specifications, installation

and operation instructions

Model MCS 300

page 9 of 16

®

JARVIS

6201010:.

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926

UNITED STATES OF AMERICA E--MAIL.

jarvis.products.corp@snet.net

TEL. 860--347--7271 FAX. 860--347--6978 WWW. j

arvisproducts.com

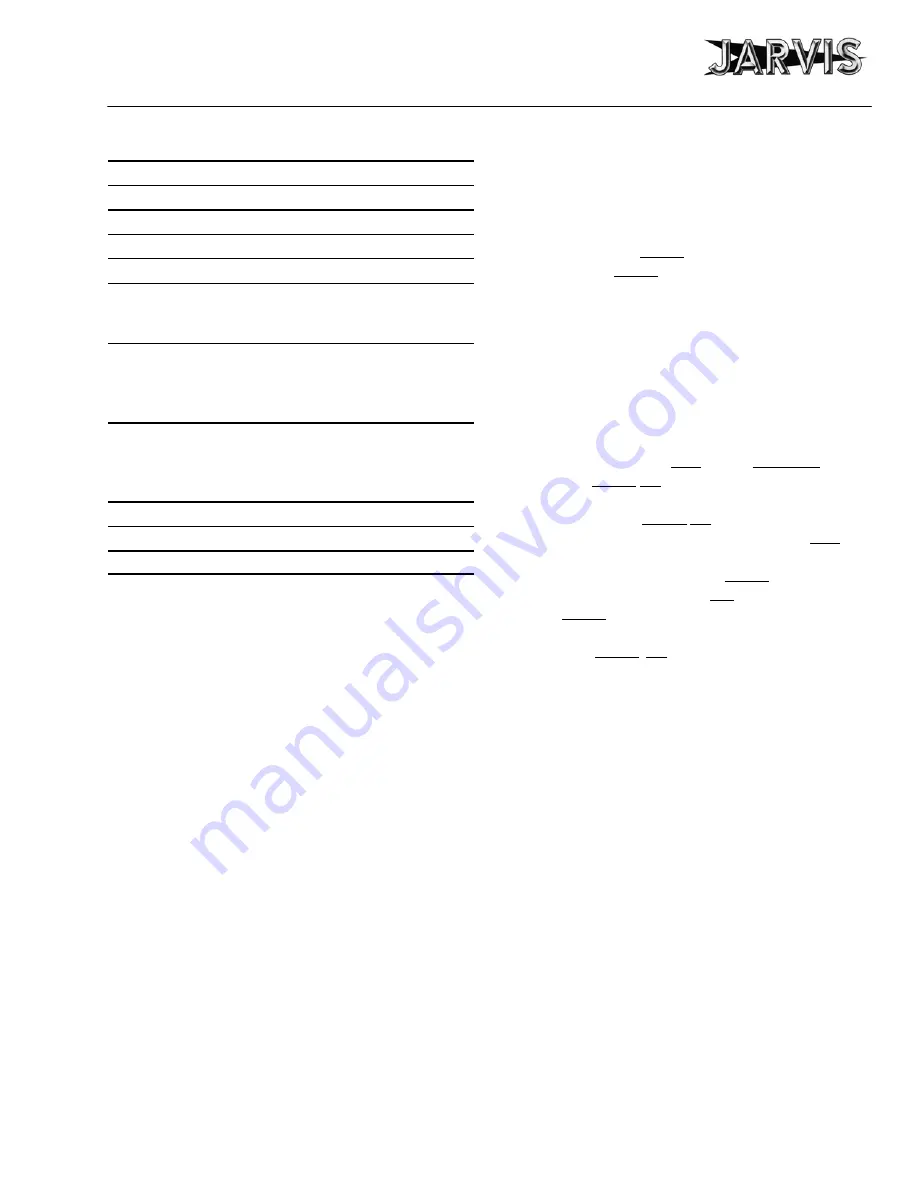

SPECIFICATIONS

Motor Power

2 hp

1500 W

Operating Pressure

90 psi

6.2 bar

Air Consumption at 90 psi 67 ft

3

/min

1.9 m

3

/min

Blade Speed

1150 rpm

Control Handle Single or Dual Trigger Pneumatic

Blade Diameter

9.0 in

229 mm

10.5 in

267 mm

12 in

305 mm

Cutting Depth (max)

9 inch blade

3 in

76 mm

10.5 inch blade

3.4 in

86 mm

12 inch blade

4.38 in

111 mm

Overall Length

9 inch blade

22.7 in

577 mm

10.5 inch blade

23.2 in

589 mm

12 inch blade

24.2 in

615 mm

Weight

15.5 lbs

7.0 kg

Vibration

less than (<) 125 dB < 1.78 m/sec

2

Noise (one meter from tool)

91 dB

INSTALLATION INSTRUCTIONS

1 Suspend the MCS 300 from a balancer.

Jarvis

part

number 4042040 is available.

2 Make the necessary air connection.

2.1 The required compressed air supply is 67

ft

3

/min at 90 psi (1.9 m

3

/min at 6.2 bar).

2.2 Refer to Figure B on page 5 for single trigger

tools.

2.3 Refer to Figure C on page 6 for dual trigger

tools.

OPERATION INSTRUCTIONS

1

Each day

, before you begin operation, go through

the following checklist:

1.1 Make sure that the compressed air supply is at

the correct pressure and that the lubricator is up

to the full mark. Use

Jarvis

Air Mist Lubricator

Oil

; if using a conventional air mist lubricator

set the feed rate at 8--10 drops per minute; if us-

ing a

micro fog

air mist lubricator set the feed

rate at 100 drops per minute.

Note:

Almost all

air mist lubricators are of the micro fog type

.

1.2 Make sure that the saw moves freely on the ba-

lancer.

1.3 Make sure that the saw is working correctly.

For Single Trigger Tools: Depress

the trigger

and the tool should start.

Release

the trigger and

the tool should stop.

If the tool malfunctions, re-

move it from service and report the problem to

your supervisor immediately.

Always use two hands when starting and stop-

ping the tool. Continue holding the saw firmly

with both hands until the blade comes to a com-

plete stop

.

For Dual Trigger Tools:

Make sure the dual

anti--tie down control handles are working cor-

rectly.

Depress

each trigger separately and the

tool should not start.

Depress

one trigger, then

pause one second and depress the other trigger

and the tool should not start. Repeat this proce-

dure reversing the triggers.

Depress

both trig-

gers simultaneously (within one half second of

each other) and the tool should start. With the

tool running,

release

one trigger and the tool

should stop. Continue holding the depressed

trigger and then depress the other trigger. The

tool should not start.

Repeat

this procedure

holding the other trigger.

If the tool malfunc-

tions, remove it from service and report the

problem to your supervisor immediately.

Always use two hands when starting and stop-

ping the tool. Continue holding the saw firmly

with both hands until the blade comes to a com-

plete stop

.

2 Making the cut:

2.1 Position the saw.

2.2 Depress the trigger(s) fully to start the saw and

make the cut.

Always use two hands when start-

ing the saw and while making the cut.

2.3 When the desired cut is reached, release the trig-

ger(s).

Continue holding the saw firmly with

both hands until the blade comes to a com-

plete stop

.

2.4 Withdraw the saw from the carcass.