A rolling door is a large heavy object that moves

with the help of springs under extreme tension and

follow these instructions.

electric motors. Moving objects and springs under

tension and electric motors can cause serious injuries

or death. For your safety and the safety of others,

WARNING!

Use proper lifting equipment and correct

lifting procedures to avoid damage or injury.

CAUTION

SAFETY INFORMATION

POTENTIAL HAZARD

EFFECT

PREVENTION

MOVING DOOR

ELECTRICAL SHOCK

HIGH SPRING TENSION

WARNING

Could result in death

or serious injury

Keep people clear of opening while Door is moving.

DO NOT allow children to play with the Door Operator.

DO NOT operate a Door that jams or one that has a broken spring.

Turn off power before removing operator cover.

When replacing operator cover, make sure wires are not pinched or near

moving parts.

Operator must be properly grounded.

DO NOT try to remove, repair or adjust springs or anything to which Door

spring parts are fastened, such as steel brackets or other like items.

Repairs and adjustments must be made by a trained door system

technician using proper tools and instructions.

OVERVIEW OF POTENTIAL HAZARDS

WARNING

Could result in death

or serious injury

WARNING

Could result in death

or serious injury

Overhead doors are large, heavy objects that move with the help of springs under high tension and electric motors. Since

moving objects, springs under tension, and electric motors can cause injuries, your safety and the safety of others depend

on you reading the information in this manual. If you have questions or do not understand the information presented, call

your nearest service representative.

In this section, and those that follow, the words "Danger", "Warning", and "Caution" are used to emphasize important safety

information. For example:

if not avoided, may result in injury or property damage.

which, if not avoided, could result in death

if not avoided, will result in death or serious injury.

or serious inury.

Door must be fully opened when making adjustments.

Repairs and adjustments must be made by a trained rolling door systems

technician using proper tools and instructions.

WARNING

Could result in death

or serious injury

PAGE 1

ASTA DOOR CORPORATION

DANGER:

Indicates an imminently hazardous situation which,

WARNING:

Indicates a potentially hazardous situation

CAUTION:

Indicates a potentially hazardous situation which,

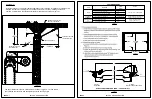

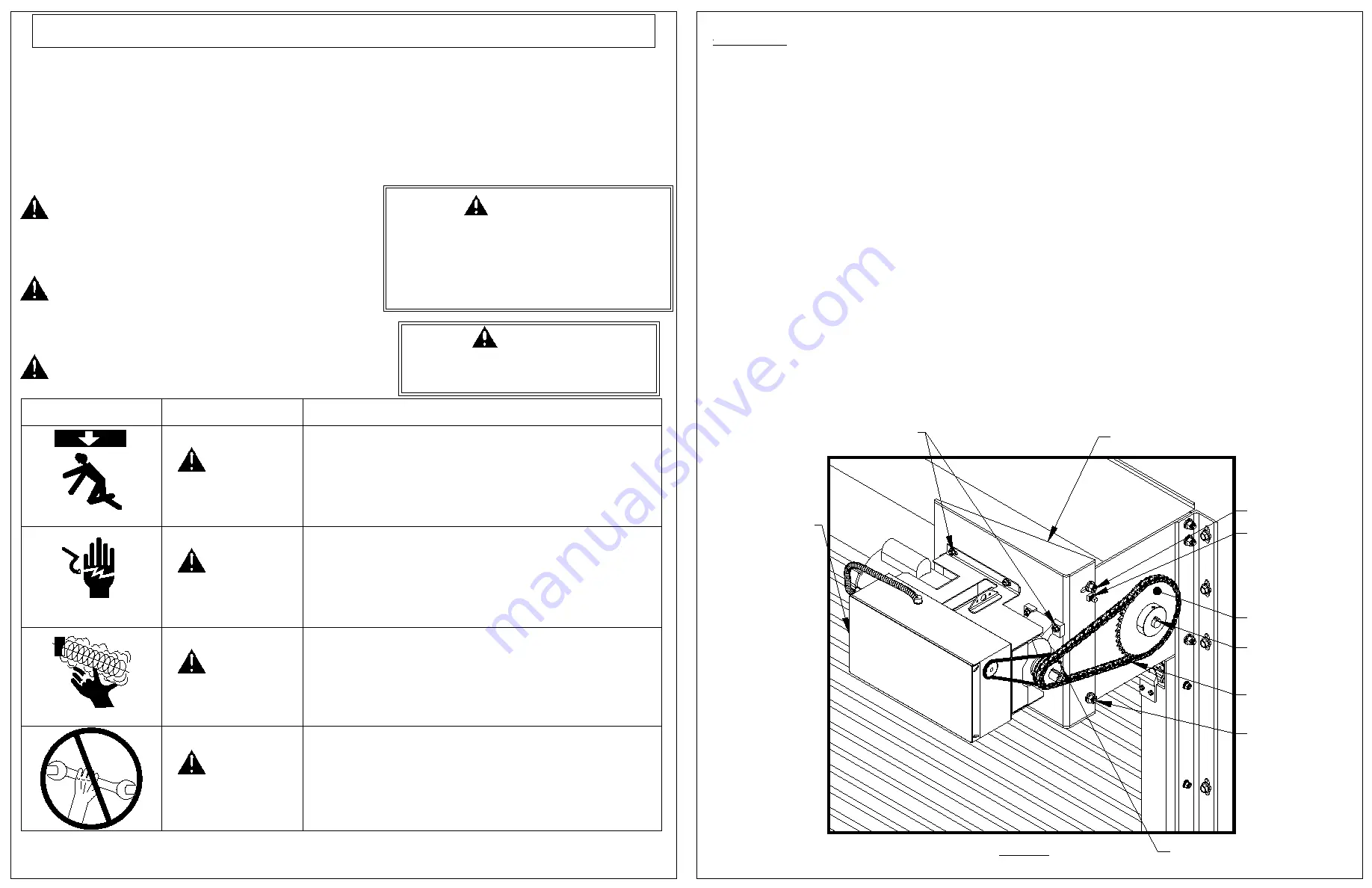

FIGURE C-1

PAGE C-1

ASTA DOOR CORPORATION

Appendix "C"

1. Verify the barrel and guide assemblies are properly installed and that all

fasteners are tightened securely.

2. Procedure for installation of motor operator.

a. Attach the operator to bracket using the supplied hex bolts,

flat washers, lock washers and hex nuts as shown in Figure C-1.

b. Install motor operator and bracket assembly to the drive side headplate

with two 1/2" -13 NC X 1 1/4" carriage bolts as shown in Figure C-1.

c. Push the assembly toward wall as far as possible for drive chain

installation, and temporarily secure the two carriage bolts as shown in

Figure C-1.

d. Install the drive shaft sprocket with supplied key way.

e. Align the drive shaft and operator sprockets and tighten set screws.

f. Size & install the supplied #50 roller chain and secure with #50 master link.

g. Loosen the operator carriage bolts and tighten the roller chain by pulling

the assembly away from the wall leaving approximately 3/4" slack in chain.

h. Tighten operator bracket carriage bolts and set screw to lock the bracket

in place and to retain roller chain setting during future operation.

MOTOR OPERATOR

OPERATOR BRACKET

SET SCREW

1/2" CARRIAGE BOLT

PIVOT BOLT

OPERATOR FASTENERS

KEY WAY

DRIVE SPROCKET

OPERATOR SPROCKET

#50 ROLLER CHAIN

ASTA Door Corporation 500 Series FIRE DOOR

Motor Operator Installation