DRUM SANDER FOR WOODEN FLOORS

ED 98

PG.

12/19

INSTRUCTION MANUAL

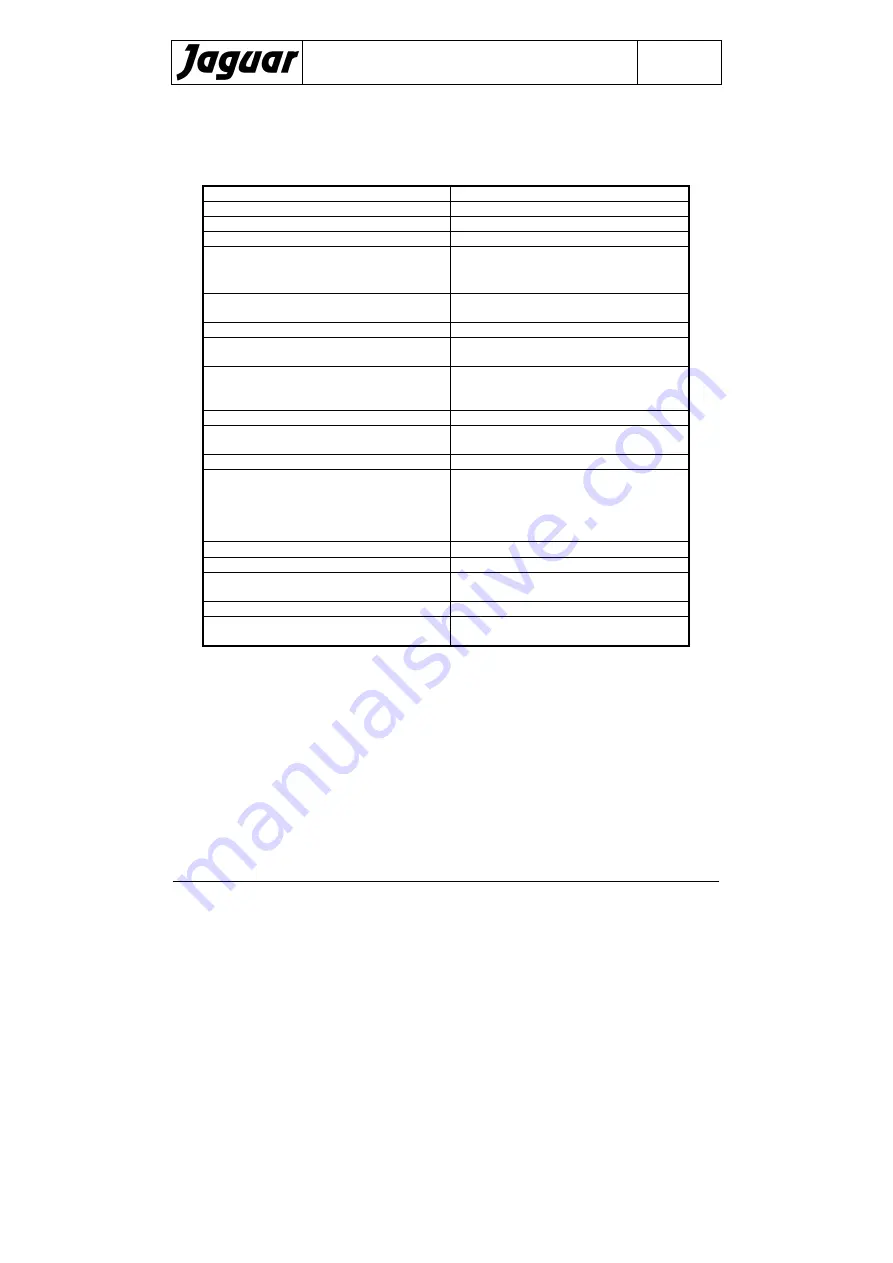

MACHINE CHARACTERISTICS

ABRASIVE DIMENSION FOR DRUM:

203 x 480 mm RING

ROLLER WIDTH

200 mm

ROLLER DIAMETER

150 mm

ROLLER SPEED

2700 RPM

MOTOR ( A43 ) EUROPEAN AND UK

( A45 ) USA

230V-

∼

50 Hz 1,5 kW

240V

∼

50 Hz 1,5 kW

115V

∼

60 Hz 1,5 kW

HANDGRIPS

POSSIBILITY OF HEIGHT ADJUSTMENT:

2 POSITION

CONTROL LEVER

OPERATED FROM THE HANDGRIPS

LEVEL CONTROL

BY MEANS OF AN OFF-CENTRE PIN ON

THE WHEEL

SAFETY MOTOR PROTECTION

BY MEANS OF LEVER

N. 9 FIG. A

RELEASING THE LEVER THE MOTOR

STOPS

WHEELS

Ø 80 mm REPLACEABLE

BEARINGS

LIFELONG LUBRICATED RADIAL

BEARING

ROLLER PRESSURE ADJUSTMENT

CONTINUOUSLY ADJUSTABLE

NOISE OF THE MACHINE WORKING IDLE

(continuous and cautious level of acoustic

pressure A measured at the distance of 0,4 m

from handgrips and from 1,5 m from ground

level )

80 dB(A)

MACHINE DIMENSIONS

320 x 810 x 1070 mm

NET WEIGHT

45 kg

PACKAGE DIMENSION

2 boxes 660 x 370 x 640 mm e 340 x 220 x

880 mm

GROSS WEIGHT

56 kg

DOTAZIONE

STANDARD

DUST BAG, USE KEYS, USE AND

MAINTENANCE MANUAL