maintenance instructions

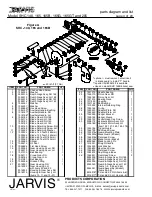

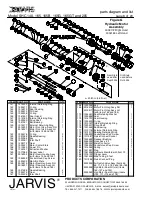

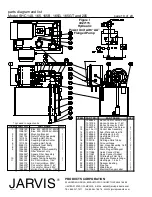

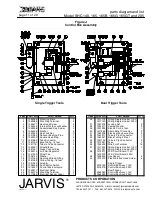

Model SHC 140, 165, 165B, 165G, 165GT and 205

page 18 of 20

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

sales@jarvisproducts.com

TEL. 860-347-7271

FAX. 860-347-6978

WWW.

jarvisproducts.com

JARVIS

6207016::::.

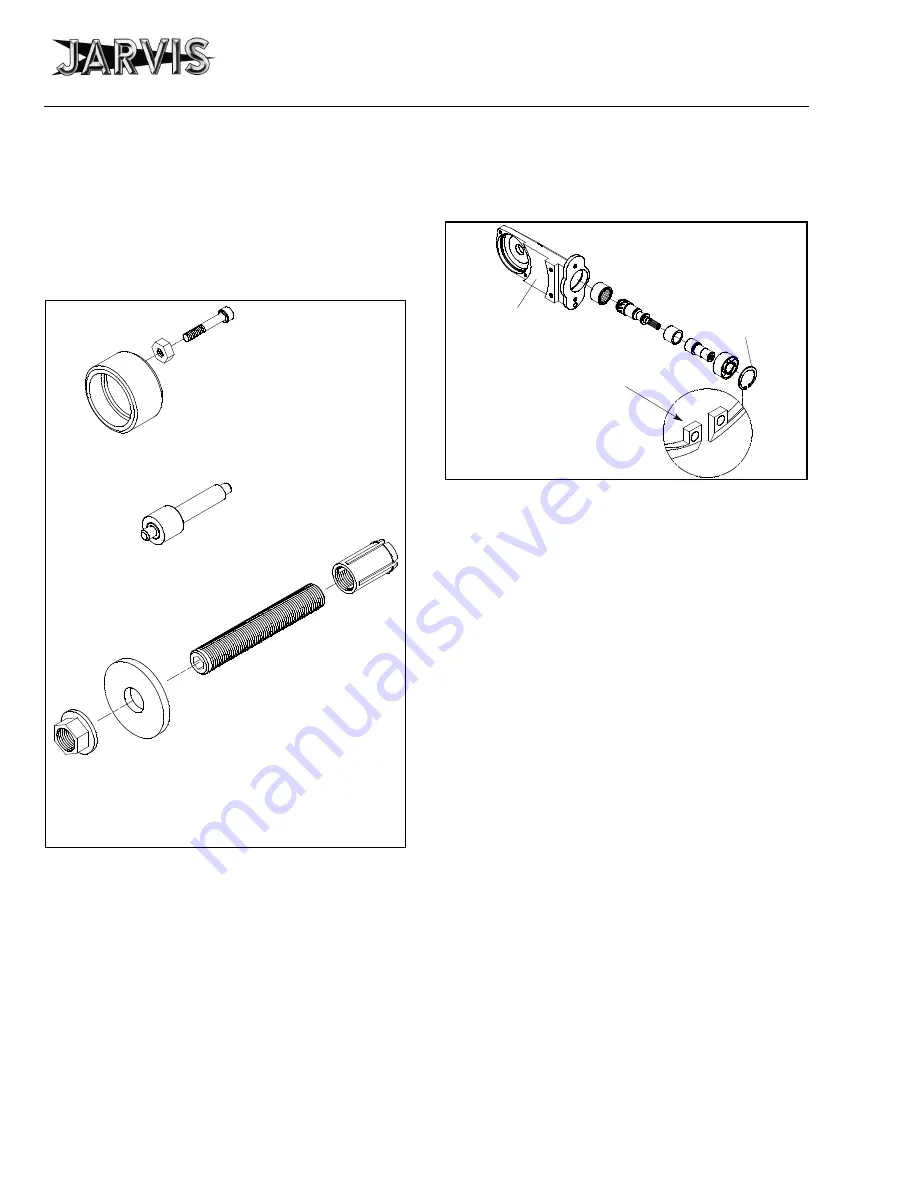

7.9 Disassemble the pinion gear.

7.9.1 Press the ball bearing (item 26) from the

coupling (item 25).

7.9.2 Press the coupling (item 25) from the pinion

gear (item 23).

7.10 Remove bearing race (item 24), if necessary.

7.11 Inspect all parts for wear and replace as neces-

sary.

Figure 4

Special Tools

8039139

Needle Bearing

Extraction Tool

8039140 or

8039152

Needle Bearing

Extraction and

Installation Tool

8039118

Needle Bearing

Extraction Tool

THE ABOVE TOOLS ARE RECOMMENDED FOR

PROPER AND EFFECTIVE ASSEMBLY AND DIS-

ASSEMBLY OF THE JARVIS MODEL SHC 140, 165,

165B, 165G AND 205 HYDRAULIC CIRCULAR

SAWS.

8039163 Complete

Tool Kit

8 GEAR HOUSING ASSEMBLY:

8.1 Reverse procedure outlined in section 7.

See

special notes below.

8.1.1

Jarvis

assembly tool 8039152 is available

for the installation of needle bearing (item

22).

See Figure 4.

Always press on the lip

that has the manufacturer’s markings.

Note:

Pressing the unmarked (and unhardened)

lip will deform and damage the bearing.

8.1.2 When installing internal retaining ring (item

27), make sure that the beveled edge faces

away from gear housing (item 21, 50 or 99).

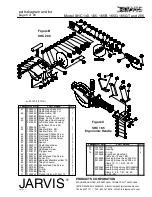

See Figure 5 below.

Retaining

Ring

Gear Housing

Note Bevel

Direction

Figure 5

Retaining Ring

Installation

9 Remember to install wave spring (item 95) in gear

head (item 99) before crown gear assembly (items

90--94).

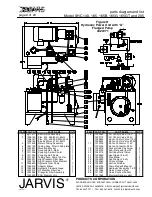

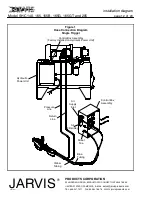

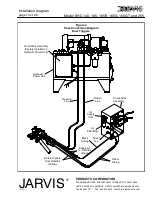

10 DRIVE SHAFT SEAL REPLACEMENT -- Old

Style:

Note: It is not necessary to disassemble the hydraulic

motor to replace the old style drive shaft seal. All compo-

nents of shaft seal cartridge (items 142--147) must be re-

placed with hydraulic motor seal kit, 3035058.

10.1 Separate the gear housing (item 21, 50 or 99) and

motor assembly as outlined in section 7, steps

7.1--7.3.

10.2 Remove the two screws (item 32) and remove

motor adapter plate (item 29, 52 or 121).

10.3 Remove the internal retaining ring (item 141)

and use the lip on the seal housing (item 143) to

gently lift the seal cartridge (item 142--147)

from the motor.

10.4 Inspect the drive shaft (item 148) for wear or

galling. If the shaft is only polished, proceed to

step 10.5. If shaft needs replacing, refer to sec-

tions 11 and 12.

10.5 Remove the internal retaining ring (item 147).

10.6 Lubricate the new seal (item 144) with

Jarvis

1315 White Grease

and install it in new seal

gland (item 146).