maintenance instructions

Model MCS 300

page 11 of 16

®

JARVIS

6201010:.

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926

UNITED STATES OF AMERICA E--MAIL.

jarvis.products.corp@snet.net

TEL. 860--347--7271 FAX. 860--347--6978 WWW. j

arvisproducts.com

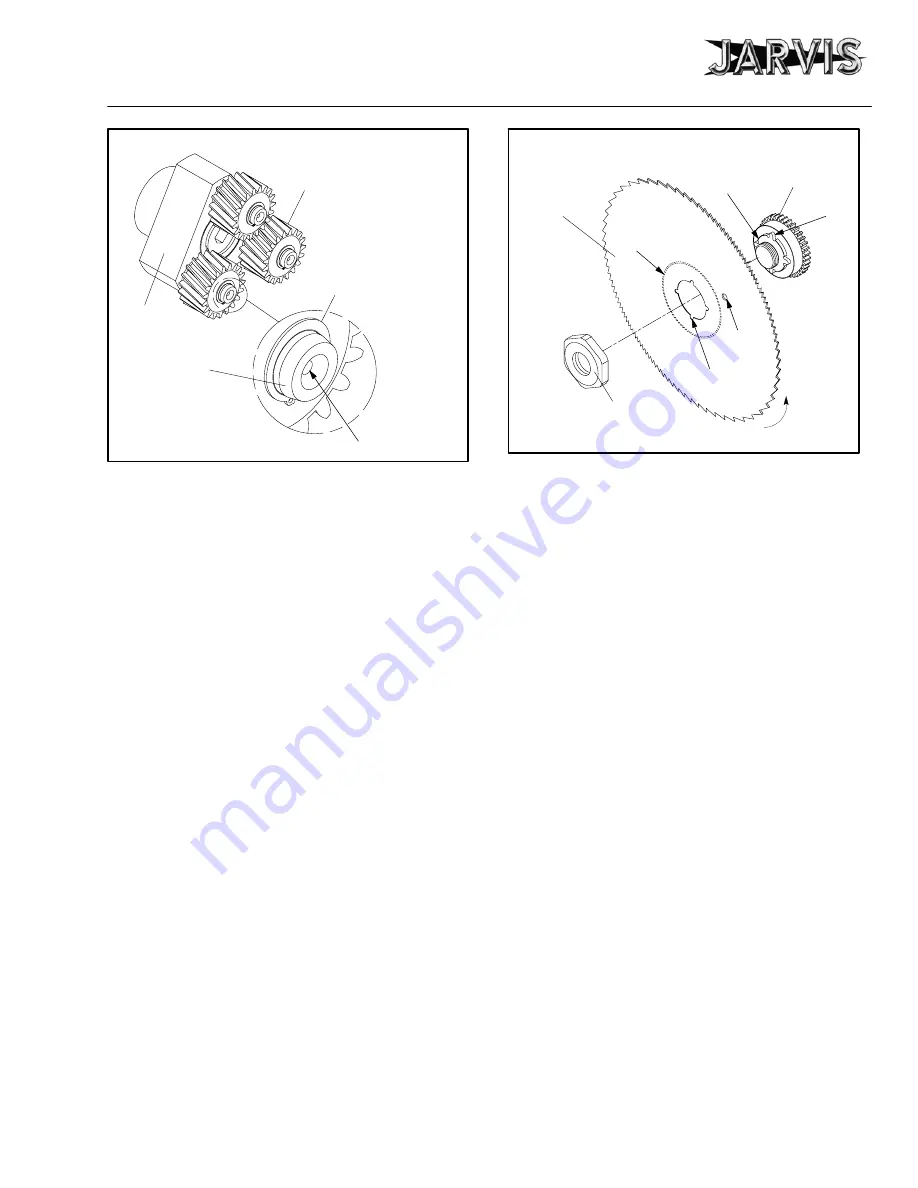

Figure 1

Bearing and Gear Lubrication

PLANET GEAR

HOLE TO

LUBRICATE

NEEDLE BEARING

DOWEL PIN

RETAINING

RING

PLANETARY

HUB

3 AS NECESSARY:

3.1 Clean and inspect circular blade.

Refer to sec-

tions 4 and 5 for blade removal and installation

procedures.

3.2 Disassemble, clean and inspect the spur gear

housing assembly, planetary housing assembly,

air motor assembly, and handle and valve hous-

ing assembly.

Refer to sections 6 through 12 as

a procedural guide.

4 CIRCULAR BLADE REMOVAL:

4.1 Remove locking lever (item 1), depth gage

screw (item 2) and depth gage plate (item 3) if

applicable.

4.2 Remove the blade nut (item 4).

Jarvis

wrench

1061361 is available.

See Figure E on page 8.

4.2.1 Place an awl or small screwdriver through

the outer hole in blade to prevent it from ro-

tating.

4.3 Remove the saw blade (item 5) and sharpen or

replace as necessary.

5 CIRCULAR BLADE INSTALLATION:

5.1 Reverse procedures and steps outlined in section

4.

See notes below. Refer to Figure 2 as a guide.

5.1.1 To ensure proper fit and safe operation, the

hub of the saw blade (item 5) must face to-

ward and fit securely on the extended lip of

the spur gear.

5.1.2 Make sure notched areas on the saw blade

are aligned with ears on the spur gear.

LIP

BLADE

BLADE

NUT

SPUR

GEAR

EAR

OUTER

HOLE

HUB ON

OTHER

SIDE

NOTCHED

AREA

Figure 2

Blade Installation

BLADE

ROTATION

DIRECTION

5.1.3 When tightening blade nut (item 4), insert

an awl or small screwdriver through the out-

er hole in the blade to prevent blade from

turning.

Jarvis

wrench 1061361 is avail-

able.

See Figure E on page 8.

6 SPUR GEAR HOUSING DISASSEMBLY:

6.1 Remove blade as described in section 4.

6.2 Remove flat head screws (item 55).

6.3 Remove blade guard assembly and auxiliary

handle assembly (items 6--9) as a complete unit

from spur gear housing (item 18).

6.4 Remove dowel pins, o--ring and u--cup seal

(items 10--12) from blade guard only if neces-

sary.

6.5 Remove cheese head screws (item 77) and lock

washers (item 76). Remove spur gear housing

(item 18) and planetary housing (item 45) as a

complete unit from motor housing (item 60).

6.5.1 Set motor housing and rear handle assembly

aside.

6.6 Remove hex head screws (item 30) and lock

washers (item 29). Separate planetary housing

assembly (items 24--45) as a complete unit from

spur gear housing (item 18).

6.7 Remove spur gear hex nut (item 20),

left hand

thread.

6.7.1 Use a 5 mm allen wrench to hold spur gear

pin (item 14) from moving while unscrew-

ing spur gear hex nut (item 20),

left hand

thread. Note: Use heat to loosen hex nut if

necessary

.