maintenance instructions

Model MCS 300

page 15 of 16

®

JARVIS

6201010:.

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926

UNITED STATES OF AMERICA E--MAIL.

jarvis.products.corp@snet.net

TEL. 860--347--7271 FAX. 860--347--6978 WWW. j

arvisproducts.com

8.4 Remove retaining rings (item 38).

8.5 Remove planetary gear pins (item 41), planet

gears (item 39) and needle bearings (item 40)

from planetary gear hub (item 35).

Use a drive

punch if necessary.

8.6 Remove planetary gear pins (item 41) and

needle bearings (item 40) from planet gears

(item 39).

Jarvis

special tool 8039168 is avail-

able.

See Figure E on page 8. Be careful not to

score any parts.

8.7 Remove retaining ring (item 34).

8.8 Remove pinion gear (item 43), ball bearing

(item 33), inner race (item 42) and key (item 32)

from planetary housing (item 45).

Lightly tap

gear housing end of planetary housing with ny-

lon mallet to dislodge pinion gear assembly.

Use and arbor press if necessary.

8.9 Remove key (item 32).

8.10 Press ball bearing (item 33) and inner race (item

42) from pinion gear (item 43).

8.11 Remove o--ring (item 24).

8.12 Press needle bearing (item 28) from planetary

housing (item 45).

8.13 Clean and inspect all parts for wear and replace

as necessary.

9 PLANETARY HOUSING ASSEMBLY:

9.1 Reverse procedures and steps outlined in section

8.

See notes below.

9.1.1 Make sure o--ring (item 24) is seated proper-

ly in planetary housing.

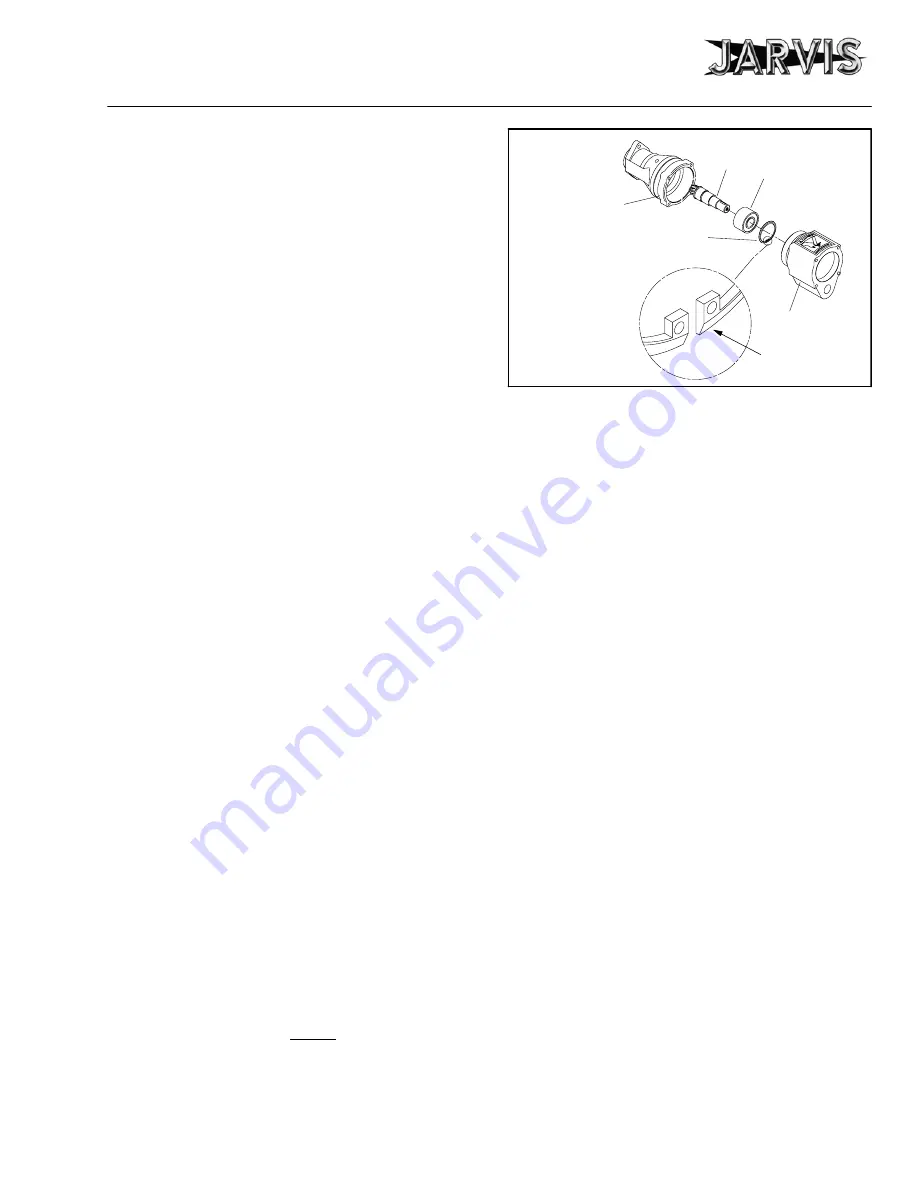

9.1.2 Make sure bevel end of retaining ring (item

34) is facing toward air motor housing

when installed into planetary housing (item

45).

See Figure 6.

AIR MOTOR

HOUSING

ROTOR

NOTE BEVEL

DIRECTION

RETAINING RING

Figure 6

GEAR HOUSING

BALL BEARING

10 MOTOR HOUSING DISASSEMBLY:

10.1 Remove cheese head screws (item 77) and lock

washers (item 76).

10.2 Separate the motor housing assembly and rear

handle assembly as a complete unit from plane-

tary housing assembly.

10.3 Separate the motor housing assembly from rear

handle assembly.

10.4 Slide motor housing assembly (items 62--69, 98

and 99) from motor housing (item 60).

For ease

of removal and installation, use a heat gun to ap-

ply heat to motor housing, if necessary.

10.5 Remove rotor screw (item 69). Use 12 mm

wrench on flats on rotor to prevent rotor from

turning.

10.6 Lift off rear motor plate (item 98) and ball bear-

ing (item 62) from air motor sleeve (item 68).

Use a drive punch if necessary. See note below.

10.6.1 Place drive punch in hole of rotor shaft and

lightly tap until rear motor plate and ball

bearing is free from rotor shaft.

10.7 Slide rotor and bearing assembly (items 62--67)

from air motor sleeve (item 68).

10.8 Remove dowel pins (item 99) if necessary.

10.9 Remove vanes (item 66).

10.10 Press ball bearing (item 62) from splined end of

rotor (item 65). Remove wave spring (item 63).

10.11 Remove o--ring (item 59) from motor housing

(item 60).

10.12 Clean and inspect all parts for wear and replace

as necessary.