22

Spot

weldin

g

Note:

○

,1

Initial segment

:

Initial segment of 2T and 4T is set for automation welding. Welding specification of this

segment is -50%~+100% of that of process, displaying “0.5~2.0” at initial current with 0~10s. When time is set as 0,

initial segment is off. So if initial segment is needed, it is recommended to set as 1.30 with 0.5s. Initial segment of

program 4T can be set freely without being affected by process.

○

,2

Crater phase

:

It is applied to fill in the crater. This segment can be set freely but the specification is usually

smaller than that of process.

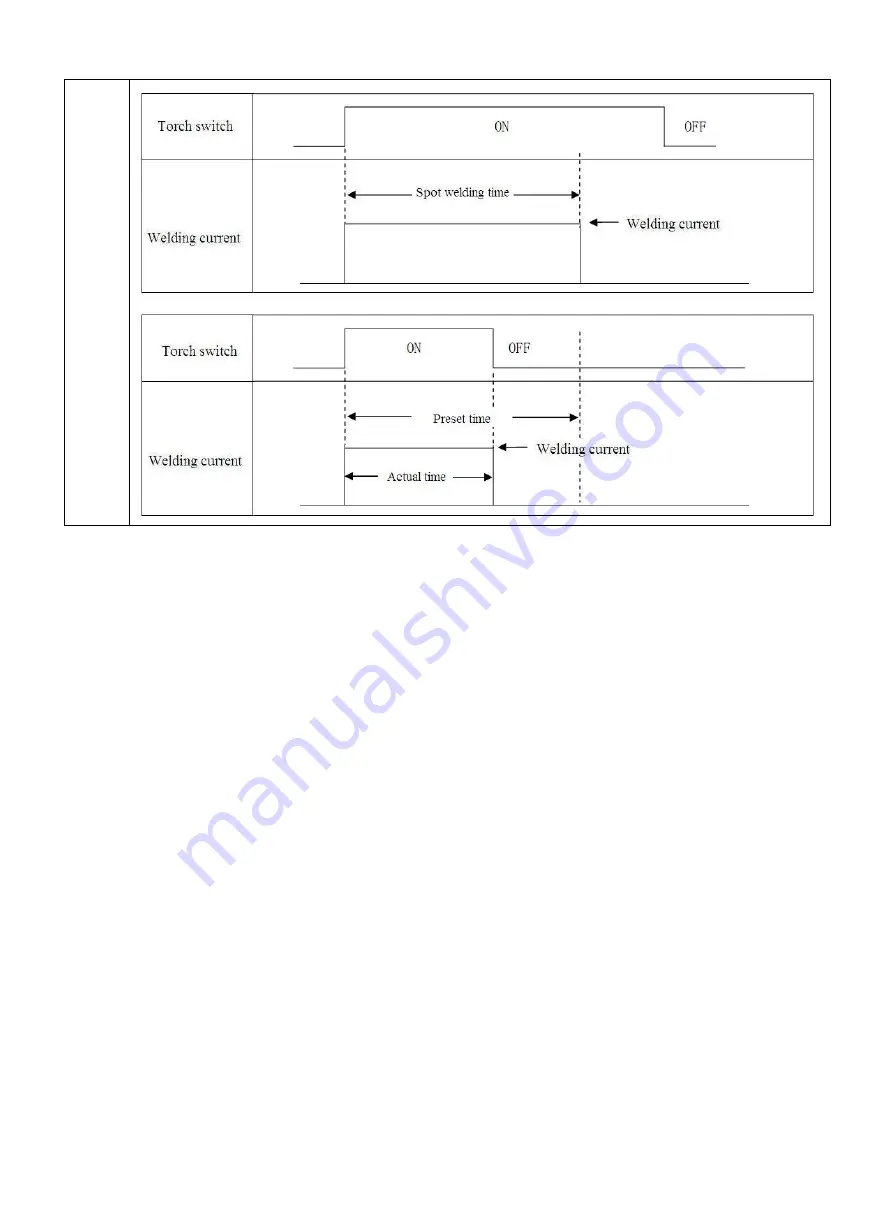

Summary of Contents for MIG 350P

Page 13: ...11 4 6 2 Separated machine installation Figure 4 3 ...

Page 19: ...17 3 Operation modes Table 5 2 DC MIG operation modes Modes Sketch map 2T 4T ...

Page 20: ...18 Repeat Spot weldin g 5 2 3 Pulse MIG 1 Synergic and Separate ...

Page 22: ...20 2T with initial crater 4T ...

Page 23: ...21 4T with initial segmen t Special 4T pro gram 4T ...

Page 40: ...38 7 Wiring Diagram ...

Page 42: ...40 ...