page 7 of 8

MODEL 424

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

jarvis.products.corp@snet.net

TEL. 860-347-7271 FAX. 860-347-6978 WWW.

jarvisproducts.com

JARVIS

6205001a

®

4.1 Your power hand saw is not designed for regular

use in starting its own hole by sinking blades

through a surface, commonly called “plunge

cutting”. If attempted, the operator must:

a. Keep the saw blade as parallel to the work

as possible.

b. Immediately, as the blade makes contact

with the work piece, start to draw the saw

back slowly from the starting point.

c. Repeat the operation outlined in “b”, if nec-

essary.

d. Have room to draw the saw at least 4--6 in-

ches before cutting through a one inch

thickness.

e. Do not force the saw blade, but keep it

moving slowly on the draw back from the

starting point. After a break through cut

has been made and the end of the blade sup-

port extends through the material at least

1--1/2 inches, the saw may be tipped to a

normal cutting angle.

5 ALWAYS KEEP A SHARP BLADE ON THE

SAW:

5.1 Cutting with a dull or badly worn blade can

overload the saw and cause damage from over-

heating.

5.2 New blades can be purchased from

Jarvis

.

MAINTENANCE INSTRUCTIONS

IMPORTANT: ALWAYS DISCONNECT THE COM-

PRESSED AIR SUPPLY IN ACCORDANCE WITH

OSHA’S LOCKOUT/TAGOUT PROCEDURES (29 CFR

1910.147) WHEN INSTALLING OR REMOVING THE

BLADE. ALWAYS DISCONNECT THE AIR SUPPLY IN

ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT

PROCEDURES (29 CFR 1920.147) BEFORE PERFORM-

ING ANY MAINTENANCE OR REPAIRS

.

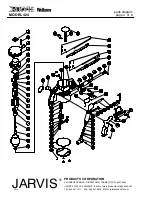

Item numbers: refer to the parts diagram on page 4.

1 DAILY:

1.1 Inspect all hoses for cuts and abrasions and re-

place as necessary.

1.2 Check all fittings and connections for leaks and

tighten or replace as necessary.

1.3 An air filter/regulator/lubricator (

Jarvis

part

number 3022003) must be installed in the air

supply line.

Keep the lubricator filled at all

times

.

1.4 Make sure that the saw is working correctly.

Note: The air supply must be connected to per-

form this maintenance check only.

Depress

the trigger and the tool should start.

Release

the trigger and the tool should stop.

If

the tool malfunctions, repair or remove it from

service immediately.

Always use two hands when starting and stop-

ping the tool. Continue holding the saw firmly

with both hands until the blade comes to a com-

plete stop

.

2 WEEKLY:

2.1 Remove the bottom cover plate from saw hous-

ing (item 38).

2.2 Apply

Jarvis

1315 White Grease

to the pinion

and gear, bearing and stud assembly (items 19

and 30).

3 MONTHLY:

3.1 The gear case should be kept 1/3 full of grease.

To check the grease level, remove the bottom

cover plate (item 23) and its gasket (item 24).

Check more frequently for saws that are used

daily. Use

Jarvis

1315 White Grease.

4 BLADE REMOVAL:

NOTE: Your

Jarvis

Wellsaw is equipped with a hex key

(item 58) for removing the blade. This wrench is located

in the housing directly behind the blade support.

4.1 Insert the hex key through the hole in the outer

end of blade (item 43) and pull the blade to the

outer end of its stroke.

operation and

maintenance instructions