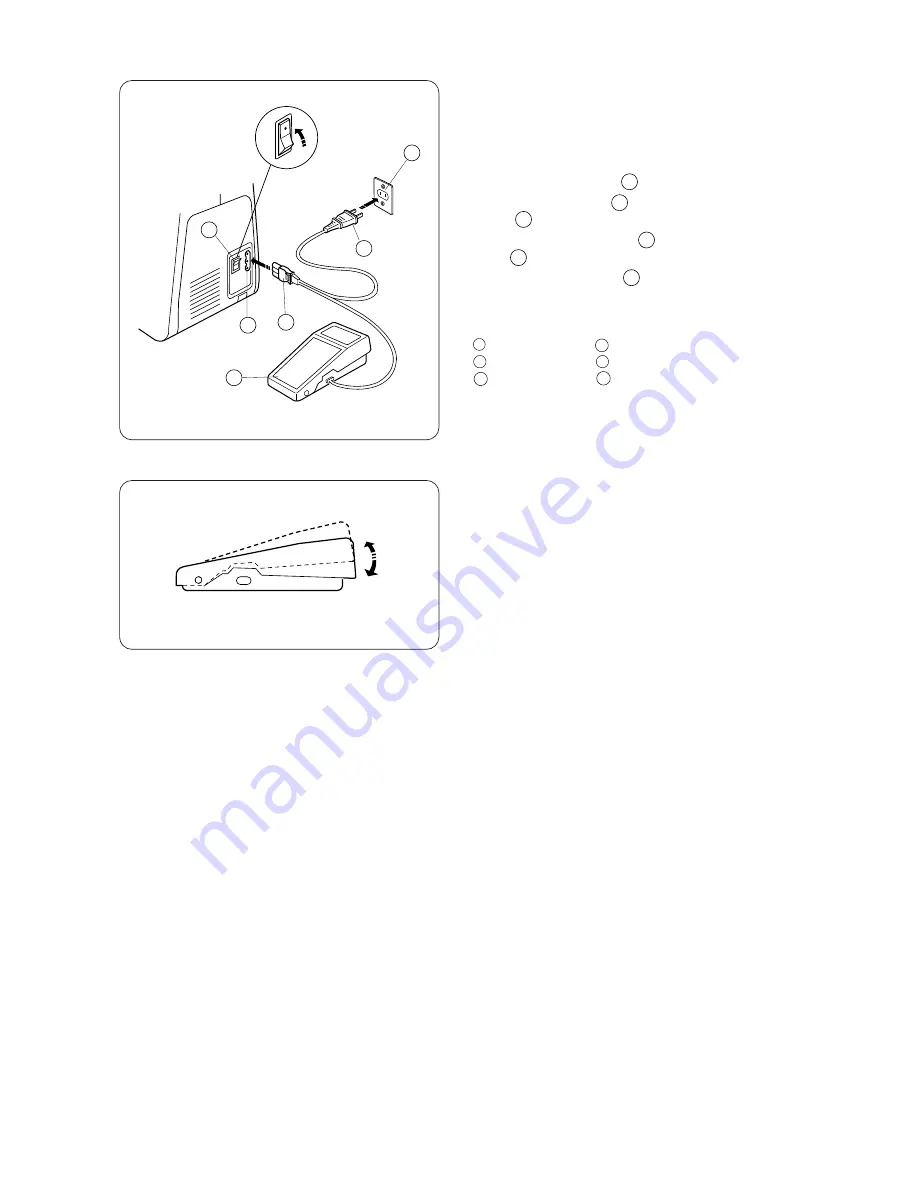

Connecting the Machine to the Power Supply

Before connecting the power cord, mark sure the voltage

and frequency shown on the machine conform to your

electrical power.

1. Turn off the power switch .

2. Insert the machine plug into the machine

socket .

3. Insert the power supply plug into the

outlet .

4. Turn on the power switch to turn on the

power and sewing light.

Foot control

Sewing speed can be varied by the foot control.

The harder you press on the control, the faster the

machine runs.

1

2

3

4

5

2

1

2

3

4

5

6

1

Power supply plug

Power switch

Outlet

Machine socket

Machine plug

Foot control

2

3

4

5

6

Janome US2014 Instruction Manual

www.aaasewing.com

US2014 Owners Manual/ User Guide