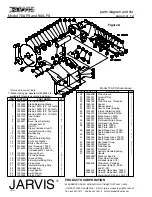

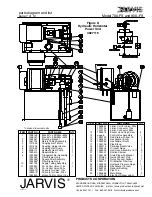

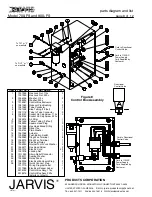

parts diagram and list,

specifications and installation instructions

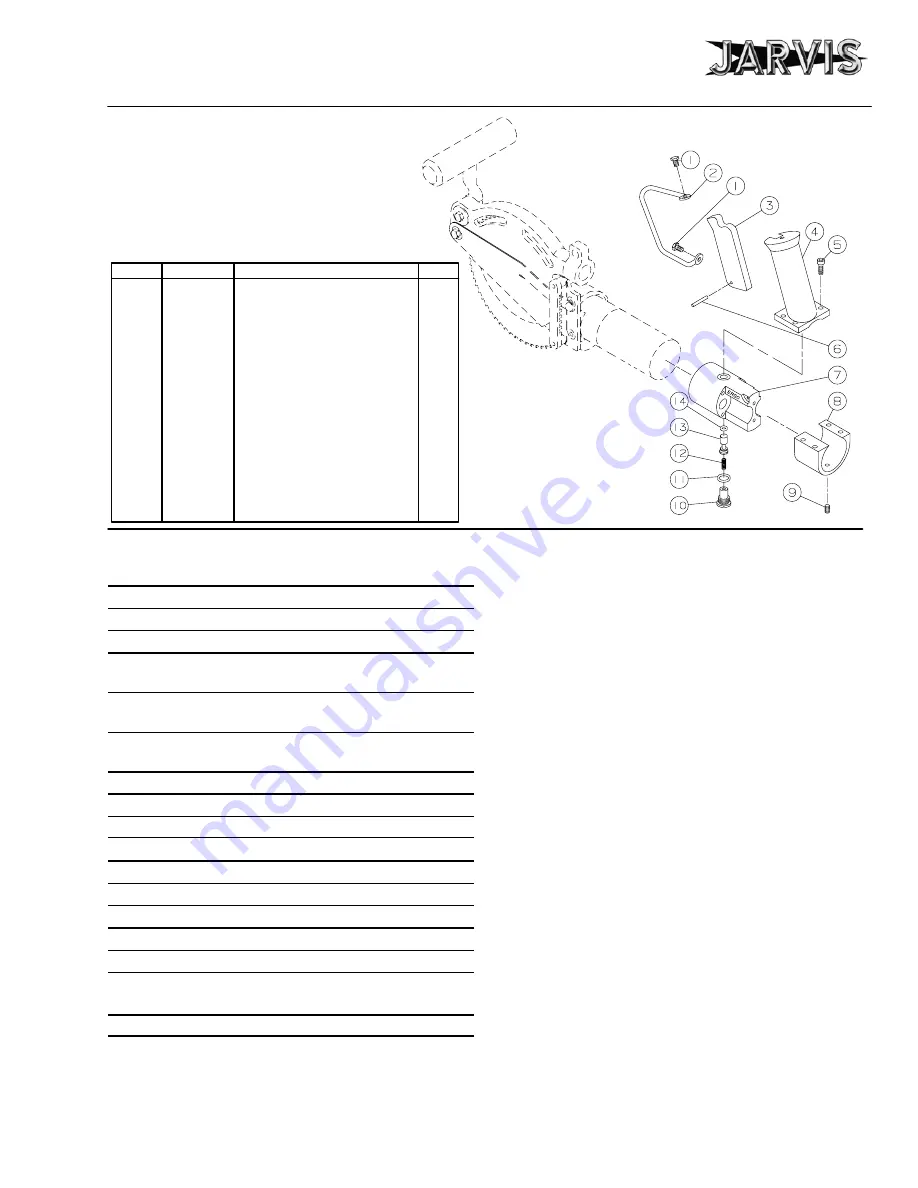

Model 700-FS and 900--FS

page 9 of 12

JARVIS

6207014::::

®

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926

UNITED STATES OF AMERICA E--MAIL.

jarvis.products.corp@snet.net

TEL. 860-347-7271 FAX. 860-347-6978 WWW

.jarvisproducts.com

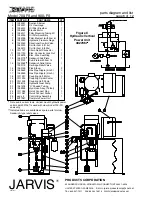

1

1055283

Hex Head Screw

2

2

1024149

Trigger Guard

1

3

1018131

Trigger Lever

1

4

1019150

Handle

1

5

1055398

Socket Head Cap Screw

4

6

1010286

Dowel Pin

1

7

1061630

Hydraulic Manifold

1

8

1012088

Clamp Bracket

1

9

1055312

Set Screw

1

10

1051150

Plug

1

11

1035245

O--ring

1

12

1014086

Spring

1

13

1039034

Valve Plunger with item 14

1

14

1035279

O--ring

1

3019151

Ergonomic Handle Kit

(items 1--14)

ITEM PART NO.

PART NAME

QTY

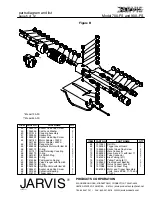

Figure F

Ergonomic Handle Kit

Model 700--FS shown above.

SPECIFICATIONS

Model 700-FS and 900--FS

Motor Power

2.5 hp

1867 W

Blade Speed

at 3.5 gpm

2200 rpm

Control Handle

Single / Pneumatic

Blade Diameter (700FS)

6.5 in

165 mm

Blade Diameter (900FS)

8.0 in

203 mm

Cutting Depth (max. 700FS) 1.9 in

48 mm

Cutting Depth (max. 900FS) 2.6 in

67 mm

Overall Length (700FS)

17 in

425 mm

Overall Length (900FS)

18.75 in

476 mm

Weight (with hoses)

10 lbs

4.7 kg

Vibration

less than (<) 120 dB

< 1.0 m/sec

2

Noise

(one meter from tool)

88 dB

Hydraulic Power Unit

Motor Power

5 hp

3728 W

Operating Voltage

230/460 V, 3 ph, 60 Hz

Hose Length

16 ft

5 m

Oil Capacity

20 gal

76 L

Oil Visc. at 100

°

F/40

°

C 200 SUS

46 ISO

Overall Dimensions (l x w x h)

28 x 23 x 28 in

711 x 584 x 711 mm

Weight (without oil)

200 lbs

91 kg

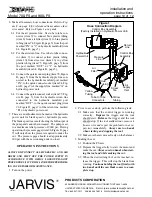

INSTALLATION INSTRUCTIONS

ALWAYS DISCONNECT THE POWER SUPPLY IN

ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT

PROCEDURES (29 CFR 1910.147) BEFORE PERFORM-

ING ANY REPAIRS OR MAINTENANCE.

ALL WIRING MUST BE DONE IN ACCORDANCE WITH

NATIONAL, STATE AND LOCAL ELECTRICAL CODES.

1 Install the FS saw above the work station from a ba-

lancer.

Jarvis

part number 4042044 is available.

1.1 The saw should have enough travel to allow the

operator to reach the entire work area.

2 Install the hydraulic power unit overhead or on the

floor behind the work station.

2.1 Avoid excessive height and long pipe runs.

3 Wire the power unit. The power unit requires three

phase, 60 Hertz, 230/460 volts to the motor and

single phase, 60 Hertz, 115 volts to the control box.

4 Equip the power unit with a master pilot light switch

at the operator’s station.

This will facilitate shut-

down in case of an equipment failure.

5 Fill the oil reservoir with a USDA approved pre-

mium grade hydraulic fluid (viscosity: 200 S.U.S. at

100

°

F or 46 ISO at 40

°

C).

Never run the power unit

without oil.